Precision etching aluminized film gravure online composite transfer printing method

A composite transfer and printing method technology, applied in the field of paper product packaging and printing, can solve the problems of increasing manufacturing costs and increasing production costs, and achieve the effect of simple verification means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

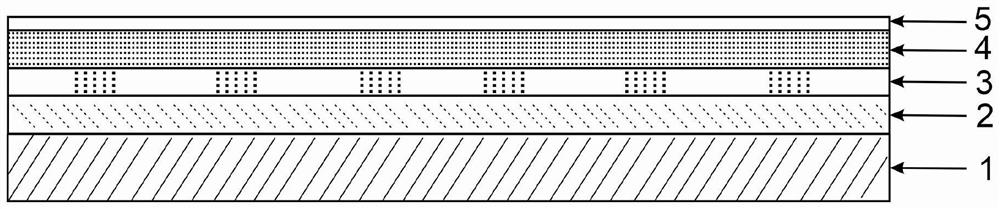

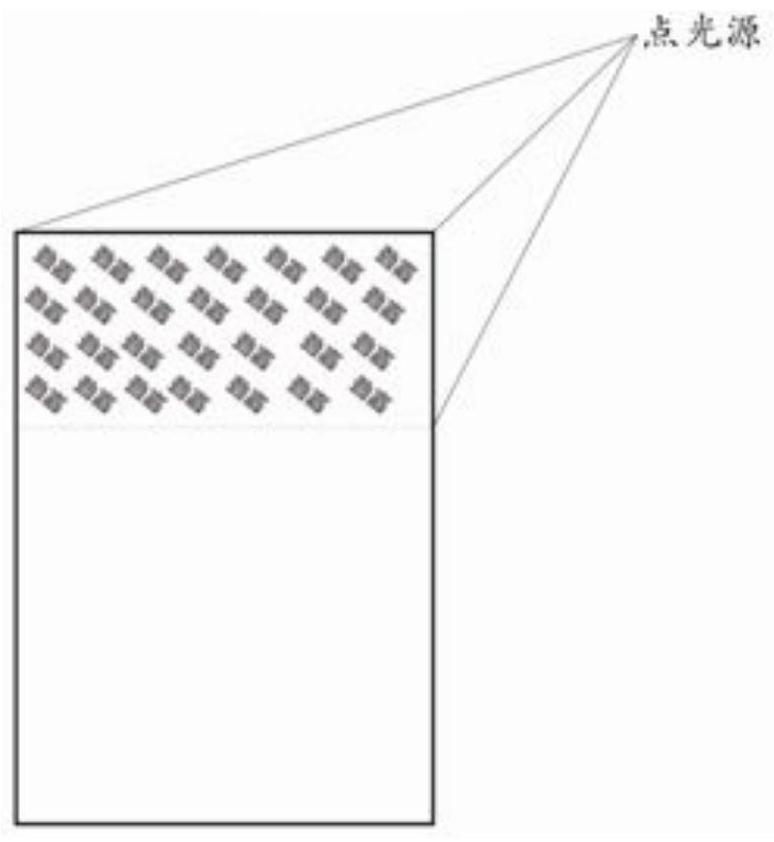

[0037] Example 1: as Figure 1-4Shown, a precision etching aluminized film gravure in-line composite transfer printing method. The method is as follows: when a conventional vacuum aluminized film production process is used to produce a vacuum aluminized film, high-temperature gaseous aluminum particles are deposited and cooled on the surface of the moving film substrate to form a continuous and bright metal aluminum layer, commonly known as vacuum aluminum plating. membrane. The invention pre-prints a layer of release resin ink pattern on the base film by prefabricating a precise etching gravure roll plate, so that when the high-temperature aluminum powder is deposited and cooled on the surface of the base material, a continuous and bright metal aluminum layer is obtained in the blank position. The metal aluminum layer at the position is repelled by the release resin, and its aluminized layer is only 45%-55% of the aluminized layer in the continuous blank position, so as to o...

Embodiment 2

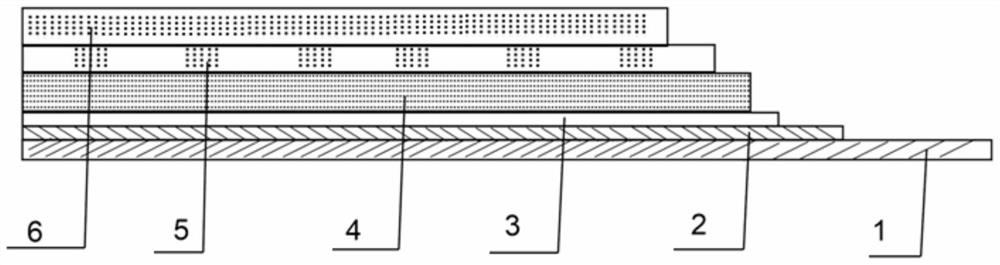

[0064] Example 2: as image 3 As shown in the figure, a precision etching invisible anti-counterfeiting material gravure connection printing structure includes a white cardboard layer 1, a transfer glue layer 2, a varnish protective layer 3, an aluminum plating layer 4, and an anti-counterfeiting graphic layer 5 from the bottom to the top. and printed graphic layer 6.

[0065] like Figure 4 As shown in the figure, a printing method of precision etching invisible anti-counterfeiting material gravure on-line printing structure, the method is: the anti-counterfeiting graphic information is made into an anti-counterfeiting gravure plate by a laser precision etching process, and the plate is used on a PET base. Film surface processing During the primer coating process, release resin ink printing is performed simultaneously, and then vacuum aluminum plating is performed to obtain a PET aluminized film with precision etched anti-counterfeiting information content. A new type of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com