Strong-sunscreen umbrella fabric and preparation method thereof

A technology for fabrics and umbrellas, applied in the field of strong sunscreen umbrella fabrics and its preparation, can solve problems such as adverse effects of consumer experience, reduction of sunscreen function, coating wear, etc., achieve high marketing value, prevent harm to the human body, Produce convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

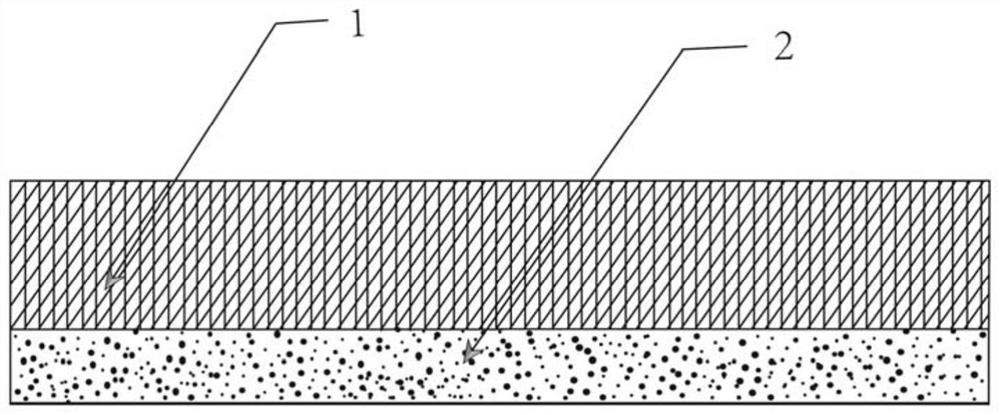

[0030] like figure 1 As shown, a strong sunscreen umbrella fabric, the umbrella fabric is a two-layer composite structure, including a waterproof fabric layer 1 and an anti-ultraviolet composite film layer from the outside to the inside, and the anti-ultraviolet composite film layer is a black and white composite film layer 2 .

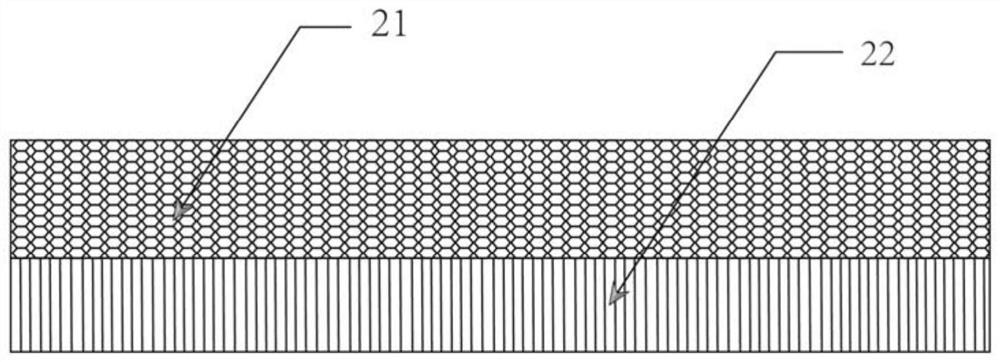

[0031] like figure 2 As shown, one side of the black and white composite film layer 2 is a white reflective layer 21 , and the other side is a black layer 22 , and the white reflective layer 21 is attached to the waterproof fabric layer 1 . The white reflective layer 21 contains 15% by mass of reflective particles SiO 2 , the black layer 22 contains 20% by mass of light-absorbing particle carbon black.

[0032] The waterproof fabric layer 1 is made of polyester woven high-density grey fabric through waterproof finishing. The linear density of the yarns in the polyester woven high-density fabric is 30D, and the sum of the warp and weft densities is...

Embodiment 2

[0044] like figure 1 As shown, a strong sunscreen umbrella fabric, the umbrella fabric is a two-layer composite structure, including a waterproof fabric layer 1 and an anti-ultraviolet composite film layer from the outside to the inside, and the anti-ultraviolet composite film layer is a black and white composite film layer 2 .

[0045] like figure 1 As shown, one side of the black and white composite film layer 2 is a white reflective layer, the other side is a black layer 22 , and the white reflective layer 21 is attached to the waterproof fabric layer 1 . The white reflective layer 21 contains 5% by mass of reflective particles SiO 2 , the black layer 22 contains 10% by mass of light-absorbing particle carbon black.

[0046] The waterproof fabric layer 1 is made of polyester woven high-density grey fabric through waterproof finishing. The linear density of the yarn in the polyester woven high-density fabric is 20D, and the sum of the warp and weft densities is 400 thread...

Embodiment 3

[0058] like figure 1 As shown, a strong sunscreen umbrella fabric, the umbrella fabric is a two-layer composite structure, including a waterproof fabric layer 1 and an anti-ultraviolet composite film layer in turn from the outside to the inside, and the anti-ultraviolet composite film layer is a black and white composite film layer 2 .

[0059] like figure 2 As shown, one side of the black and white composite film layer 2 is a white reflective layer 21, and the other side is a black layer 22. The white reflective layer 21 and the waterproof fabric layer 1 are attached together. The white reflective layer 21 contains 15% by mass of reflective particles SiO 2 , the black layer 22 contains 15% by mass of light-absorbing particle carbon black.

[0060] The waterproof fabric layer 1 is made of polyester woven high-density grey fabric through waterproof finishing. The linear density of the yarns in the polyester woven high-density fabric is 10D, and the sum of the warp and weft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com