Locking device and engineering machinery vehicle

A locking device and locking hook technology, applied in vehicle parts, electric vehicles, transportation and packaging, etc., can solve the problems of easy operator fatigue, increase in the cost of the whole machine, space requirements for the whole machine, and difficulty in on-site operation, etc. Avoiding the increase of cost and installation space, alleviating the anxiety of battery life, quick and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

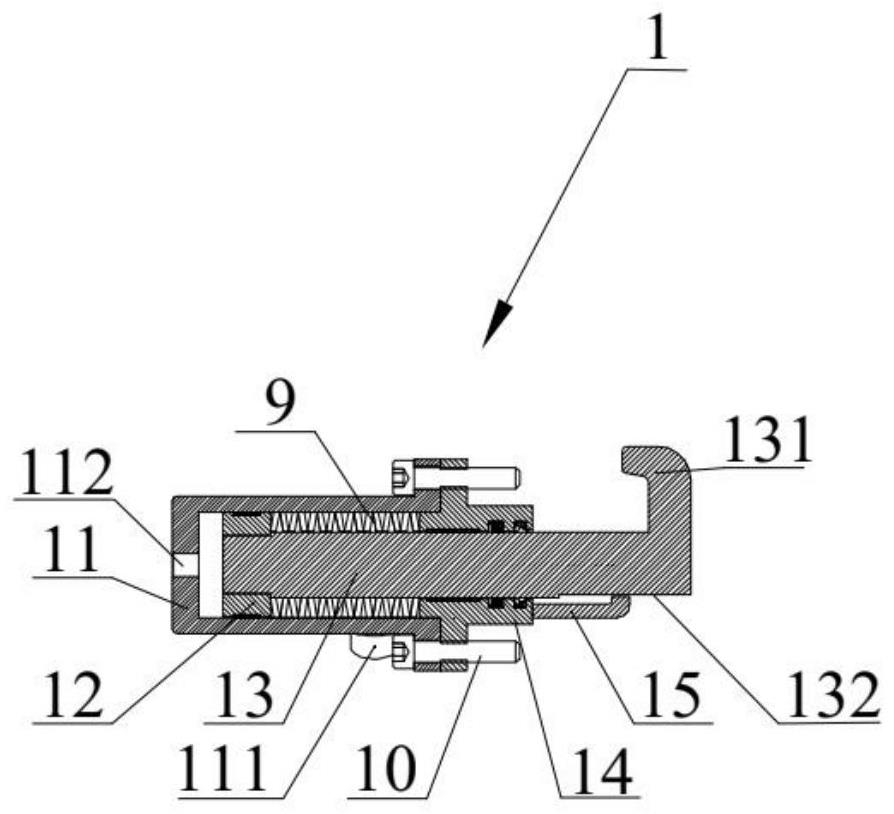

[0044] like figure 1 As shown, this embodiment provides a locking device for locking a first mounting piece and a second mounting piece that cooperate with each other, the locking device includes a hydraulic cylinder 1, and the hydraulic cylinder 1 includes a cylinder block 11 and a piston rod 13. The piston rod 13 is slidably installed in the cylinder 11 through the piston 12, and the end of the piston rod 13 away from the piston 12 is provided with a locking hook 131; the cylinder 11 is fixed on the first mounting piece, the first mounting piece and the second mounting piece After the fitting is located between the cylinder 11 and the locking hook 131, the piston rod 13 is retracted, and the locking hook 131 can abut with the second mounting piece to lock the first mounting piece and the second mounting piece; the piston rod 13 When extended, the locking hook 131 comes out of contact with the second mounting member, so that the first mounting member and the second mounting m...

Embodiment 2

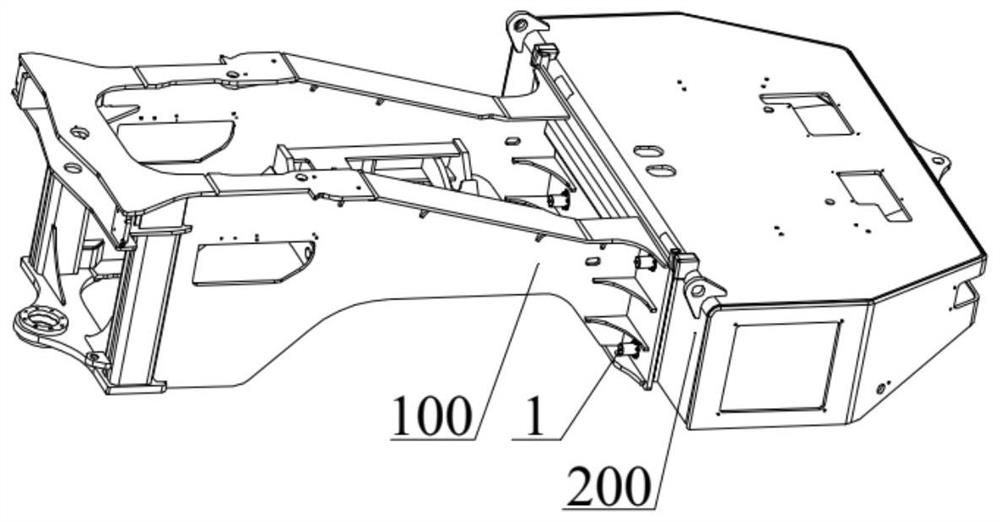

[0066] like image 3 As shown, this embodiment provides a construction machinery vehicle, including a vehicle frame 100 and a battery pack mounting frame 200 , and the vehicle frame 100 and the battery pack mounting frame 200 are locked by the locking device provided in the first embodiment. Among the vehicle frame 100 and the battery pack mounting frame 200 , one of them is a first mounting member, and the other is a second mounting member. That is, the cylinder block 11 of the hydraulic cylinder 1 of the locking device may be fixed on the vehicle frame 100 or may be fixed on the battery pack mounting frame 200 . The battery pack that provides power for the construction machinery vehicle is arranged in the battery pack mounting frame 200 .

[0067] Exemplarily, the cylinder block 11 of the locking device is fixed on the vehicle frame 100 by fastening bolts 10 .

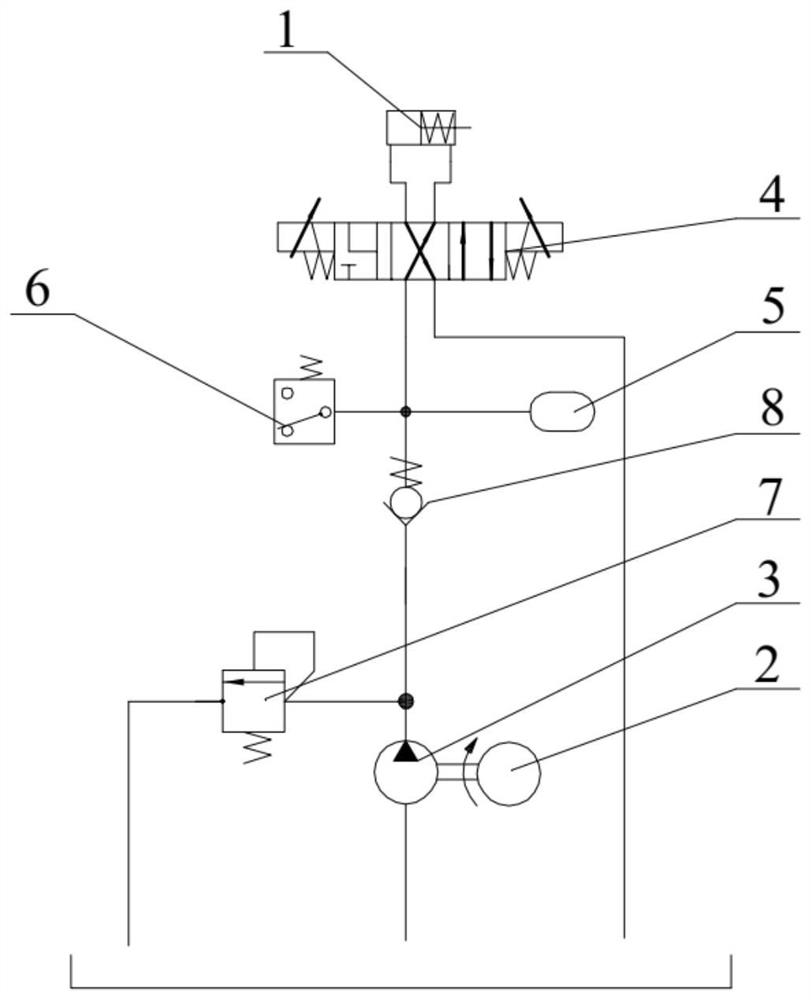

[0068] The motor 2 is a DC motor, which is used to drive the hydraulic pump 3 to work. The motor 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com