Suspension insulator automatic production line

A suspension insulator, automatic production technology, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problem of weak bonding of insulators, achieve firm bonding strength, enhance bonding strength, and save glue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

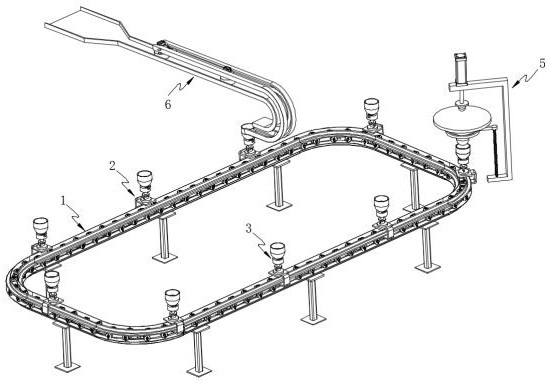

[0049] like figure 1 As shown, the present invention provides an automatic production line for suspension insulators, including:

[0050] The annular guide rail 1 and the moving plate 2 moving along the annular guide rail 1 are provided with a chain 11 in the annular guide rail 1 , and the moving plate 2 is mounted on the chain 11 .

[0051] The object-carrying part 3, the object-carrying part 3 installed on the sports board 2 is used for loading the iron cap;

[0052] The uniform gluing part 4, the uniform gluing part 4 evenly smears the glue on the inner surface wall of the iron cap;

[0053] Assembly part 5, assembly part 5 assembles the insulating part and the iron cap;

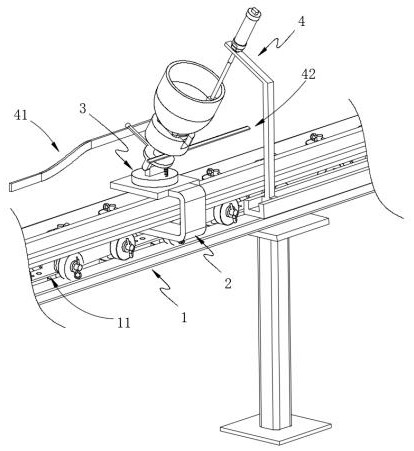

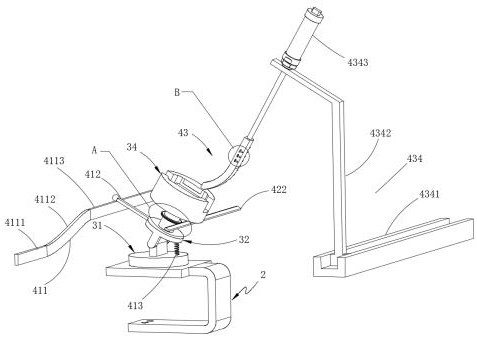

[0054] further, as figure 2 and image 3 As shown, the uniform gluing component 4 includes: an angle adjustment assembly 41, which adjusts the angle of the iron cap to apply glue on the inner surface wall of the iron cap; a rotating assembly 42; a gluing assembly 43, which is driven by the rotating a...

Embodiment 2

[0077] like Figure 7 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that the gluing assembly 43 in this embodiment further includes a pressing portion 436 .

[0078] Chinese Patent Application No. 201621027821.5 discloses an outdoor power system insulator. The inner wall of the iron cap in the insulator is provided with a plurality of annular grooves along the circumferential direction. The problem to be solved in this embodiment is how to better apply the adhesive in the annular groove;

[0079] preferably, as Figure 7 and Figure 10 As shown, the extrusion part 436 includes: a rotating shaft b4361; an endless belt b4362, which is sleeved on the outside of the rotating shaft b4361; a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com