Manufacturing method of oversized polymer optical fiber panel

A technology of optical fiber panels and manufacturing methods, applied in the field of optical imaging, to achieve the effects of regular unit structure, stable internal structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

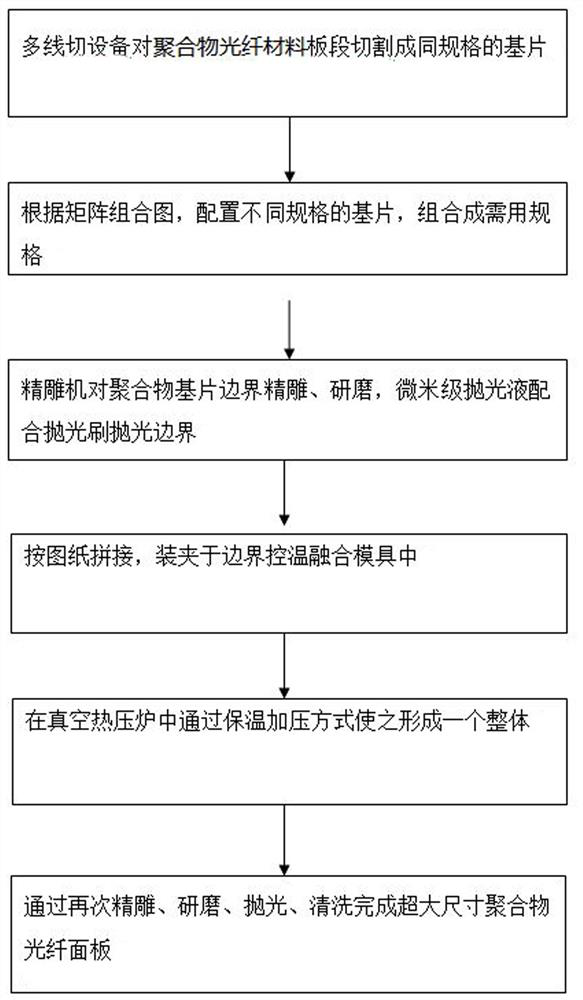

[0032] The specific content of the present invention is further described below:

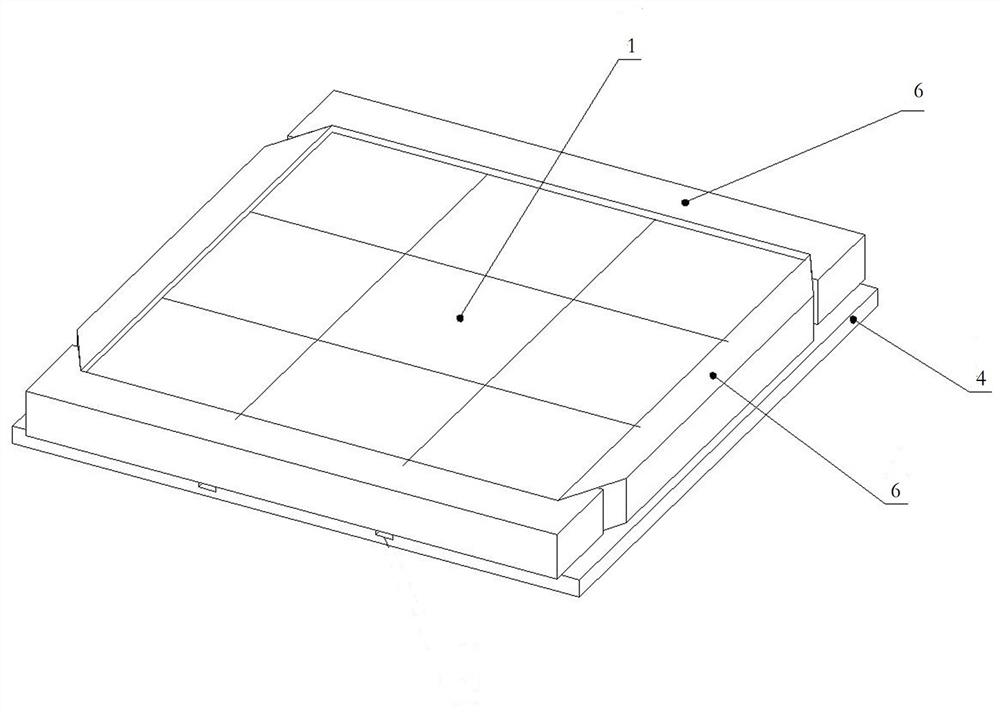

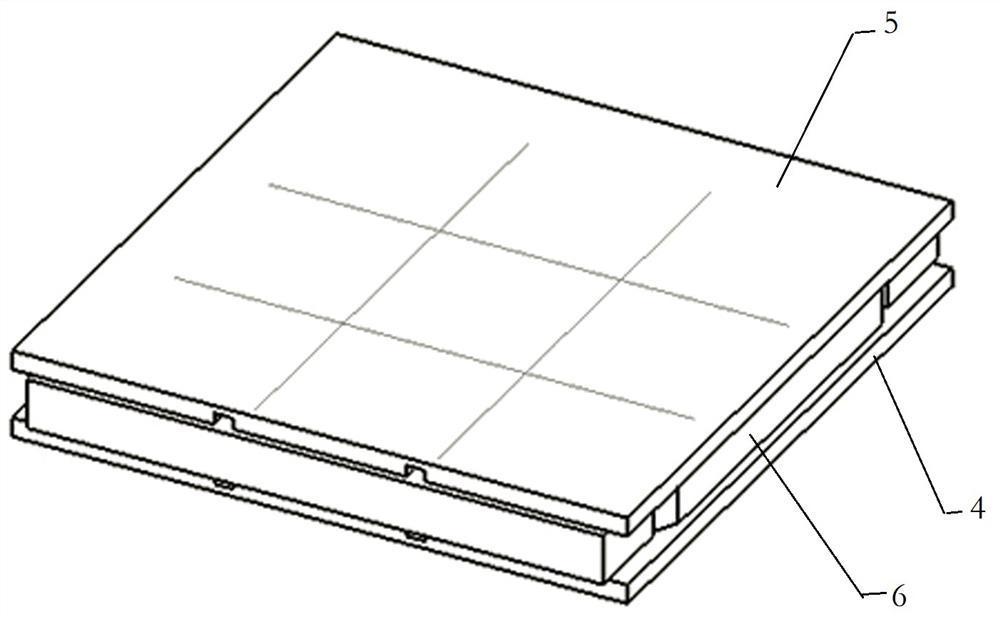

[0033] The manufacturing method of the super-sized polymer optical fiber panel of the present invention is to cut the raw material of the regular polygonal polymer panel into sheets, then finely carve, polish the boundary, and grind the plane to obtain a substrate, which is arranged in a matrix and installed in a matching mold, The method of external insulation and internal boundary heating is used to complete large-scale polymer blanks, which are sliced, ground, and polished to finally produce ultra-large-scale polymer optical fiber panels with low cost, high resolution, and wide application range.

[0034] The overall raw material of the specific polymer panel is a cube, and the interior is a polymer optical fiber monofilament arranged in an array. The polymer optical fiber monofilament includes a polymer core material and a polymer skin wrapping the polymer core material. The polymer core mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com