Shale physical model and preparation method and device of saturated oil shale core sample

A technology of a physical model and a preparation device is applied in the preparation of oil-saturated shale core samples and the field of shale physical models, which can solve the problems of difficult oil-saturated cores and difficult acquisition of core samples, and achieves good results. , the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

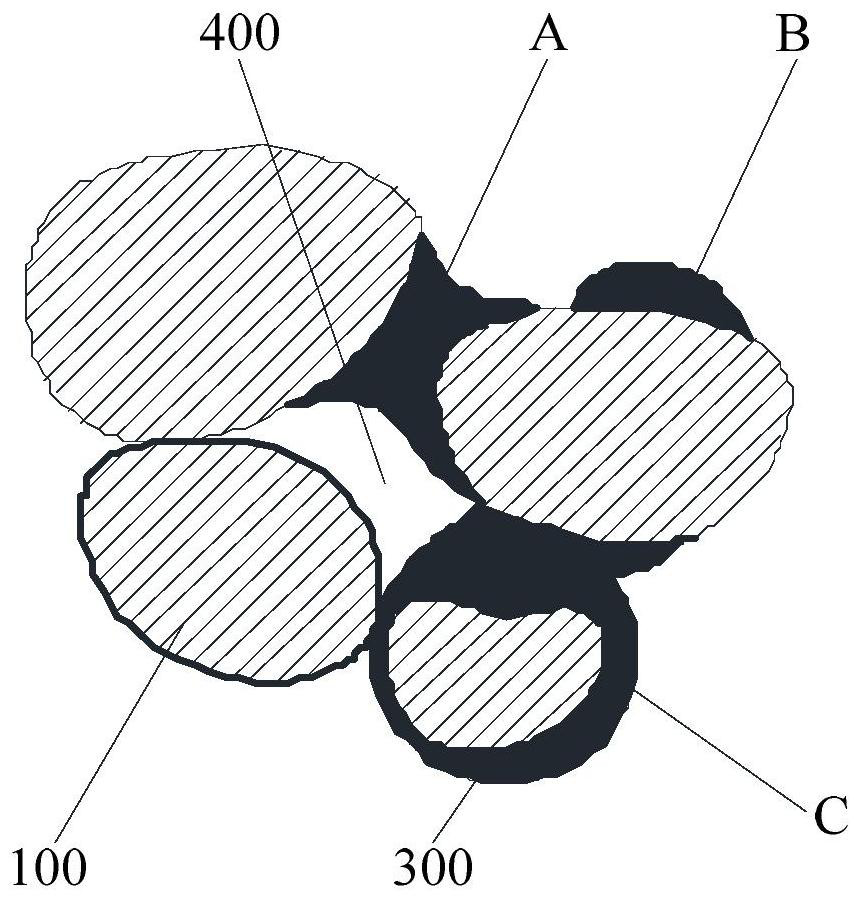

[0056] The method for preparing the physical model of shale in the prior art is to spray the cementing agent 300 directly on the surface of the sand grains 100. The existing problems are: such as figure 1 As shown, even if the droplets are small, they are distributed on the surface of the sand grains 100 in the form of local adsorption. During the pressing process, the cementation between the sand grains 100 is not uniform; the cementing agent 300 is too concentrated between the pores (such as figure 1 Middle position A), occupying a lot of pore space; the cement 300 is partially adsorbed (such as figure 1 In the middle position B), it does not have a cementing effect; the surface of the small particles is easily completely wrapped by the cementing agent 300 (such as figure 1 In the middle position C), the rock surface properties are lost.

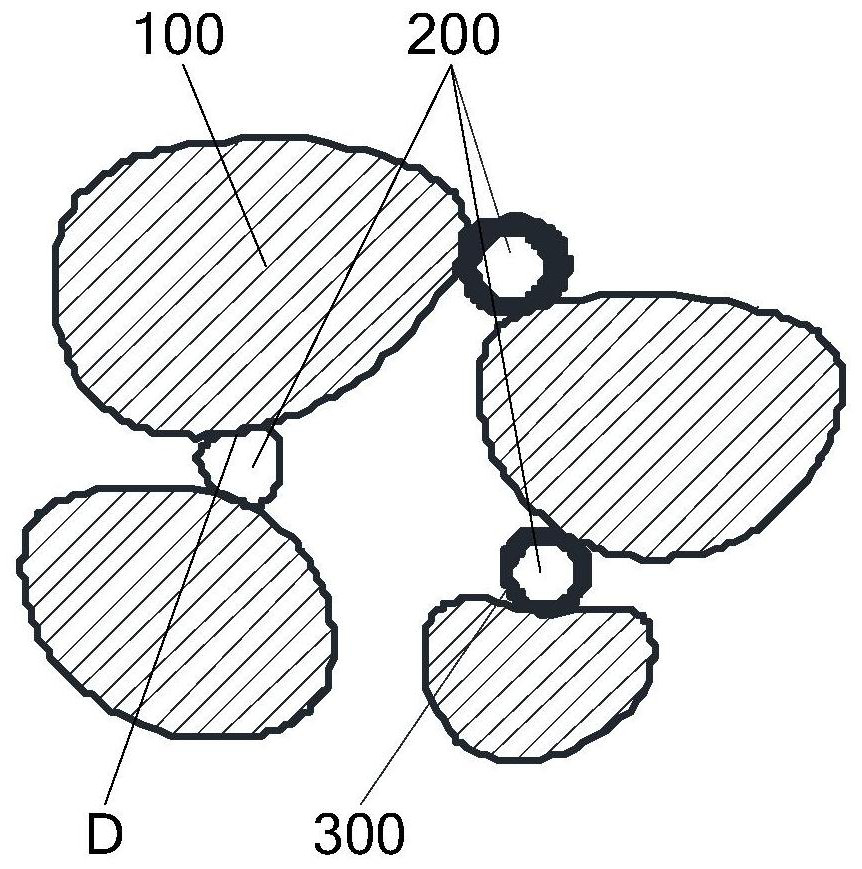

[0057] like figure 2 As shown, the present invention provides a physical model of shale, the components of which include sand particle...

Embodiment approach 2

[0066] See figure 2 , the present invention also provides a method for preparing a saturated oil shale core sample, the preparation method comprising:

[0067] Mixing the sand grains 100 and the water-absorbing solid-phase binder 200 uniformly to obtain a solid-phase raw material, wherein the particle size of the solid-phase binder 200 is smaller than that of the sand particles 100;

[0068] Dilute the binder 300 with water to obtain a binder solution;

[0069] The solid phase raw material is sprayed with the binder solution and mixed evenly to obtain the raw material to be pressed, for example, the spraying method is ultrasonic spraying;

[0070] The raw material to be pressed is immersed in oil for pressing to obtain a saturated oil shale core sample.

[0071] It is known from the existing research results that the genesis of shale oil is the direct transformation of organic matter in the rock pores, which is significantly different from the accumulation process of first ...

Embodiment approach 3

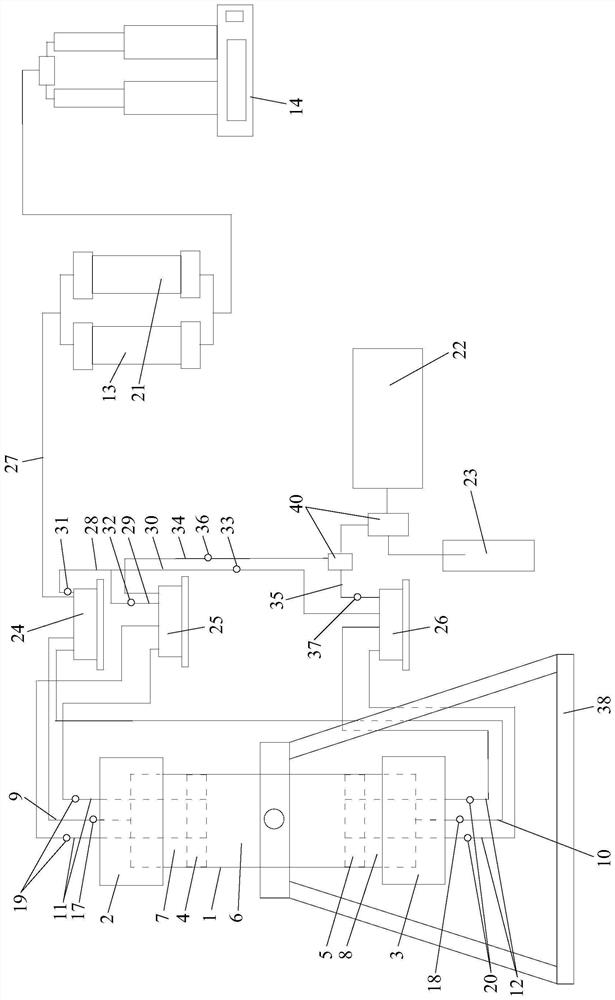

[0077] like image 3 As shown, the present invention also provides a preparation device for saturated oil shale core samples, which is used for the preparation method of saturated oil shale core samples in Embodiment 2, for preparing saturated oil shale core samples, the preparation device includes: A pressing cylinder, an upper pressurizing pipe 9 , a lower pressurizing pipe 10 , an upper communicating pipe 11 , a lower communicating pipe 12 , a pressurizing container 13 for accommodating pressurized liquid, and a pressurizing pump 14 .

[0078] Wherein, the pressing cylinder comprises a cylinder body 1, an upper end cover 2 and a lower end cover 3 respectively arranged at the upper and lower ends of the cylinder body 1, and an upper piston 4 and a lower piston 5 arranged in the cylinder body 1. The upper end cover 2 and the cylinder body 1. Removably sealed connection, the lower end cover 3 and the cylinder body 1 are detachably sealed connection, the upper piston 4 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com