Neodymium-iron-boron product cutting equipment

A cutting equipment, NdFeB technology, applied in the direction of shearing machine equipment, metal processing equipment, shearing devices, etc., can solve the problems of inability to reuse magnet waste and cutting fluid, increased work intensity, and reduced cutting efficiency. Achieve the effect of reducing the cumbersome feeding, avoiding accidental injury, reducing shaking and tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

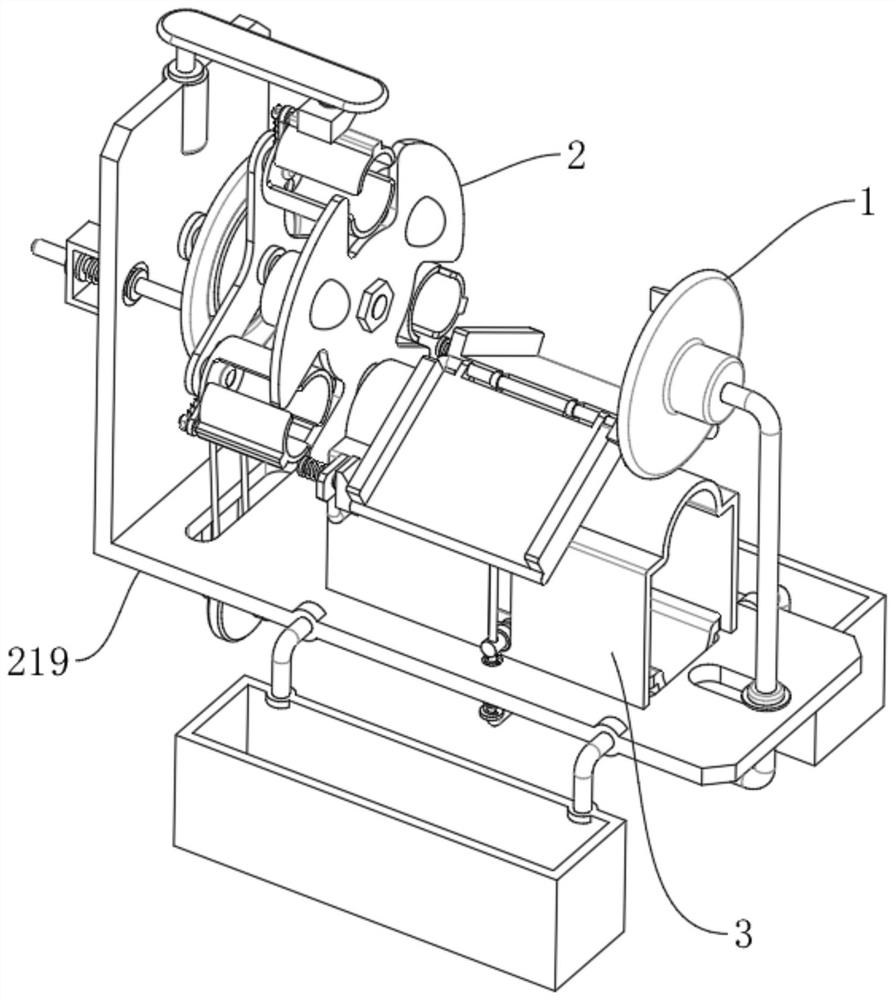

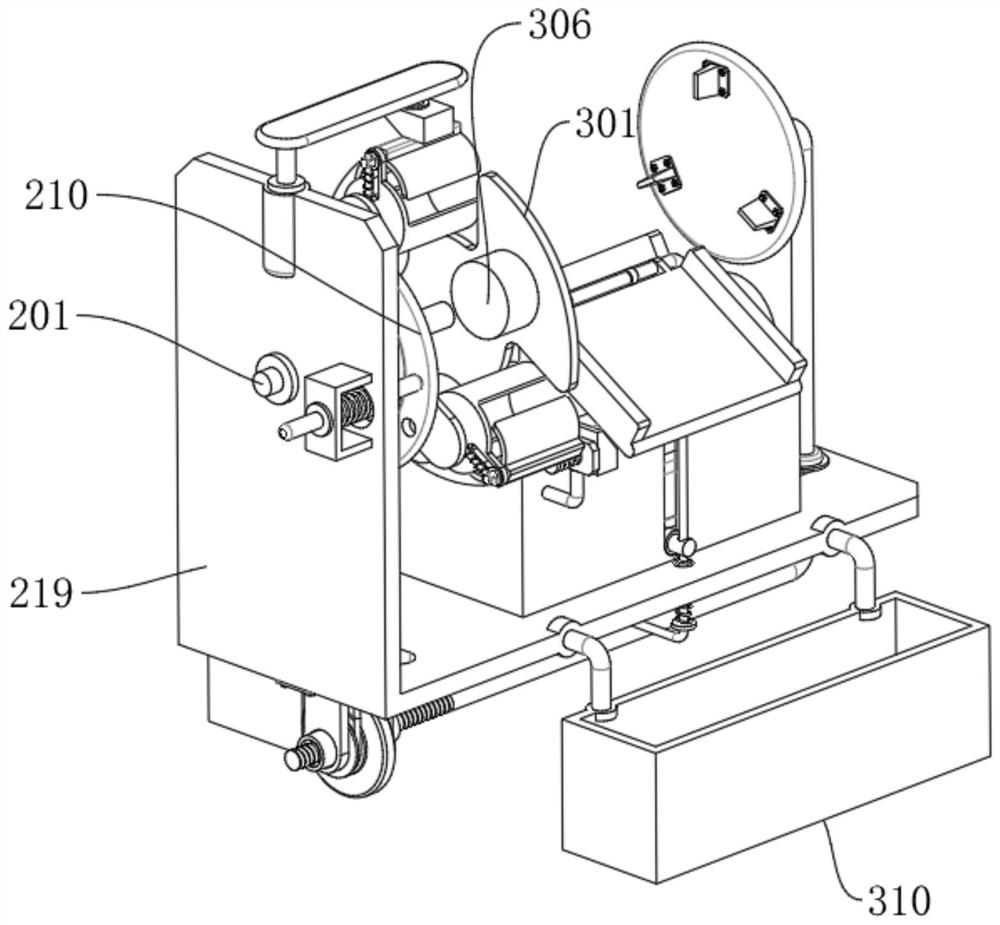

[0031] Please refer to Figure 1 to Figure 7As shown, a NdFeB product cutting equipment includes a cutting machine body 1, the left end of the cutting machine body 1 is provided with an automatic clamping and fixing replacement mechanism 2, and the right end of the automatic clamping and fixing replacement mechanism 2 is provided with an automatic feeding mechanism 3 , the automatic clamping and fixing replacement mechanism 2 includes a shaft 201, a triangular plate 202, a semi-cylinder 203, a short slot 204, a semi-circular upper cover 205, a power spring rod 206, an electromagnet 207, and a bending plate 219. The left end of the shaft 201 is rotatably connected with a Bending plate 219, a triangular plate 202 is fixedly connected to the right end of the shaft rod 201, one end of the triangular plate 202 is fixedly connected with a plurality of semi-cylinders 203, one end of the semi-cylinder 203 is provided with a short groove 204, and one end of the short groove 204 is slida...

Embodiment 2

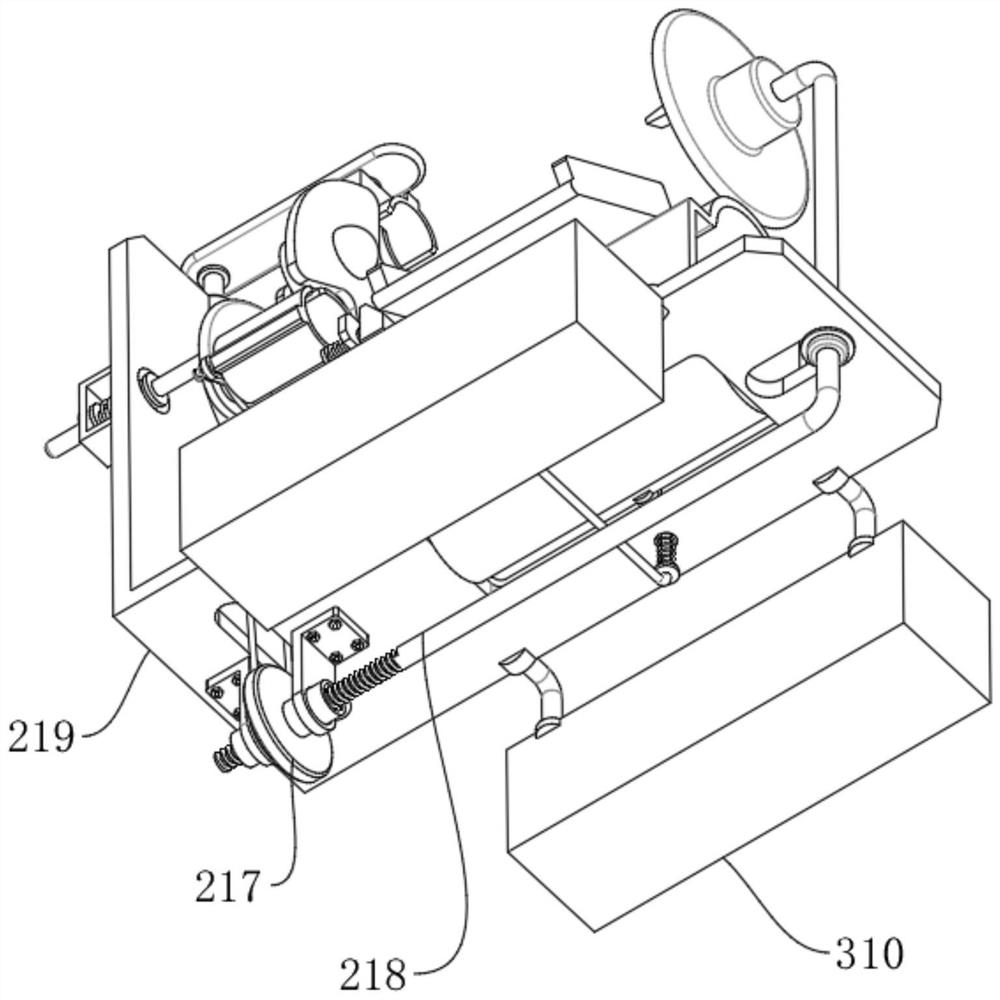

[0034] Please refer to Figure 5 and Figure 7 and Figure 8 As shown, the automatic feeding mechanism 3 includes a gap blocking plate 301, a storage bin 302, a semicircular feeding plate 303, and a curved spring rod 304. The right end of the shaft rod 201 is fixedly connected with a gap blocking plate 301, and the right end of the gap blocking plate 301 is provided There is a storage bin 302, the lower end of the storage bin 302 is fixedly connected to the upper end surface of the bending plate 219, the lower end of the storage bin 302 is slidably connected with a semicircular feeding plate 303, and the left and right ends of the semicircular feeding plate 303 are slidably connected with curved spring rods 304 , the lower end of the bending spring rod 304 is fixedly connected to the lower end of the bending plate 219, a plurality of balls 305 are evenly slidably connected to the gap blocking plate 301, and each ball 305 abuts a spring cylinder 306, and these spring cylinders...

Embodiment 3

[0038] Please refer to Figure 1 to Figure 8 As shown, a NdFeB product cutting equipment includes a cutting machine body 1, the left end of the cutting machine body 1 is provided with an automatic clamping and fixing replacement mechanism 2, and the right end of the automatic clamping and fixing replacement mechanism 2 is provided with an automatic feeding mechanism 3. The clamping and fixing replacement mechanism 2 includes a shaft rod 201, a triangular plate 202, a semi-cylinder 203, a short groove 204, a semi-circular upper cover 205, a power spring rod 206, an electromagnet 207, and a bending plate 219. The left end of the shaft rod 201 is rotatably connected with a bending The plate 219, the right end of the shaft 201 is fixedly connected with a triangular plate 202, one end of the triangular plate 202 is fixedly connected with a plurality of semi-cylinders 203, one end of the semi-cylindrical 203 is provided with a short groove 204, and one end of the short groove 204 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com