A filling material for filling mining

A filling material and filling paste technology, applied in cement production and other directions, can solve the problems of slow paste solidification reaction, reduced filling efficiency, low paste curing temperature, etc., to prevent segregation and subsidence, improve filling efficiency, and workability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

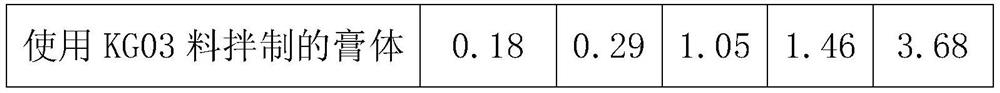

Embodiment 1

[0022] The filling material is made of the following raw materials in parts by weight: 52 parts of 325 cement; 34 parts of slag fine powder; 7 parts of calcium sulfoaluminate; 4 parts of calcium aluminate; 2 parts of calcium oxide; 1 part of sodium carbonate. After the filling material is processed by drying, grinding and other processes, a high-fineness and high-activity powder is obtained. The content of particles smaller than 0.045mm in the powder is not less than 67.03%. The particle size of the powder meets the requirement of stirring with water to form a viscous paste slurry, which can well wrap the sticky gangue particles and prevent the gangue particles from segregating and sinking. The bulk density of filling material powder is 0.81KG / L, which belongs to medium density powder. The filling material itself has a certain cementing effect, and it can also be used alone in projects that do not require high compression resistance. The compressive strength is not less than ...

Embodiment 2

[0024] There are active components in the filling material, and the interaction with fly ash and gangue powder is obvious under the action of aqueous solution. The active substances of each other excite each other, a chemical reaction occurs, and anions and cations adsorb and precipitate each other to form a dense solid.

[0025] 2R - +Ca 2+ =CaR 2

[0026] al 3+ +3OH - =Al(OH) 3

[0027] 2H 2 O+SO 4 2- +Ca 2+ =CaSO 4 .2H 2 o

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com