Dust removal structure for mechanical finish machining grinding device and using method of dust removal structure

A technology of machinery and dust intake, applied in the field of mechanical finishing, can solve the problems of unfavorable flying dust collection, easy to cause dust, blockage at the inlet, etc., and achieve the effect of expanding the scope of dust collection and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0056] In order to further explain the above embodiments better, the present invention also provides an embodiment, a method for using a dust removal structure for a mechanical finishing grinding device, comprising the following steps:

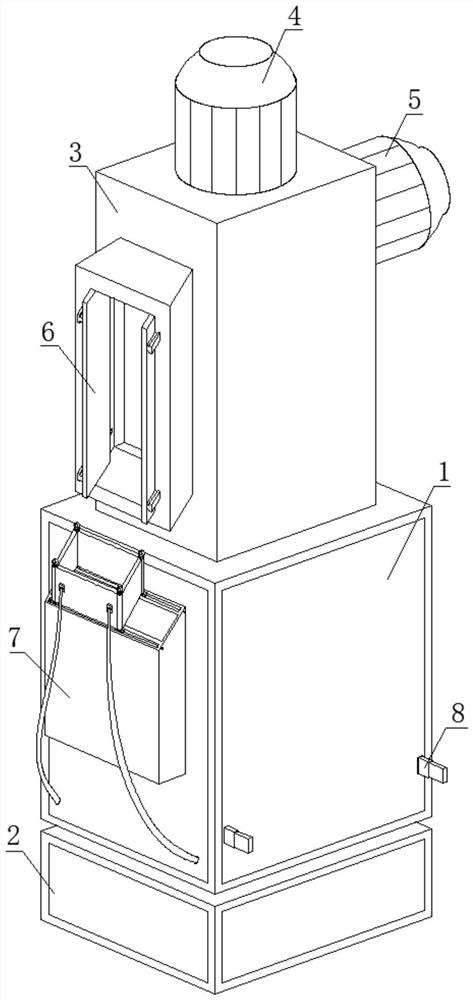

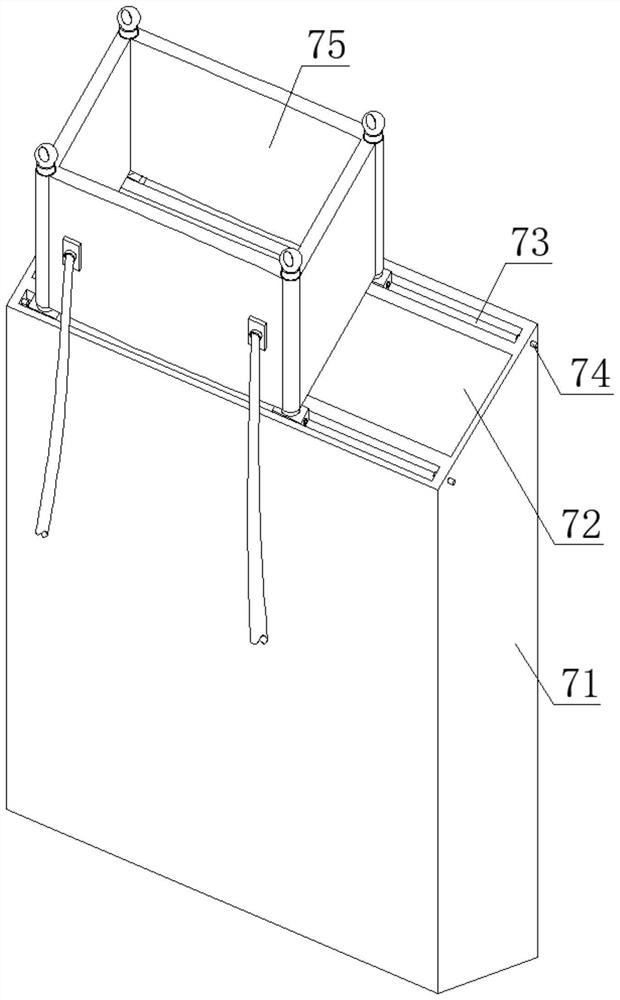

[0057] S1: During the grinding process, place the whole at the grinding device, align the dust intake mechanism 6 with the grinding part of the parts, start the main air pump B5 at the same time, and pull out the display plate 62 from the feeding box 61 to expand the dust suction range;

[0058] S2: The inhaled flying dust will gradually accumulate on the placement plate 91. With the continuous accumulation of the flying dust, the overall weight of the placement plate 91 will increase, the placement plate 91 will move down along the wall groove 33, and the ejector rod 343 will push up The center block 95 is opened, and the lower bottom surface of the placement plate 91 will touch the control switch 341, so that the main air pump A4 is turned on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com