Paperboard barrel edge pressing module for paperboard barrel production line

A production line and cardboard technology, applied in paper/cardboard containers, papermaking, packaging, etc., can solve problems such as low degree of automation, too many parts, difficult maintenance, etc., to facilitate data collection, improve production efficiency, and reduce replacement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below.

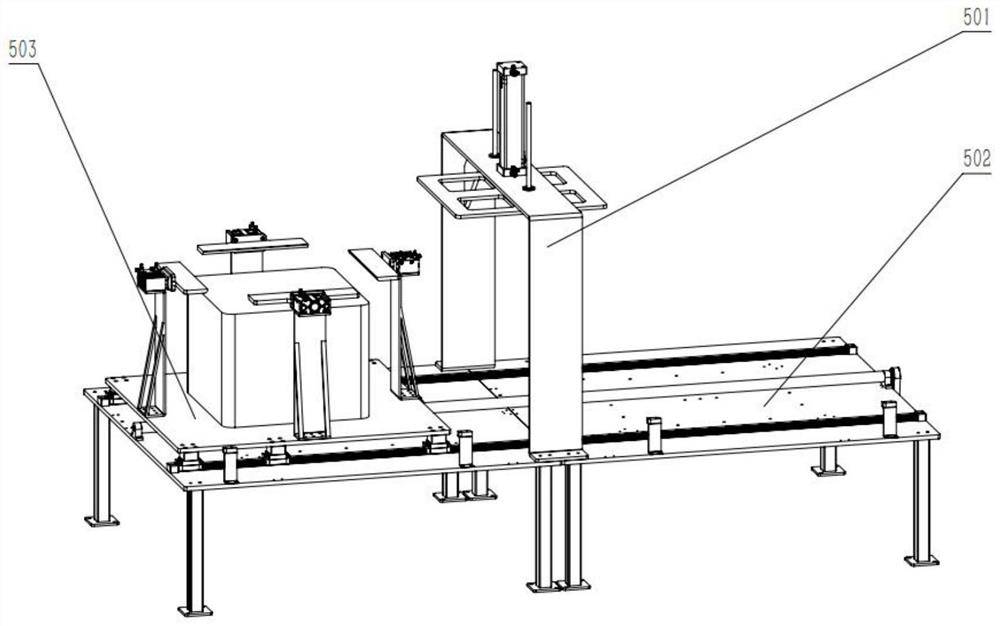

[0028] like Figure 1 to Figure 7 As shown, a cardboard barrel pressing module of a cardboard barrel production line includes:

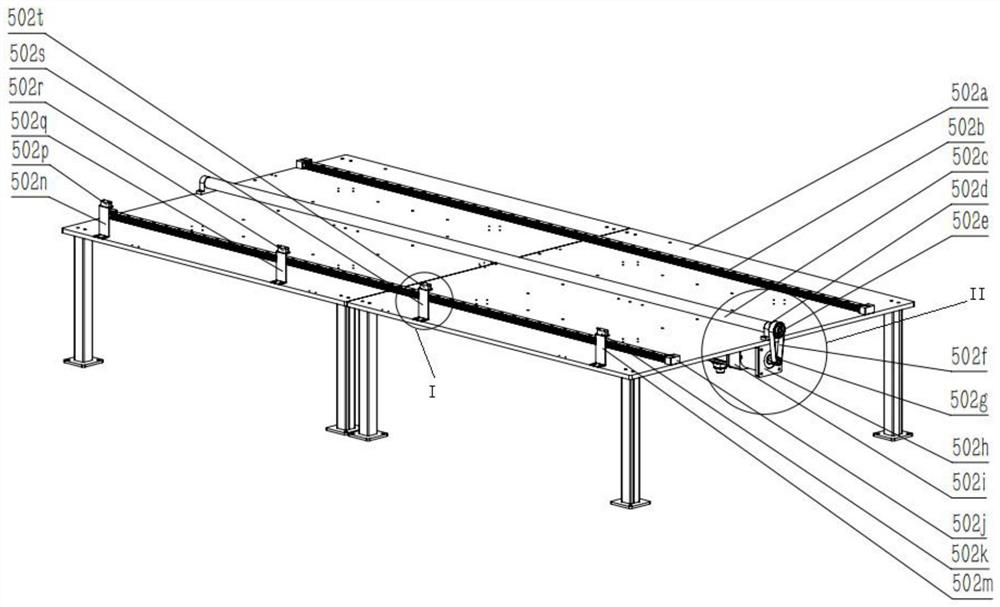

[0029] The cardboard barrel crimping module base 502 is used to play the role of a bearing component;

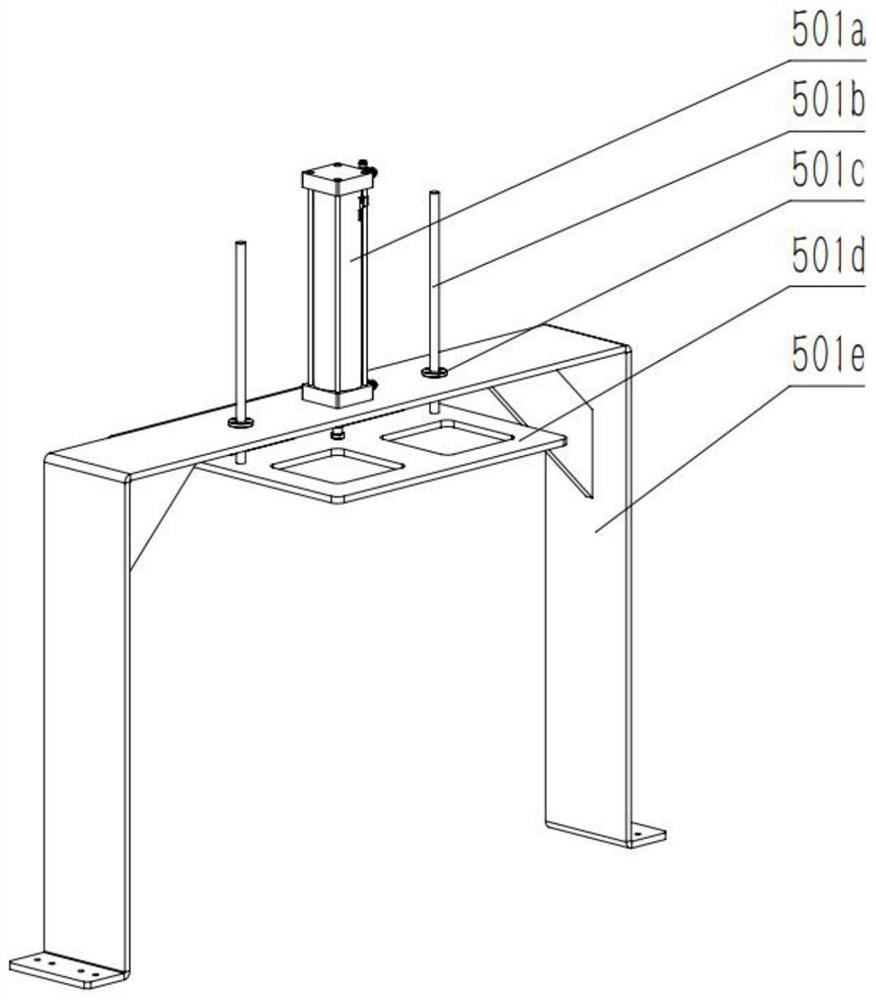

[0030] The cardboard barrel crimping holding module 501 is arranged on the cardboard barrel crimping module base 502, and is used for pressing the four sides of the cardboard barrel at the crimping station;

[0031] The cardboard barrel crimping positioning and transporting module 503 is arranged on the cardboard barrel crimping module base 502 and is used for changing the position of the cardboard barrel crimping holding module 501 .

[0032] The cardboard barrel hemming module base 502 includes a cardboard barrel hemming module stand 502a fixed at a proper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com