Wax oil liquid phase hydrotreating method

A technology of hydrogenation treatment and liquid phase hydrogenation, which is applied in the field of oil refining and can solve the problems of high hydrogen consumption and hydrogen content requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

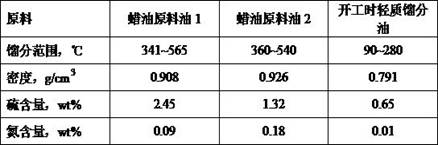

[0035] Below in conjunction with the examples, the process flow and the obtained effects of the wax oil liquid-phase hydrotreating method of the present invention are further described, but the following examples do not constitute a limitation to the method of the present invention.

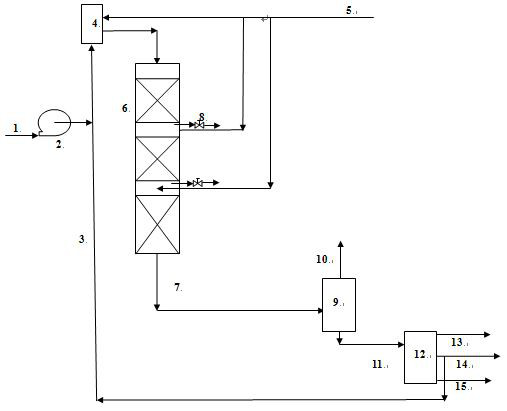

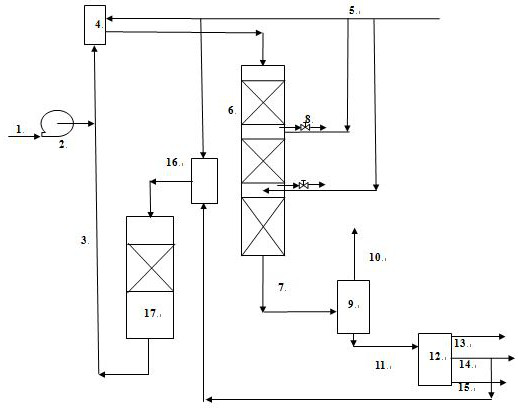

[0036] The specific embodiment of the liquid-phase hydrotreating method of wax oil of the present invention is as follows: the raw material oil 1 is mixed with the light cycle oil 3, the mixed material enters the hydrogen dissolving tank 4, and the hydrogen 5 is mixed with the mixed material in the hydrogen dissolving tank 4. Then it enters the reactor 6 and passes through the first catalyst bed. The effluent of the first catalyst bed is dissolved in hydrogen and passes through the second catalyst bed. The effluent of the second catalyst bed is dissolved into the hydrogen raw material and passed through the Three catalyst beds, the reaction effluent 7 of the third catalyst bed enters the low press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com