Milk tea making equipment and milk tea making method

A production method and technology of milk tea, applied in beverage preparation devices, coin-operated equipment for controlling the distribution of fluid/granular materials from containers, coin-operated equipment for distributing discrete items, etc., can solve the problem of difficult cleaning and affecting taste , health problems and other issues, to achieve the effect of improving the degree of automation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

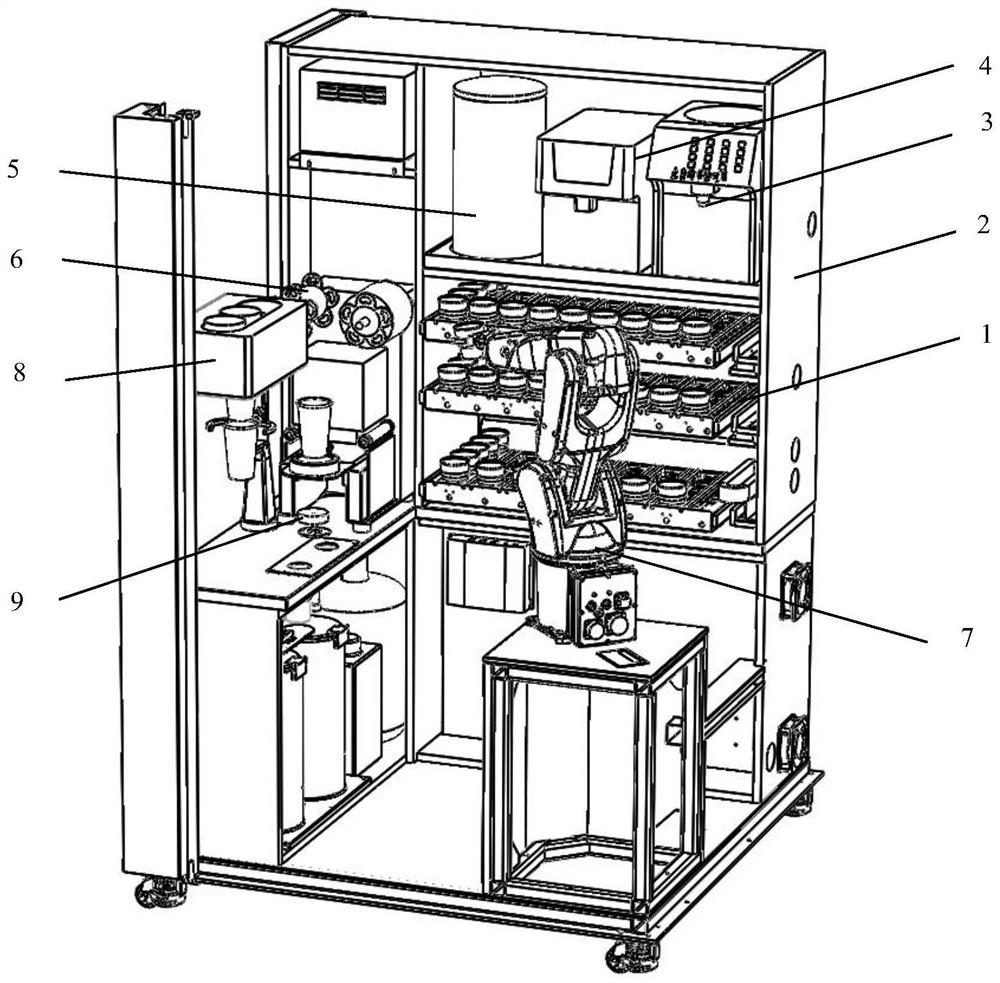

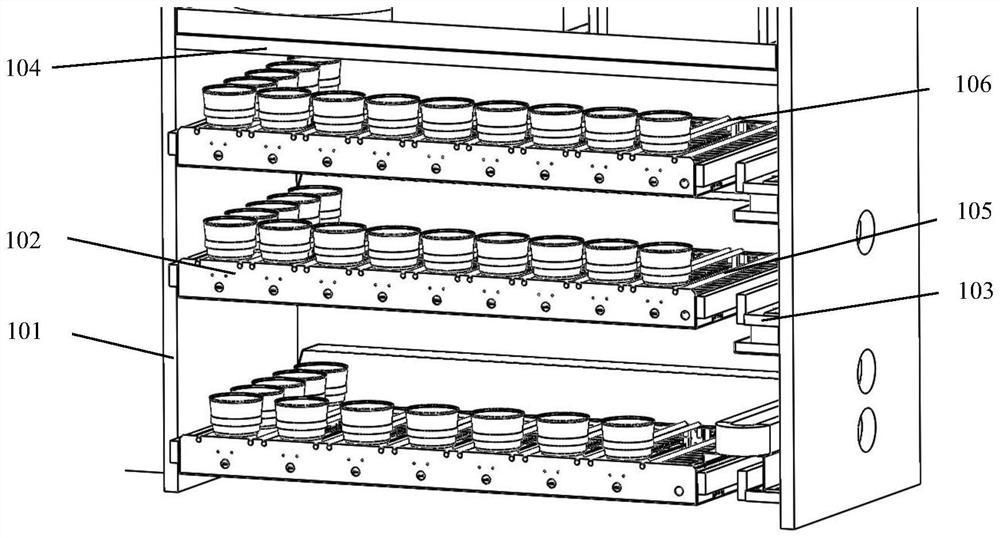

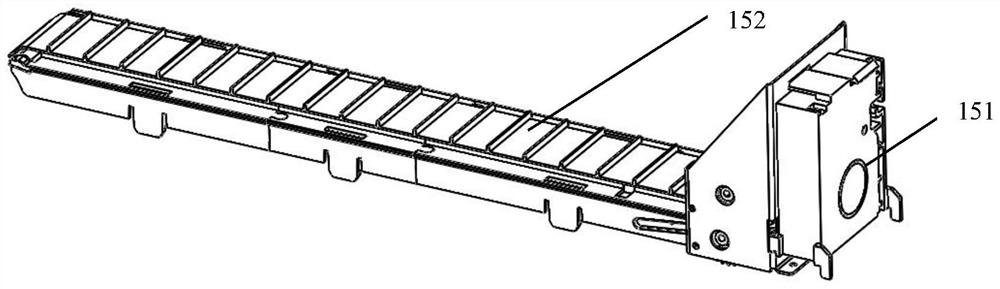

[0034] like Figure 1-Figure 13 As shown in the figure, a milk tea making equipment includes a cargo passage assembly 1, a joint robot 7, an automatic cup sealing mechanism 6, an automatic cup dropping mechanism 8, a liquid feeding mechanism 5, an automatic sugar supplying machine 4 and an automatic ice making machine 3, The cargo entry channel assembly 1, the joint robot 7, the automatic cup sealing mechanism 6, the automatic cup drop mechanism 8 and the liquid feeding mechanism 5 are all arranged inside the main frame 2, which is a frame structure and is constructed of profiles; the main frame 2 It is divided into upper and lower layers. The loading lane assembly 1, the joint robot 7, the automatic cup sealing mechanism 6, and the automatic cup dropping mechanism 8 are arranged on the upper layer of the main frame 2, and the control system is integrated in the control cabinet and arranged on the lower layer of the main frame 2. , thereby reducing the footprint of the milk te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com