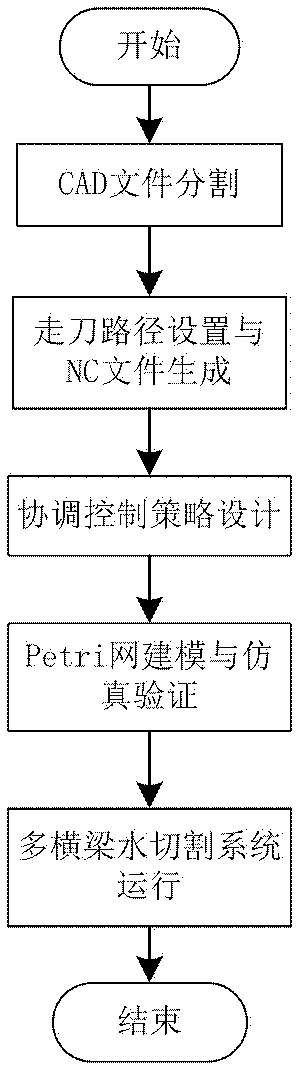

Online coordination control and Petri net verification method combined with water cutting process

A technology of coordinated control and verification methods, applied in program control, computer control, general control system, etc., can solve the problems of beam collision, long design cycle, high simulation cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiments of the present invention will be described in detail below, so as to more clearly show the stated and other objectives, features and advantages of the present invention.

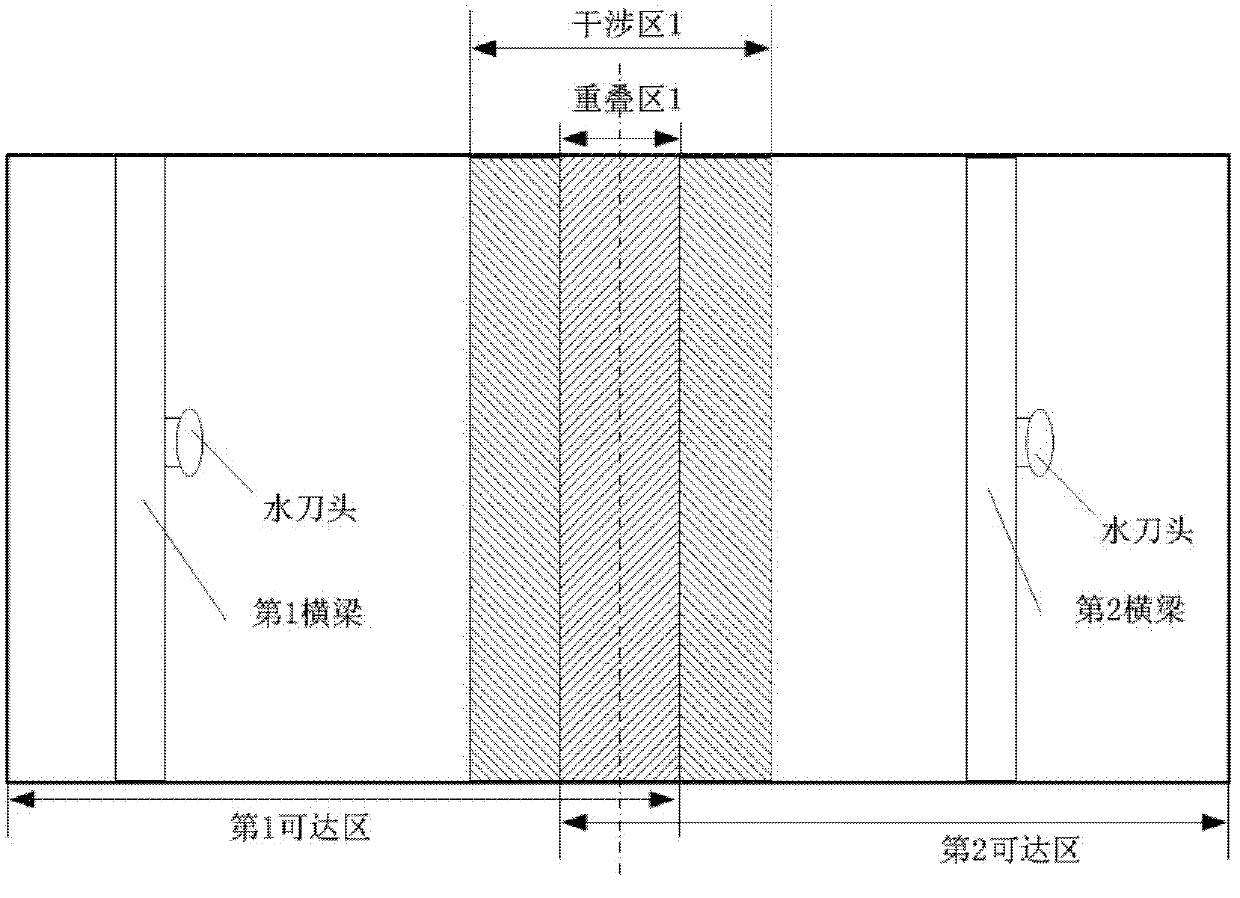

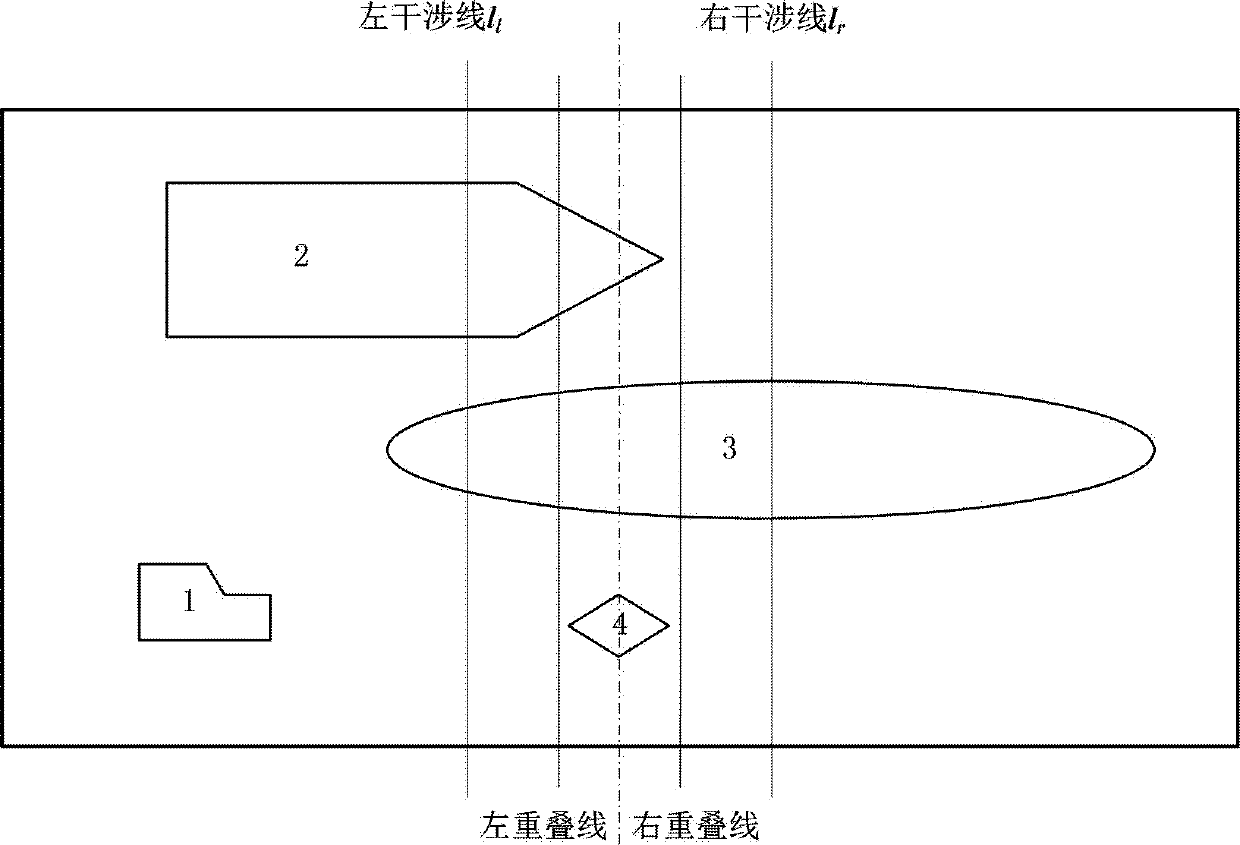

[0059] The invention refers to an online coordinated control method for the cutting process of a multi-beam water cutting system for large-sized workpieces. The large-sized workpiece here usually refers to the workpiece to be cut with a length of 3-12 meters, and also includes those workpieces with a length greater than 12 meters, but the width of the workpiece must be less than or equal to the width of the multi-beam system. Water jet cutting refers to the process of cutting workpieces by using the erosive force of high-pressure ultra-high-pressure water clusters. Each water cutting process is performed by a beam system (beam and water cutting head or nozzle installed on it), and the multi-beam water cutting system is a splicing combination of multiple water cutting beam system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com