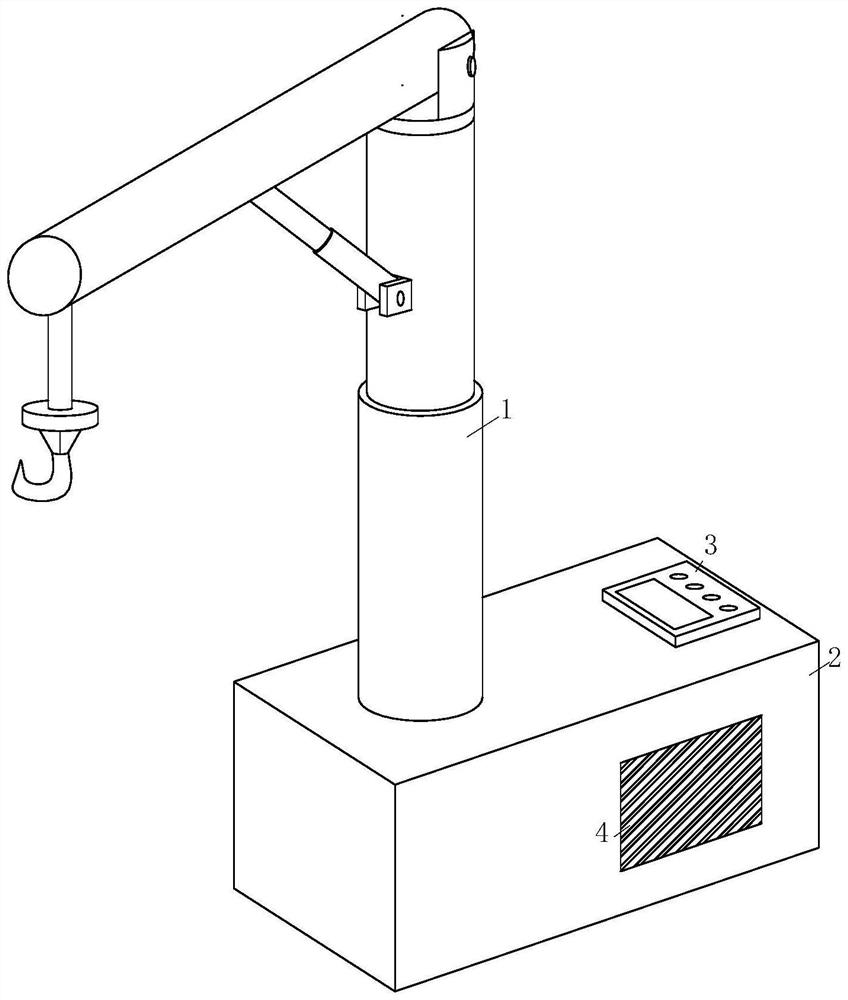

Hydraulic crane

A hydraulic crane and crane technology, which is applied in the direction of mechanical equipment, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problems of hydraulic oil temperature rise, hydraulic oil temperature cannot be lowered to a safe temperature, etc., to achieve increased The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

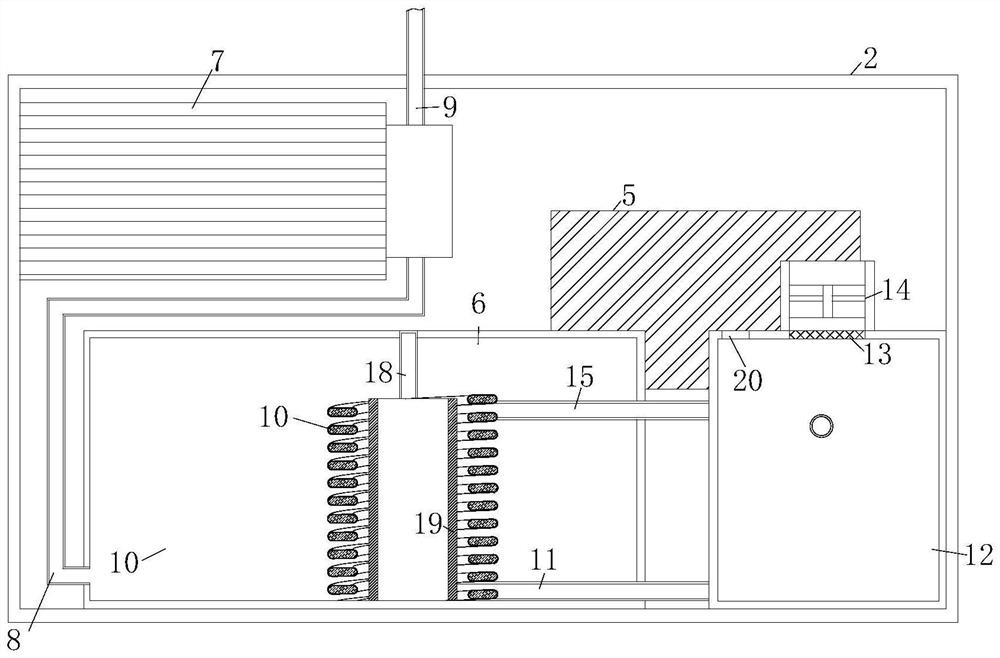

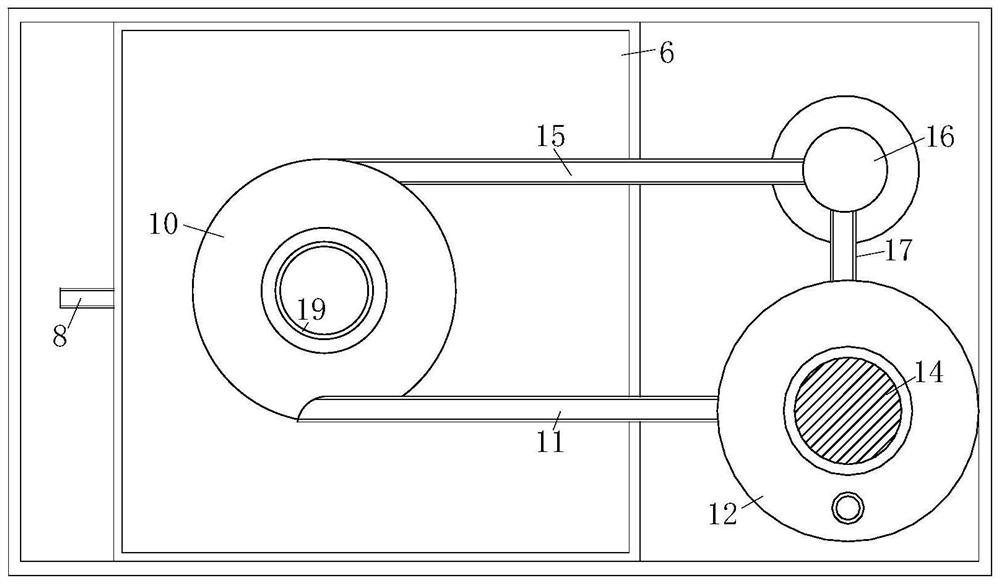

[0026] As an embodiment of the present invention, the inside of the spiral copper tube 10 is provided with a filter element 19, the filter element 19 is located directly under the oil inlet pipe 18, and the diameter of the filter element 19 is larger than the diameter of the oil inlet pipe 18. The core 19 can better filter impurities in the oil.

[0027] Working principle: The user starts the hydraulic pump 7 (model: A10VSO100) through the controller 3. First, the hydraulic oil enters the hydraulic oil tank 6 from the oil inlet pipe 18 and passes through the filter element 19 to filter out impurities. The hydraulic oil passes through the spiral copper pipe 10. The external spiral gap flows to the bottom of the hydraulic oil tank 6, and the hydraulic oil at the bottom of the hydraulic oil tank 6 is drawn out through the oil pumping pipe 8, and is pressurized by the hydraulic pump 7 and then fed into the oil delivery pipe 9, and the hydraulic oil is input into the interior of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com