Bamboo reinforced crop straw fiber-based fireproof door material and preparation method thereof

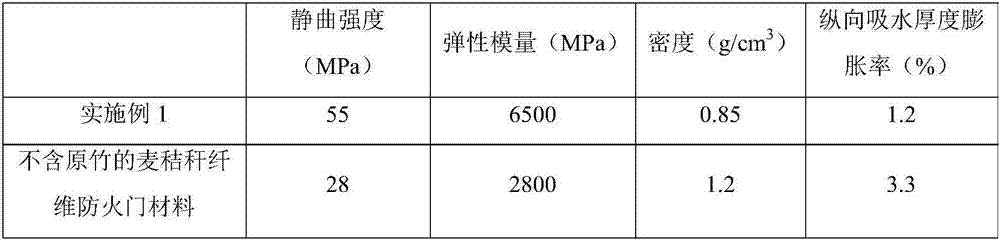

A technology of crop straw and fiber materials, which is applied in the pretreatment of molding materials, flat products, manufacturing tools, etc., and can solve the problems of high density and longitudinal water absorption expansion rate, low static bending strength and elastic modulus of straw fiber-based inorganic composite materials , limited application fields and other issues, to achieve the effects of improved physical and mechanical properties, increased static bending strength, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

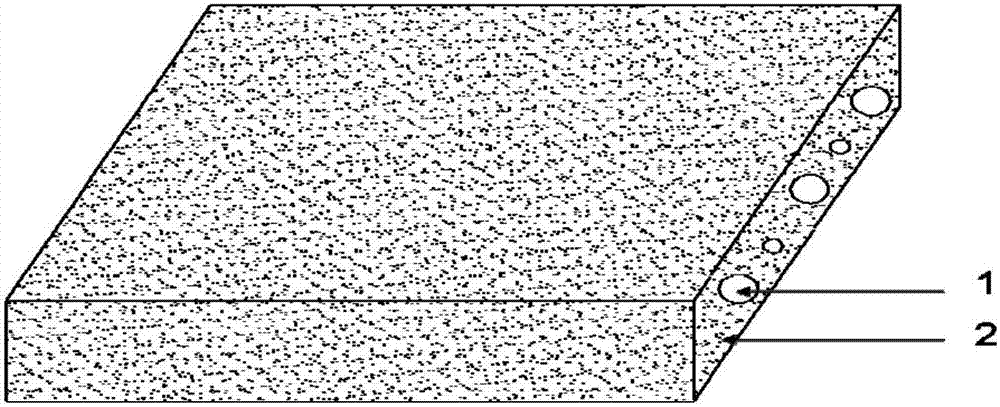

[0031] A kind of raw bamboo of the present invention strengthens crop straw fiber-based fireproof door material, is the composite material with wheat straw fiber material as matrix material, takes raw bamboo as reinforcing material; Its structure schematic diagram is as follows figure 1 As shown, it is provided with some original bamboos 1 in the middle of the crop straw fiber 2 (wheat straw fiber material in this embodiment), the thick and thin ends of adjacent original bamboos are placed upside down, the distance between adjacent original bamboos is 40mm, and the original bamboos The average diameter of the wheat straw fiber material is 20mm, and the wheat straw fiber material is formed by hot pressing after mixing uniformly the wheat straw fiber and the fireproof inorganic adhesive; the weight of the wheat straw fiber material accounts for 31 parts, and the weight of the inorganic adhesive accounts for 69 parts.

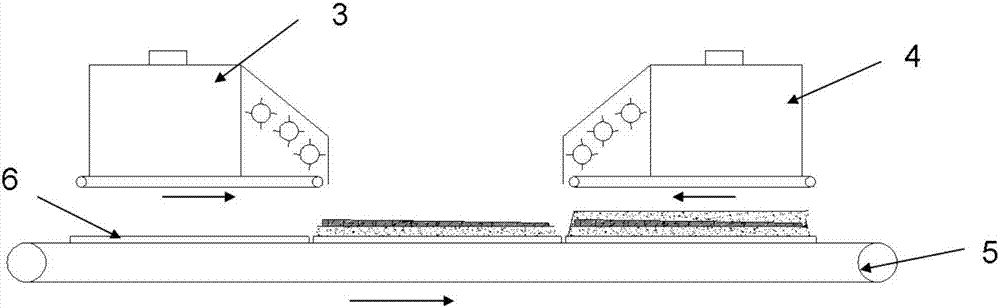

[0032] The raw bamboo reinforced crop straw fiber-based fire ...

Embodiment 2

[0044] A kind of raw bamboo reinforced crop straw fiber-based fire door material of the present invention is a composite material with straw fiber material as matrix material and raw bamboo as reinforcing material; its structural schematic diagram is as followsfigure 1 As shown, it is provided with some original bamboos 1 in the middle of the crop straw fibers 2 (in this embodiment, rice straw fiber material), the thick and thin ends of adjacent original bamboos are placed upside down, and the distance between adjacent original bamboos is 50mm. The average diameter of the straw fiber material is 30mm, and the straw fiber material is hot-pressed after mixing the straw fiber and the fireproof inorganic adhesive; the weight of the straw fiber material accounts for 28 parts, and the weight of the inorganic adhesive accounts for 72 parts.

[0045] The raw bamboo reinforced crop straw fiber-based fire door material of this embodiment comprises the following steps:

[0046] (1) Prepar...

Embodiment 3

[0057] A raw bamboo reinforced crop straw fiber-based fire door material of the present invention is a composite material with cotton stalk fiber material as a matrix material and raw bamboo as a reinforcing material; its structural schematic diagram is as follows figure 1 As shown, it is provided with several original bamboos 1 in the middle of the crop straw fiber 2 (cotton stalk fiber material in this embodiment), the thick and thin ends of adjacent original bamboos are placed upside down, and the distance between adjacent original bamboos is 70mm. The average diameter of the bamboo is 25mm, and the cotton stalk fiber material is formed by hot pressing after uniform mixing of cotton stalk fiber and fireproof inorganic adhesive; the weight of cotton stalk fiber material accounts for 45 parts, and the weight of inorganic adhesive accounts for 55 parts.

[0058] The raw bamboo reinforced crop straw fiber-based fire door material of this embodiment comprises the following steps:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com