Silk/wool fiber dyeing method and post-dyeing sewage treatment device thereof

The technology of a sewage treatment device and a dyeing method is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, dyeing method, etc., which can solve the difficulty of dyeing silk/wool mixed fibers with the same color, large environmental pollution and pollutants. many problems, to achieve the effect of reducing sewage discharge, reducing environmental pollution and improving treatment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

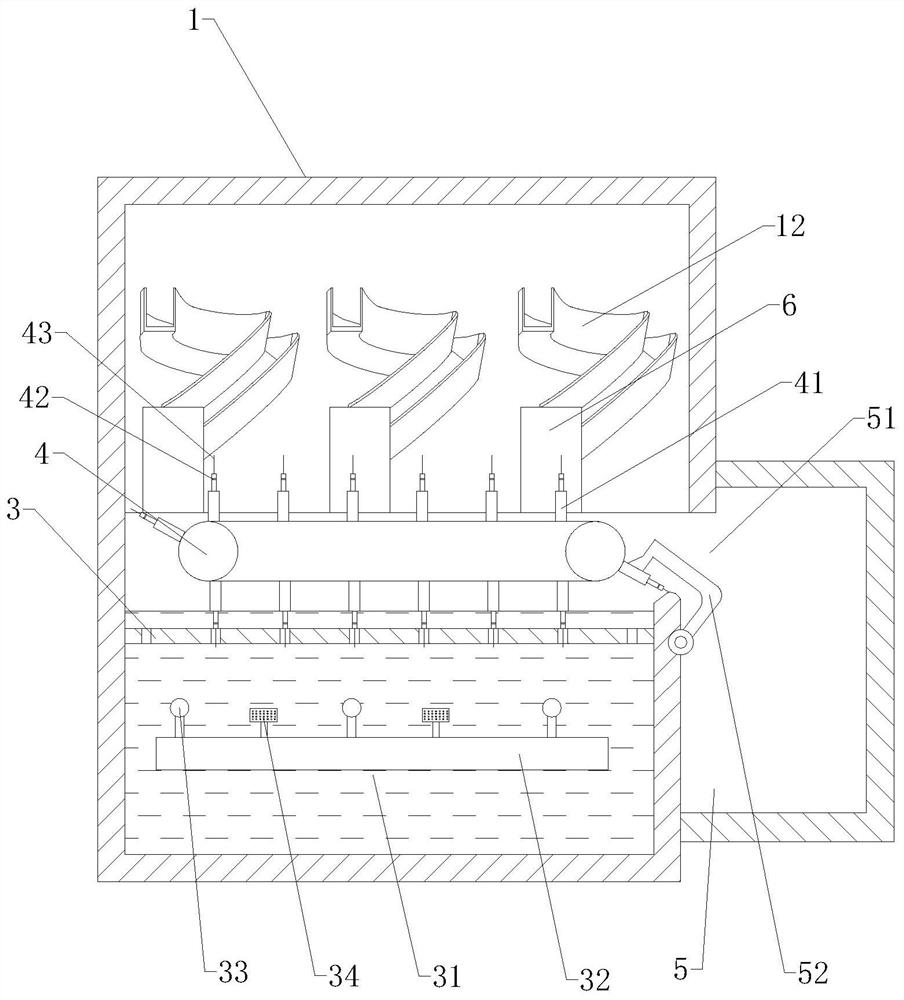

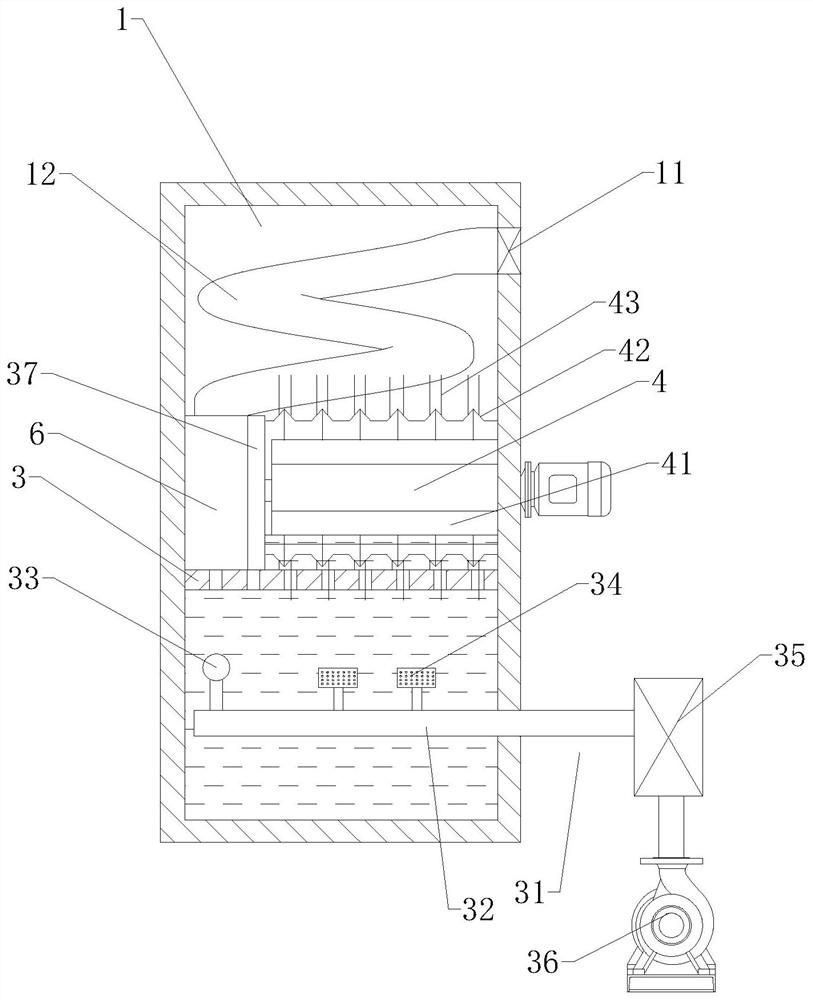

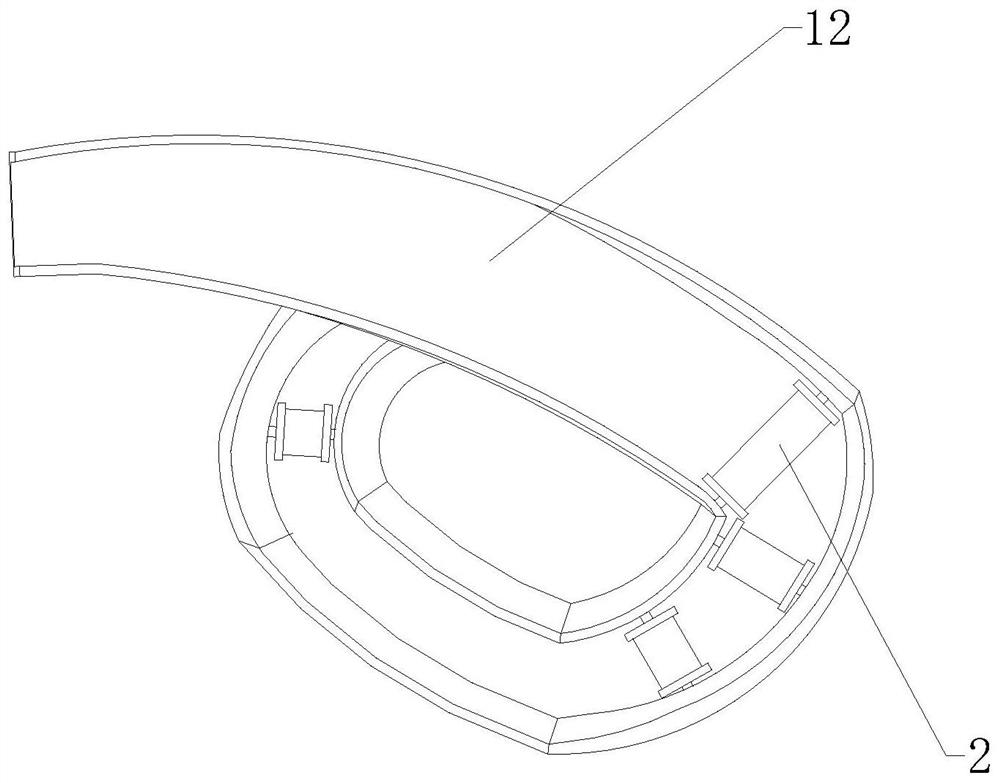

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0028] Example.

[0029] A method for dyeing silk / wool fibers, comprising the following steps:

[0030] S1. Pre-dry the silk / wool blended fibers, and then perform plasma pretreatment;

[0031] Through plasma treatment, tiny pits and longitudinal stripes appear on the surface of silk, improving the dyeing rate of silk; the scale layer on the surface of wool fiber is damaged and becomes soft, easy to absorb dyes, and the macromolecular chain on the surface of wool fiber is broken , form ions or free radicals, improve the hydrophilicity of the fiber surface, thereby improving the dyeing performance of wool, and subsequent dyeing at low temperature conditions, and improve the dyeing rate.

[0032] The pretreatment method of the plasma is as follows: the degree of vacuum is 50Pa, the power is 30w, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com