Silicon carbide epitaxial growth device and growth process method

A technology of epitaxial growth and silicon carbide, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as instability, difficulty in doping concentration, difficulty in meeting the requirements of high-quality MOSFET power devices, etc., and achieve reduction Edge effect, effect of uniform doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The above scheme will be further described below in conjunction with specific embodiments. It should be understood that these examples are intended to illustrate the present application and not to limit the scope of the present application. The implementation conditions adopted in the examples can be further adjusted such as the conditions of specific manufacturers, and the unremarked implementation conditions are usually the conditions in routine experiments.

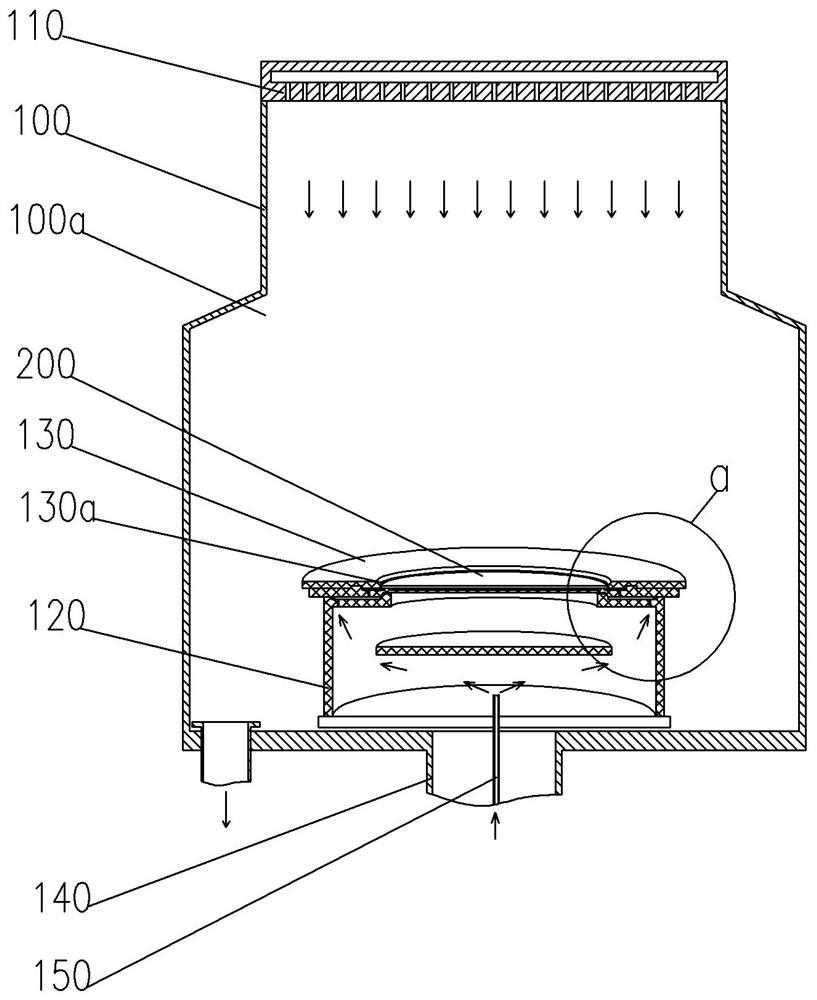

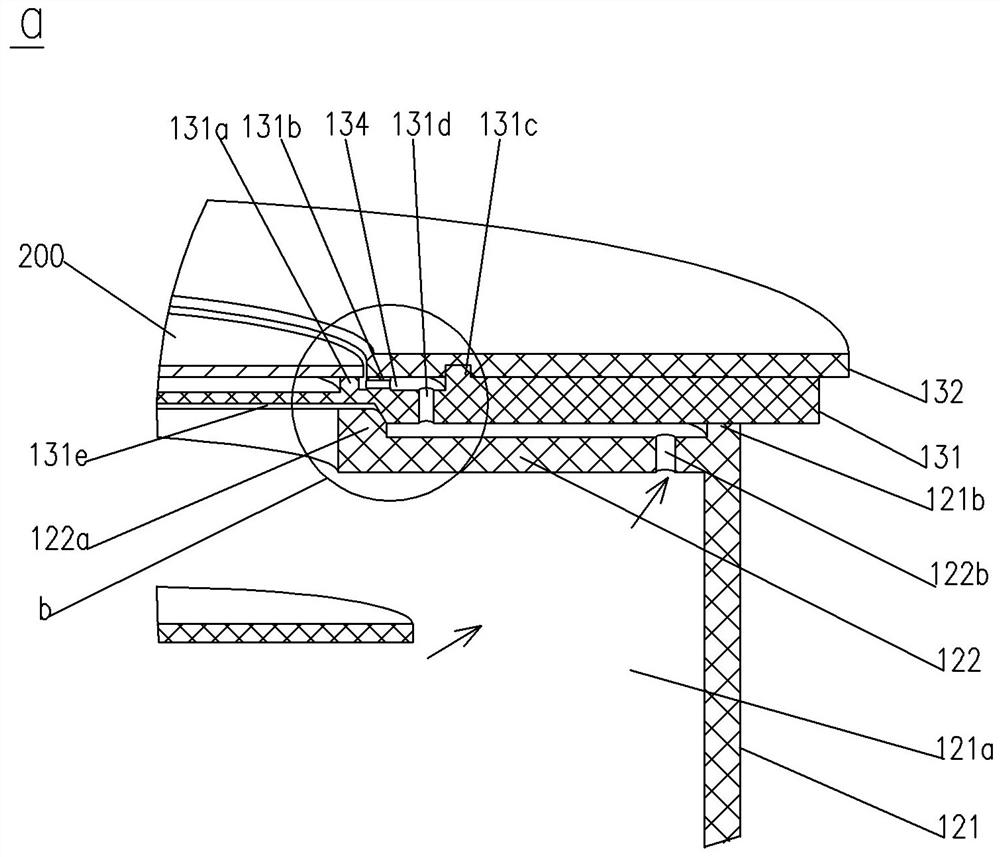

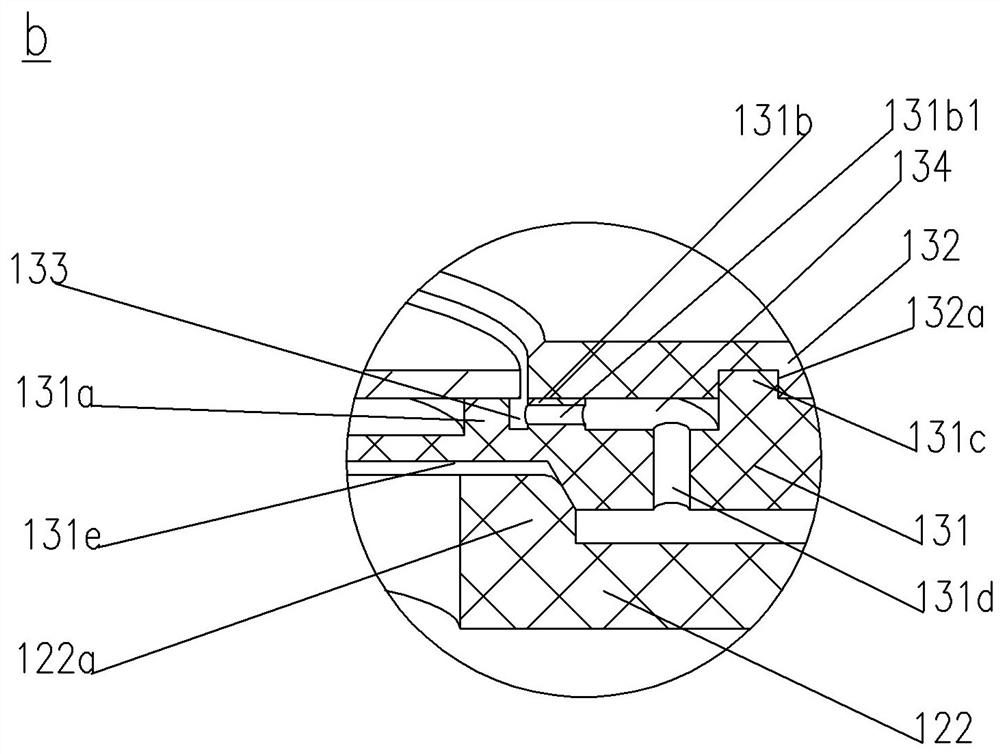

[0040] The present application provides a silicon carbide epitaxial growth device and a growth process method. The silicon carbide epitaxial growth device (hereinafter referred to as the growth device) includes: a reaction module and a rotating tray assembly, the reaction module is provided with a reaction chamber, the rotating tray assembly is arranged at the bottom of the reaction chamber, and the rotating tray assembly includes: a graphite tray and a rotating support The graphite tray is provided with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com