Water anti-scaling method

A technology of ultrasonic and piezoelectric materials, applied in the new field of water anti-scaling, can solve the problems of low water utilization efficiency, change of water body composition, hidden safety hazards, etc., and achieve the effect of prolonging continuous working time, reducing hardness and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of heat exchange medium PTFE film coating

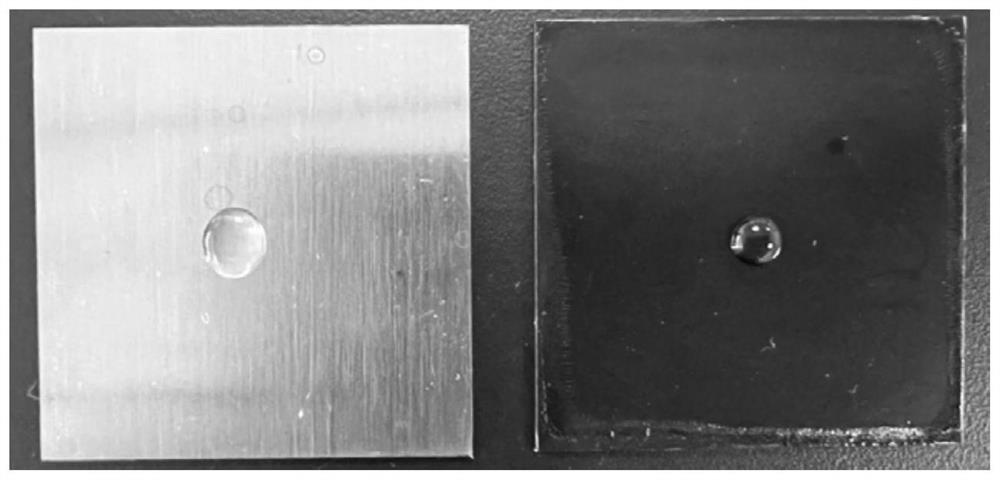

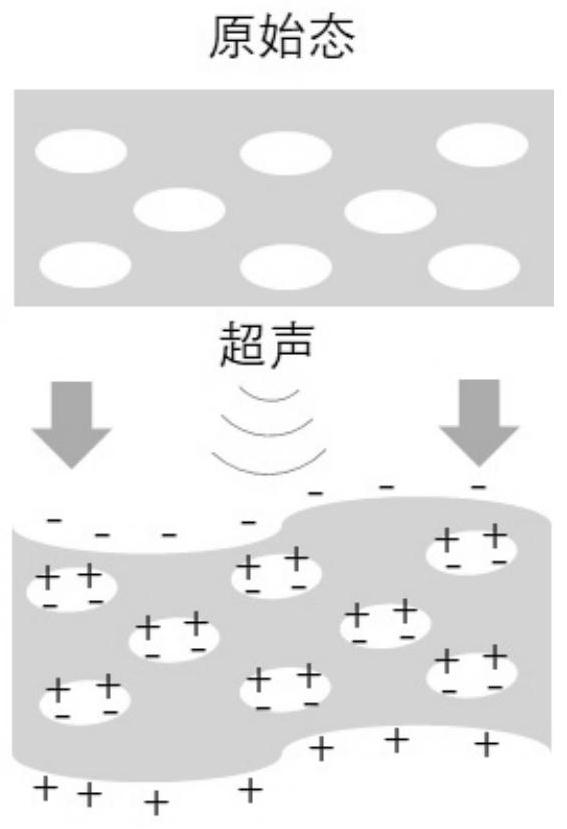

[0019] Weigh 25g of PTFE powder and add it to 475g of DMF solution, stir until completely dissolved, to obtain a 5% PTFE solution; evenly spread the coating solution on the stainless steel heat exchange medium, and dry at 350 °C to form a heat exchange medium electret PTFE film coating. like figure 1 Shown is a picture of the heat exchange medium electret PTFE film coating, and the contact angle of its water droplet is measured at the same time, which increases significantly. The heat exchange medium electret PTFE film coating was ultrasonically treated (ultrasonic cleaner: frequency 40KHz, power 100W) for 10 minutes, and then the piezoelectric coefficient of the coating film was measured, which was 290pC / N, much higher than the conventional piezoelectric Materials (The piezoelectric coefficient of conventional piezoelectric materials is (d33 ≈ 3–105 pC / N). We believe that: by applying ultrasonic waves ...

Embodiment 2

[0020] Example 2 Preparation of heat exchange medium PVDF film coating

[0021] Weigh 25g of PVDF powder into 475g of DMF solution, stir until completely dissolved, that is, a 5% PVDF solution; evenly spread the coating solution on the stainless steel heat exchange medium, and dry at 350 °C to form a heat exchange medium electret PTFE film coating. like figure 1 Shown is a picture of the heat exchange medium electret PVDF thin film coating, and the contact angle of its water droplets is measured at the same time, which increases significantly. The heat exchange medium electret PVDF film coating was ultrasonically treated (ultrasonic cleaner: frequency 40KHz, power 100W) for 10 minutes, and then the piezoelectric coefficient of the coating film was measured, which was 150pC / N, which was higher than that of conventional piezoelectric materials. (The piezoelectric coefficient of conventional piezoelectric materials is (d33 ≈ 3–105 pC / N). We believe that by applying ultrasonic w...

Embodiment 3

[0022] Example 3 Preparation of heat exchange medium PP film coating

[0023] Weigh 25g of PP powder and add it to 475g of DMF solution, stir until completely dissolved to obtain a 5% PP solution; apply the coating solution evenly to the stainless steel heat exchange medium, and dry at 350°C to form a heat exchange medium electret PP film coating. like figure 1 Shown is a picture of the heat exchange medium electret PP film coating, and the contact angle of its water droplets is measured at the same time, which increases significantly. The heat exchange medium electret PP film coating was ultrasonically treated (ultrasonic cleaner: frequency 40KHz, power 100W) for 10 minutes, and then the piezoelectric coefficient of the coating film was measured, which was 155pC / N, which was higher than that of conventional piezoelectric materials. (The piezoelectric coefficient of conventional piezoelectric materials is (d33 ≈ 3–105 pC / N). We believe that: by applying ultrasonic waves to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com