On-line catalyst loading and unloading method and system for fluidized bed residual oil hydrogenation process

A catalyst and bed residual oil technology, which is applied in chemical instruments and methods, petroleum industry, hydrocarbon oil cracking, etc. Reliable cycle operation and the effect of reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

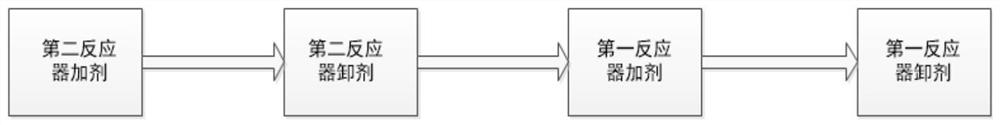

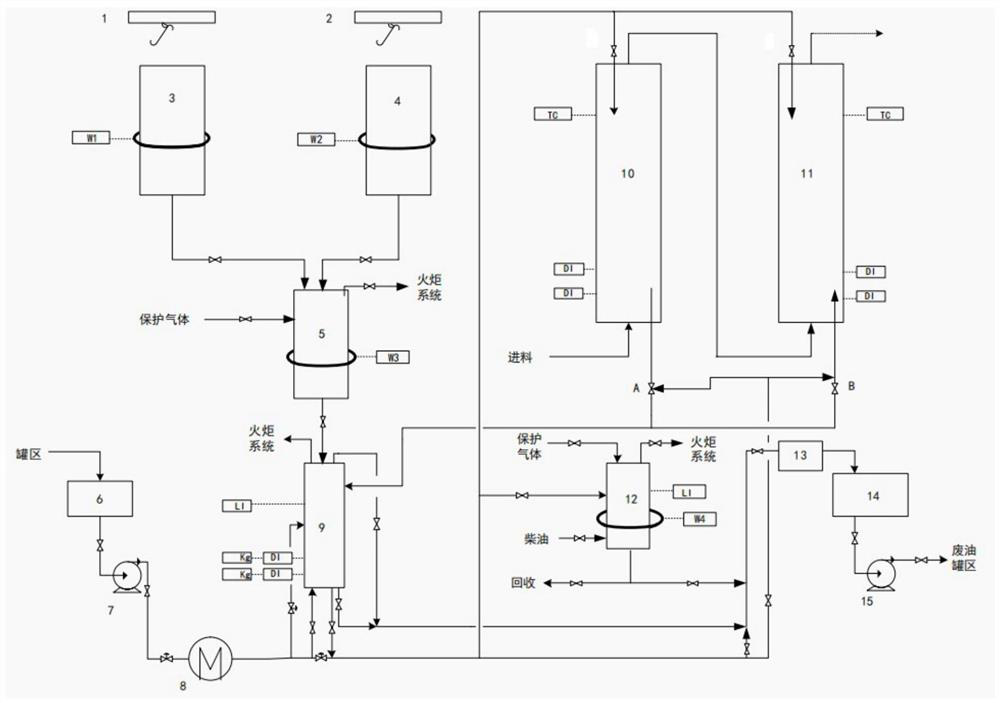

[0067] figure 1 The catalyst online loading and unloading system of this embodiment is shown, and the system is used for unloading the catalyst used in the first reactor 10 and the second reactor 11 in the ebullated bed residue hydrogenation process, and sending it to the third reactor. A new catalyst is added to the second reactor 11 to ensure the activity of the catalyst.

[0068] like figure 1 As shown, the catalyst online loading and unloading system of this embodiment includes:

[0069] The first reactor 10, the second reactor 11, the first lifting device 1, the second lifting device 2, the new catalyst storage tank 3, the regenerated catalyst storage tank 4, the catalyst metering tank 5, the loading and unloading tank 9, the spent catalyst tank 12 And transport oil storage tank 6.

[0070] The first reactor 10 and the second reactor 11 are used as reaction vessels for crude oil such as heavy crude oil residue. In the process of processing the raw material oil such as...

Embodiment 2

[0091] Adopt the system online loading and unloading catalyst of embodiment 1, and concrete steps are as follows:

[0092] Open the on-off valve, the transfer oil pump 7 and the transfer oil heater 8 on the transfer oil inlet pipe between the transfer oil storage tank 6 and the second end of the loading and unloading tank 9 . The delivery oil from the delivery oil storage tank 6 enters the delivery oil heater 8 under the pumping action of the delivery oil pump 7 , and the temperature rises to 350° C. after being heated in the delivery oil heater 8 . The heated delivery oil enters the loading and unloading tank 9 from the second end under the pumping action of the transporting oil pump 7, so that the ambient temperature in the loading and unloading tank 9 rises to above the minimum boost temperature (ie, the MPT temperature). Close the switch valve on the delivery oil inlet pipe between the delivery oil heater 8 and the second end of the loading and unloading tank 9 . The tran...

Embodiment 3

[0123] Except for the following conditions, the catalyst was loaded and unloaded online in the same manner as in Example 2:

[0124] The flow rate of conveying oil is 15m 3 / h, the temperature of the delivered oil is 360°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com