Fabricated pile cap for composite foundation

A composite foundation, prefabricated technology, applied in sheet pile walls, infrastructure engineering, manufacturing tools, etc., can solve the problems of thinning thickness, tensile crack damage, easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

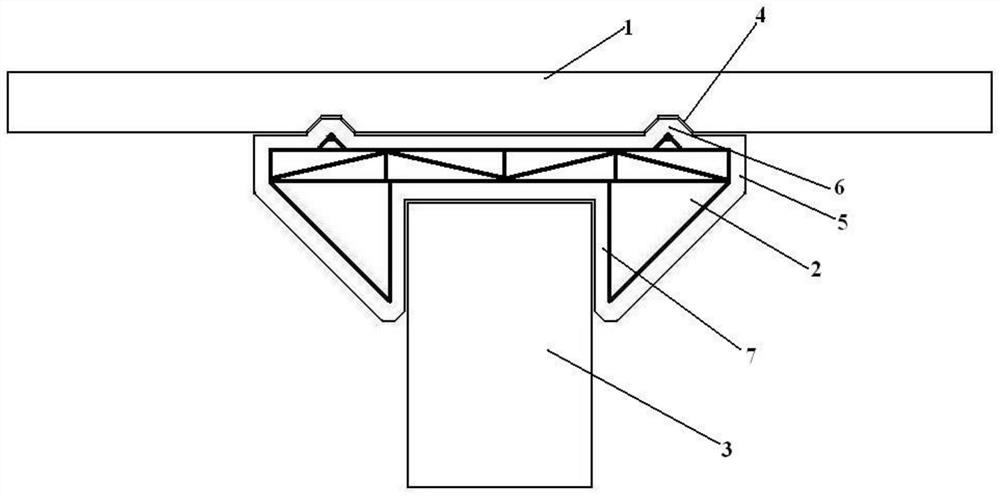

[0049] like figure 1 , 2 As shown in the figure, a prefabricated pile cap for composite foundation is prefabricated, the pile cap includes a top plate 1 and a fixing kit 2 supported on the lower side of the top plate 1, and the fixing kit 2 is used to be sleeved on the upper end surface of the pipe pile 3 In this embodiment, a ring-shaped groove 4 is provided on the lower surface of the top plate 1, and the groove walls of the ring-shaped groove 4 are inclined to both sides; this inclined groove is convenient for installation.

[0050] The fixing kit 2 includes a main board 5, the upper surface of the main board 5 is provided with a ring-shaped tenon 6, and the ring-shaped

[0051] The side surface of the tenon 6 is inclined to both sides, and the ring-shaped tenon 6 matches the size of the ring-shaped groove 4, so that the ring-shaped tenon 6 can be embedded in the ring-shaped groove 4; The lower surface of the main board 5 is provided with a fixed sleeve 7, the upper surfa...

Embodiment 2

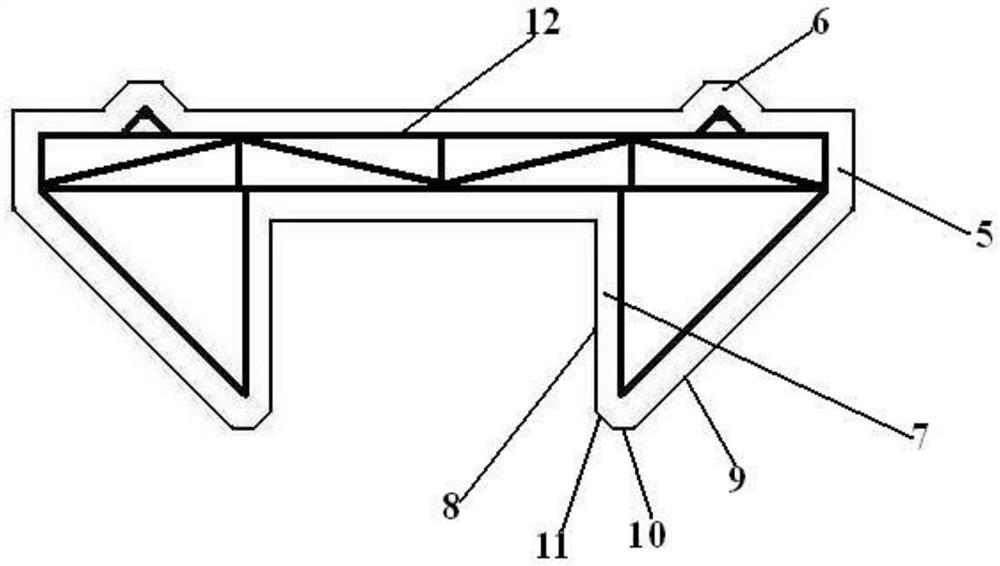

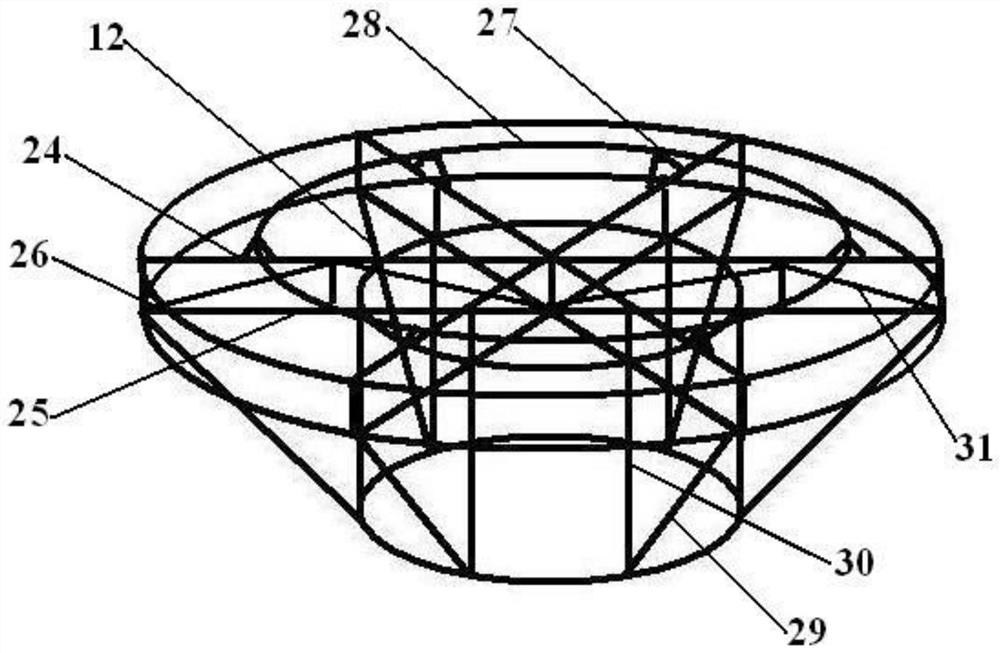

[0054] like figure 2 , 3 , 4, the stable support structure of the pile cap mainly comes from the reinforced keel 12 in the fixing kit 2. The fixing kit 2 is a reinforced keel concrete member, wherein the reinforced keel 12 includes tenon stirrups 13, tenon supports 14, upper main board stirrups 15, lower main board stirrups 16, upper main board straight bars 17, and lower main board straight bars. Ribs 18 , main plate column ribs 19 , upper sleeve stirrups 20 , lower sleeve stirrups 21 , sleeve column ribs 22 and sleeve diagonal ribs 23 .

[0055] The upper main plate stirrup 15 and the lower main plate stirrup 16 are circular stirrups of the same size, and the ends of several upper main plate straight bars 17 are welded to the upper main plate stirrup 15 through the center of the upper main plate stirrup to form the upper main plate steel mesh 24, the two ends of several lower main plate straight bars 18 are welded on the lower main plate stirrups 16 by the center of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com