Atomizer and related method of operation

An atomizer and rotary atomizer technology, applied in the field of atomizers, can solve the problems of cycle time loss, time prolongation of the coating system cycle time, impossible to clean the atomizer at the same time, etc., to eliminate cleaning and maintenance, The effect of omitting exhaust gas purification and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

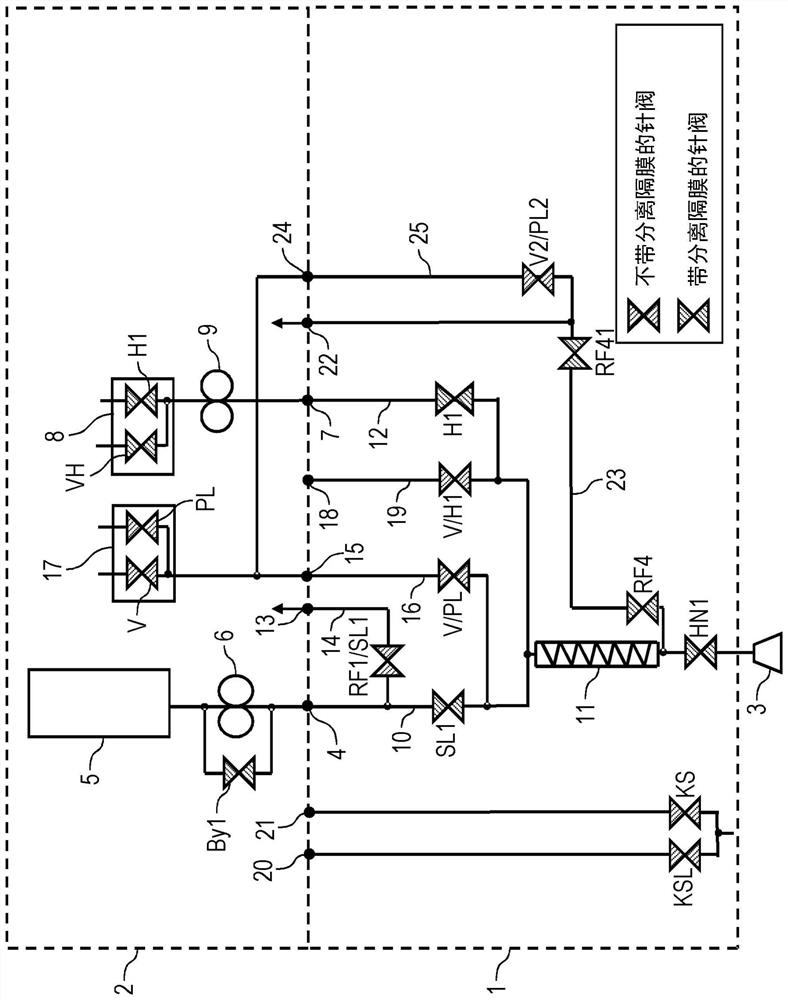

[0069] figure 1 A schematic diagram of a rotary atomizer 1 according to the present invention is shown, which is mounted on the robotic arm 2 of a conventional painting robot with a serial robotic kinematic mechanism. The robotic arm 2 is the distal robotic arm of the painting robot, which is also referred to as "arm 2" in common technical terms.

[0070] As is known from the prior art, the rotary atomizer 1 is used to apply multi-component coatings via a rotating bell cup 3 .

[0071] In order to supply the main paint, the rotary atomizer 1 has a main paint connection 4 which is supplied with the required main paint through a color changer 5 in the robot arm 2 .

[0072] A metering pump 6 is arranged between the color changer 5 and the main paint connection 4 of the rotary atomizer 1 to deliver the main paint in the desired paint flow. The metering pump 6 can be bypassed by a bypass valve By1 connected in parallel.

[0073] Furthermore, the rotary atomizer 1 has a hardener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com