High-voltage switch aluminum magnesium alloy supporting cylinder sand core mold and assembling method thereof

An aluminum-magnesium alloy and high-voltage switch technology, applied in the field of casting molds, can solve problems such as shrinkage porosity and shrinkage cavities, unusable castings, and affecting the casting effect of the support cylinder, so as to reduce the defective rate, ensure the casting effect, and avoid shrinkage cavities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

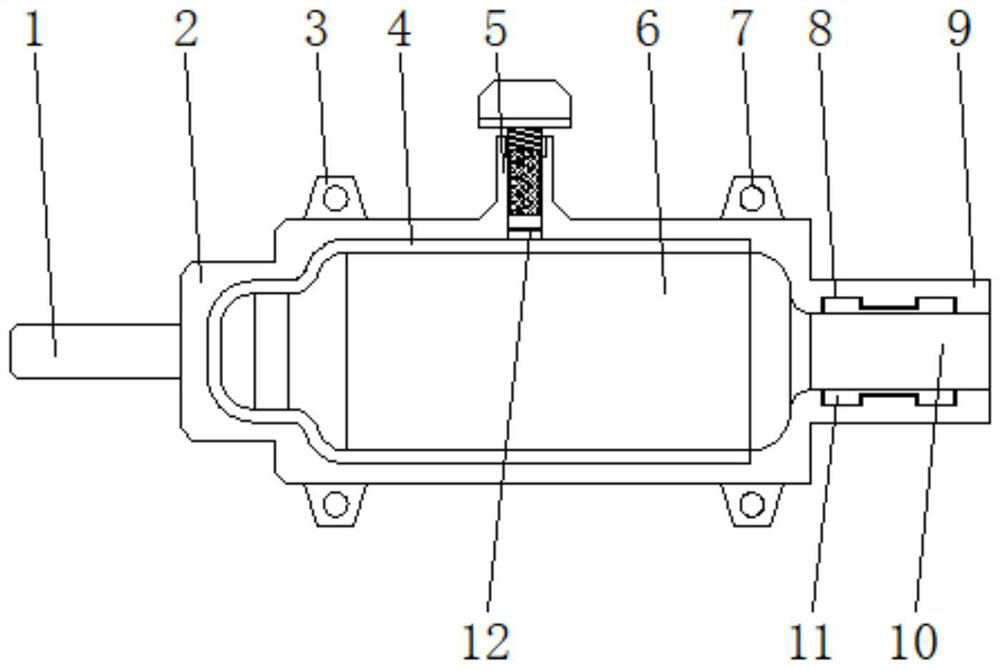

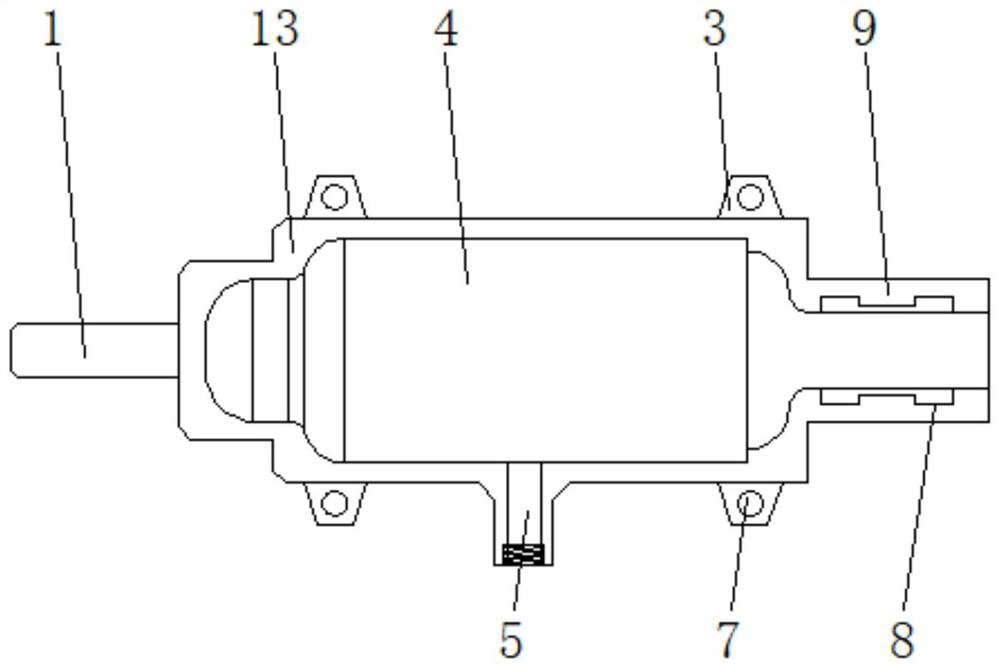

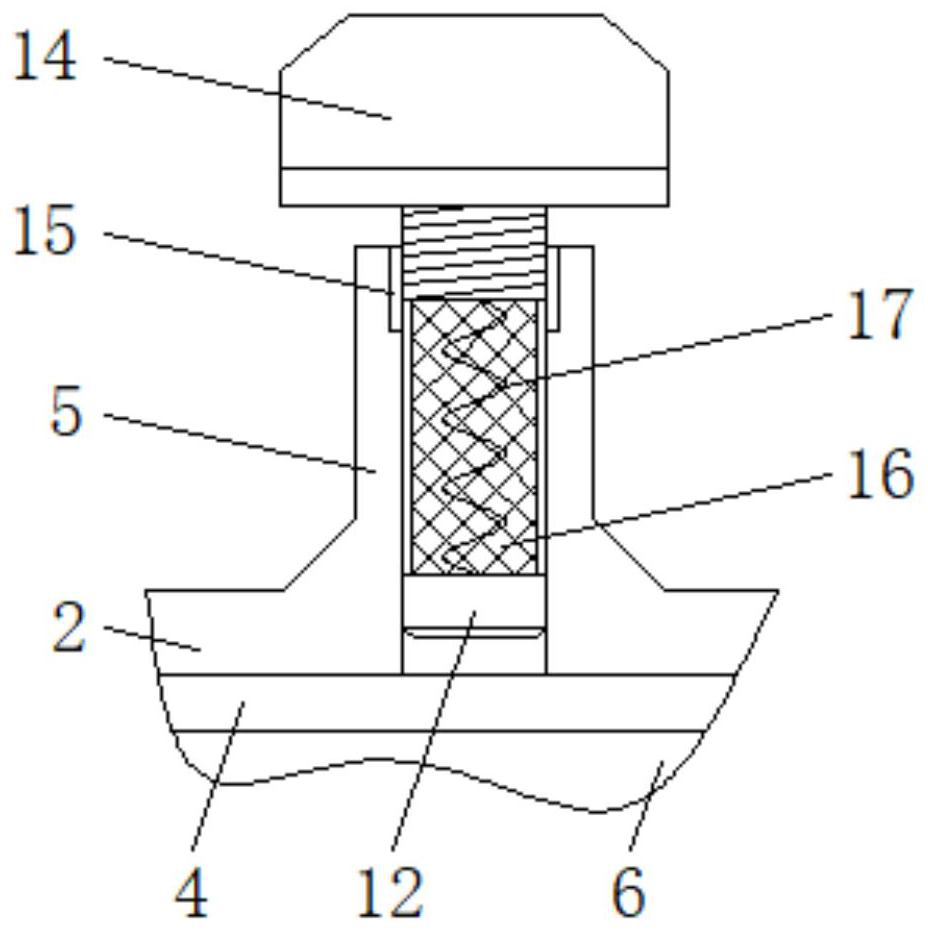

[0026] A high-voltage switch aluminum-magnesium alloy support cylinder sand core mold, including a mold body, a first mold 2, a material injection port 5, a sand core 6, a limit groove 8, a second shaft 9, a second mold 13 and a knob 14, the mold The body is composed of a first mold 2 and a second mold 13. The mold body is provided with a sand core 6. The first mold 2 and the second mold 13 are both provided with a casting groove 4. The first mold 2 and the second mold 13 have both ends. A first rotating shaft 1 and a second rotating shaft 9 are respectively provided, a limiting groove 8 is provided inside the second rotating shaft 9, an exhaust port 10 is provided at one end of the sand core 6, the inner wall diameter of the casting groove 4 is larger than the outer wall diameter of the sand core 6, and the exhaust port 10 penetrates through the inside of the second rotating shaft 9, and the outer wall of the exhaust port 10 is provided with a limit ring 11 which is fitted wit...

Embodiment 2

[0030] The assembly process of the mold body is as follows:

[0031] S1: Separate the first mold 2 from the second mold 13, place the sand core 6 inside the casting groove 4, and fit the limit ring 11 on the surface of the exhaust port 10 with the limit groove 8 inside the second shaft 9 combine;

[0032] S2: The staff matches the first mold 2 and the second mold 13 with each other, connects the connecting blocks 3 through the bolt through the screw hole 7, and stably combines the first mold 2 and the second mold 13 to form a mold body;

[0033] S3: The molten aluminum-magnesium alloy is injected into the mold body through the injection port 5, the sealing block 12 is inserted into the injection port 5, and the knob 14 is stably connected to the screw port 15 to seal and keep the injection port 5.

[0034] Working principle: The sand core 6 is placed inside the mold body. The sand core 6 is designed in a hollow form, and an exhaust port 10 is provided at one end of the sand c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com