Coated fireproof glass with sunlight control and low-radiation functions and preparation method thereof

A solar control and fireproof glass technology, applied in the field of glass manufacturing, can solve the problems of solar control, low radiation, general fire resistance, erosion, and coated glass cannot be used in a single layer, and achieve excellent chemical stability and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

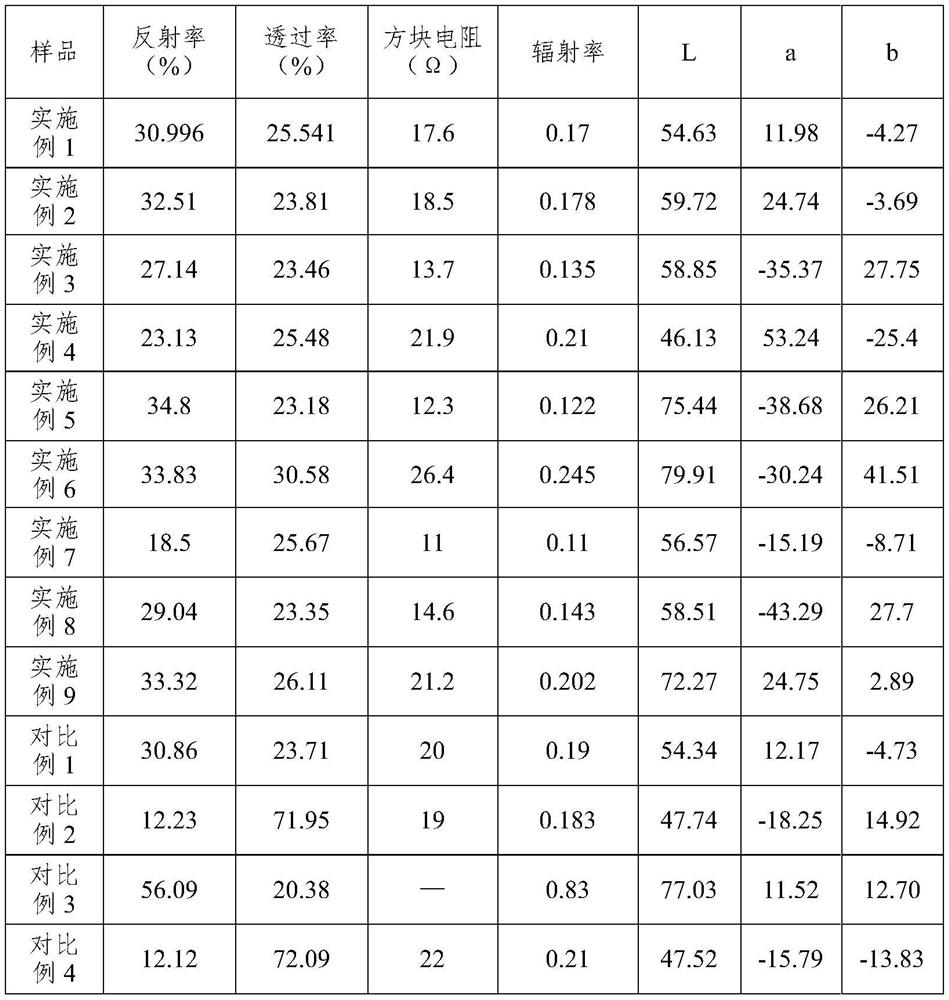

Examples

Embodiment 1

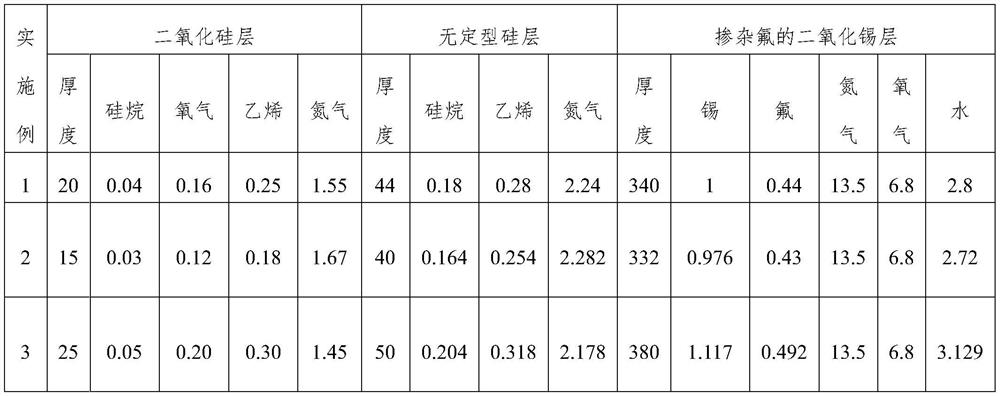

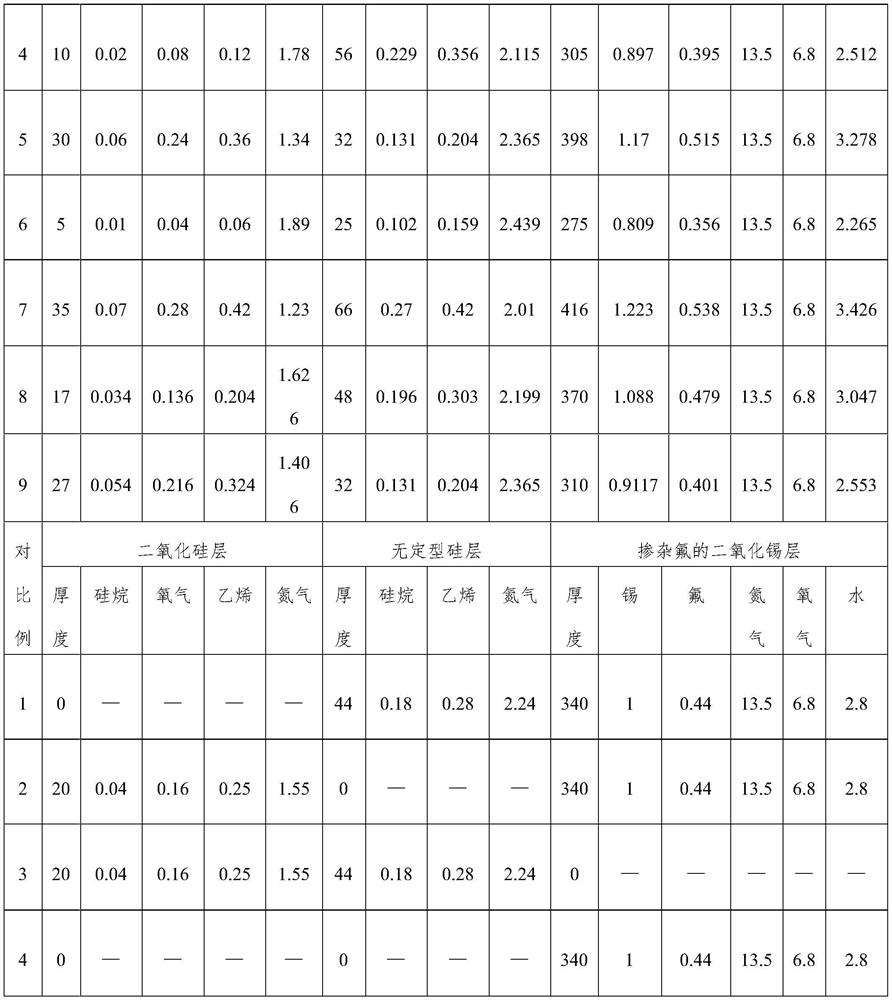

[0063] In this embodiment, a coated fireproof glass is prepared through the following steps

[0064] (1) will be 0.04L / m 2 Silane, 0.16L / m 2 of oxygen, 0.25L / m 2 of ethylene, 1.55L / m 2 The first mixed gas composed of nitrogen gas is introduced into the reactor to react on the surface of the borosilicate glass substrate to prepare a silicon dioxide layer.

[0065] (2) will be 0.18L / m 2 Silane, 0.28L / m 2 of ethylene, 2.24L / m 2 The second mixed gas composed of nitrogen gas is introduced into the reactor, and reacts on the surface of the silicon dioxide layer obtained in step (1) to prepare an amorphous silicon layer;

[0066] (3) will be made by 1L / m 2 Trichloromonobutyltin steam, 0.44L / m 2 of trifluoroacetic acid vapor, 13.5L / m 2 of nitrogen, 6.8L / m 2 of oxygen, 2.8L / m 2 The third mixed gas composed of water vapor is introduced into the reactor to react on the surface of the amorphous silicon layer obtained in step (2) to obtain coated fireproof glass.

[0067] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com