Pneumatic sand adding system and method for electric furnace

An electric furnace and pneumatic technology, which is applied in the field of electric furnace pneumatic sanding system, can solve the problems of low operating efficiency, high labor intensity, and low safety, and achieve the effects of simple structure, reduced working intensity, and improved sanding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

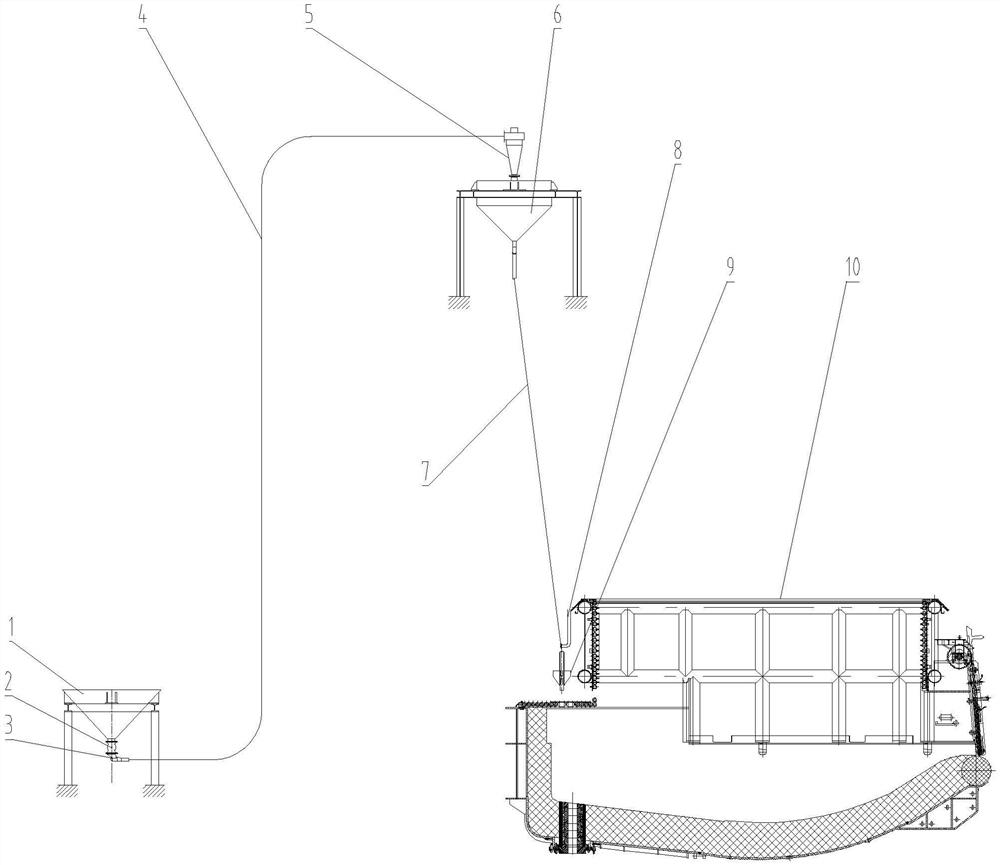

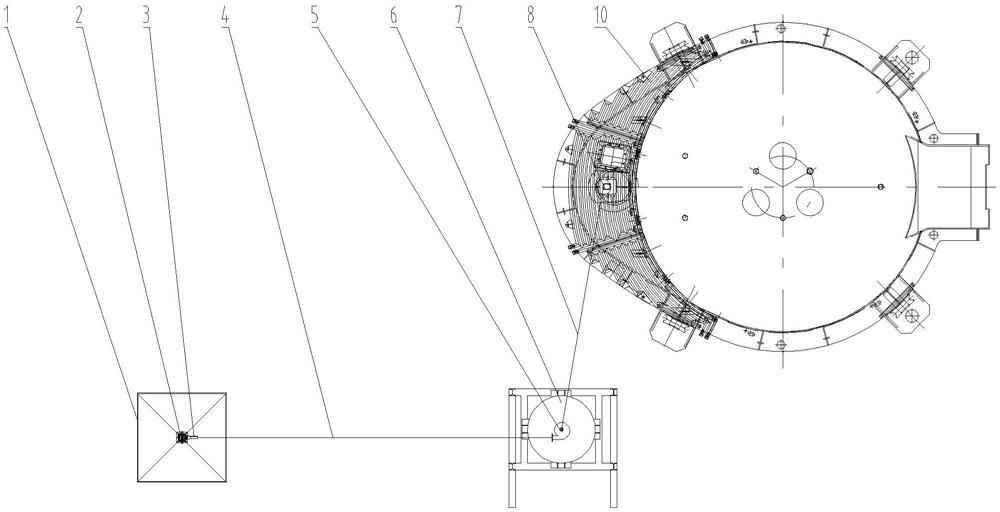

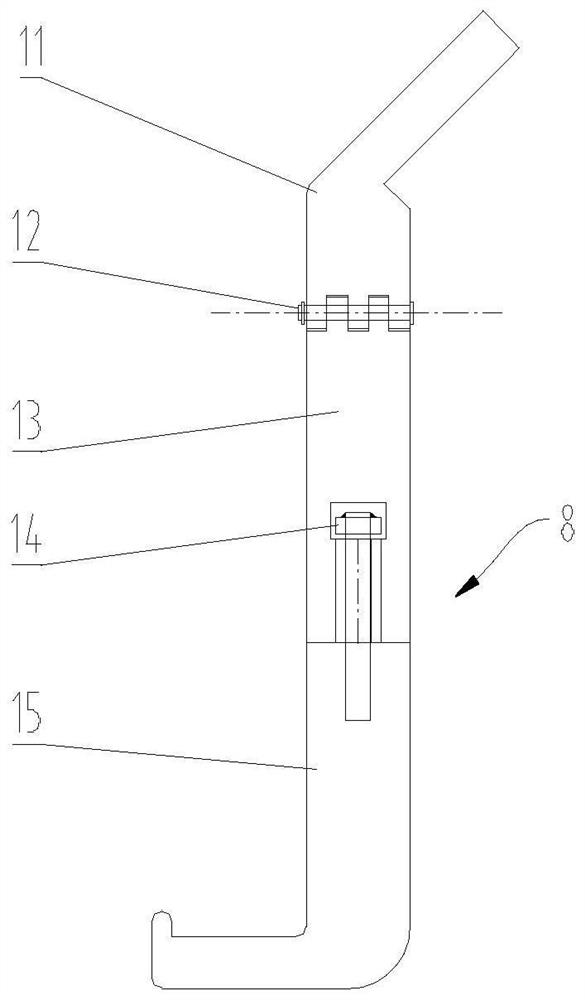

[0033] like Figure 1 to Figure 6 As shown, an electric furnace pneumatic sanding system of the present invention includes a raw material bin 1, an electric furnace 10, a receiving bin 6 located higher than the electric furnace 10, and a furnace shell sanding port (that is, a tapping port) installed on the electric furnace 10. The multi-degree-of-freedom hook device 8 above, the multi-degree-of-freedom hook device 8 is hung with a self-locking sand feeding bucket 9, and the multi-degree-of-freedom hook device 8 can adjust the position with multiple degrees of freedom, thereby driving the self-locking sand feeding bucket 9 hung on it. The position of the sand bucket 9 is adjusted, so that the drainage sand drop point of the self-locking sand filling bucket 9 is aligned with the position of the tapping hole of the electric furnace; the outlet of the raw material bin 1 is connected with a pneumatic conveying mechanism for conveying drainage sand materials, and a pneumatic conveyin...

Embodiment 2

[0039] On the basis of Example 1, as Figure 1-Figure 7 As shown, the electric furnace pneumatic sanding system also includes a controller 28, the tail end of the injector 3 is connected to the compressed air source through a solenoid valve 31, a material level switch 61 is provided on the top of the receiving bin 6, and the lock The gas device 2 , the solenoid valve 31 and the material level switch 61 are respectively connected to the controller 28 through lines. When feeding, when the full signal of the material level switch 61 is transmitted to the controller 28, the controller 28 controls the air lock 2 and the solenoid valve 31 to stop feeding; The motor of the air lock 2 is interlocked to ensure that the material is ventilated and then fed at the beginning of the feeding, and that the material is stopped first and then the gas is stopped after the feeding is completed.

Embodiment 3

[0041] The sanding method of the electric furnace pneumatic sanding system described in embodiment 1 or 2, the steps are as follows:

[0042] S1, feeding: the drainage sand in the raw material warehouse 1 is mixed with the compressed air in the ejector 3 through the air lock 2 to form a gas-solid two-phase fluid, and then the gas-solid two-phase fluid is passed through the feeding pipe 4 is sent to the unloader 5, and the unloader 5 settles the drainage sand in the gas-solid two-phase fluid into the receiving bin 6, and the gas is sucked away by the dust suppression system of the electric furnace itself;

[0043] S2. Sand adding: hang the self-locking sand adding bucket 9 on the multi-degree-of-freedom hook device 8, and then send the drainage sand in the receiving bin 6 to the self-locking sand adding bucket 9 through the hose 7 by its own weight. Through the multi-degree-of-freedom hook device 8, the landing point of the drainage sand is aligned with the position of the tapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com