Graphene metal-based composite material and preparation method thereof

A composite material and graphene technology, applied in the direction of metal processing equipment, non-metallic elements, chemical instruments and methods, etc., can solve the problems of powerless heat dissipation density electronic devices, low heat dissipation efficiency, etc., and achieve the effect of enhancing heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a preparation method of a graphene metal-based composite material, specifically a preparation method of a molecular-level treated graphene-copper-based composite material, comprising the following steps:

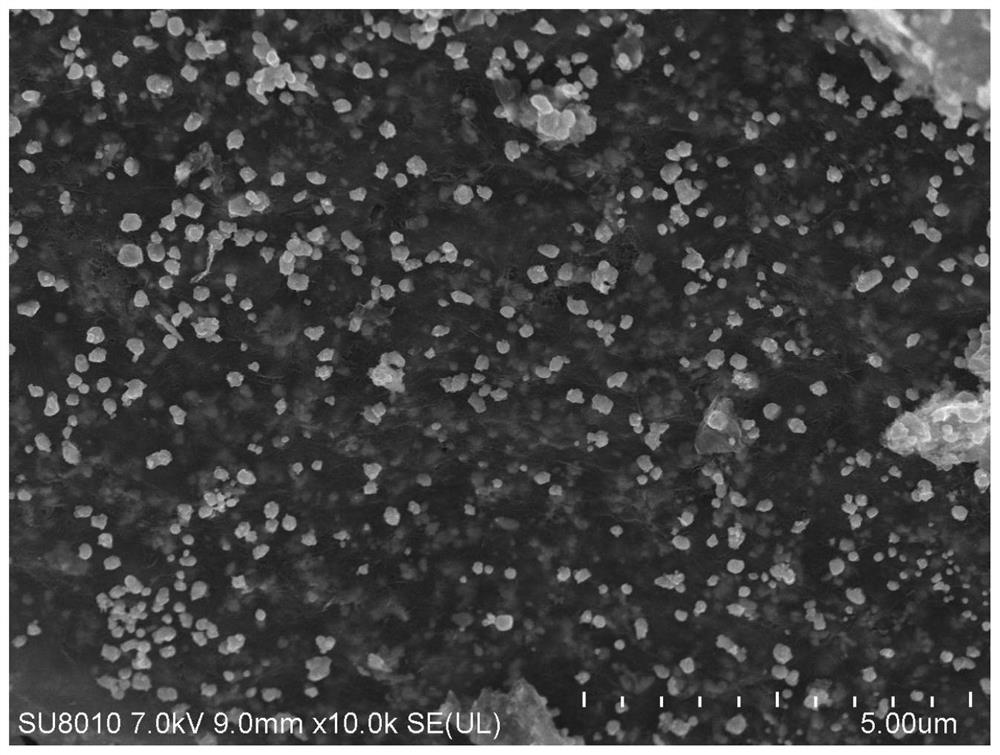

[0034] Adding graphene to CuSO 4 In the solution, ultrasonically vibrate for 10min to disperse evenly, then insert the positive and negative electrodes into the mixed solution, control the voltage of the positive and negative electrodes, reverse the electrodes every 2min, and reverse 6 times, and finally scrape the mixture on the electrodes to obtain metallized graphite alkene, its SEM microstructure see figure 1 .

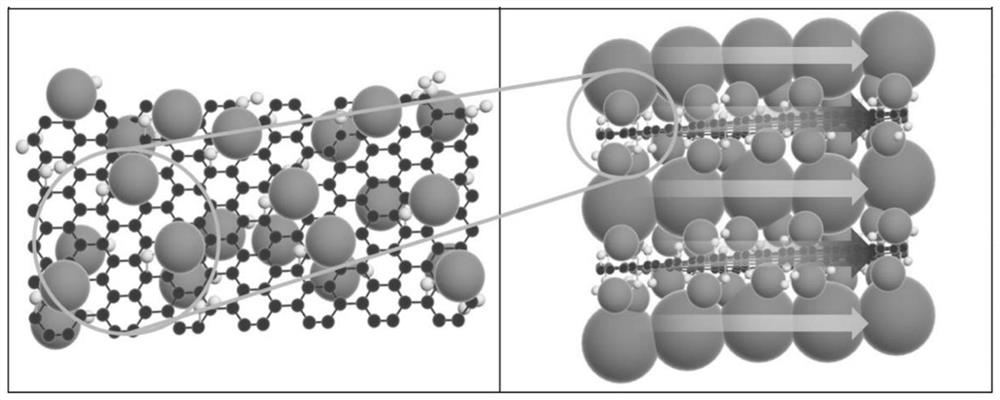

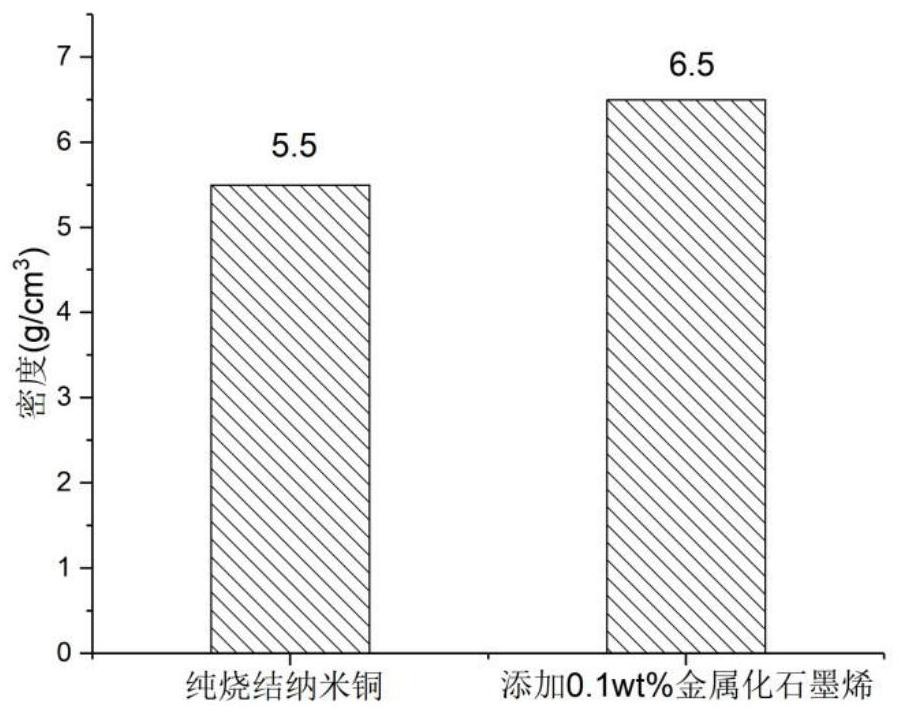

[0035] The metallized graphene, nano-copper powder and organic solvent are mixed to obtain nano-copper paste, which is finally sintered in a hot pressing sintering furnace, the sintering temperature is 300° C. and the pressure is 5 MPa to obtain the graphene metallized composite material.

[0036] CuSO in this example 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com