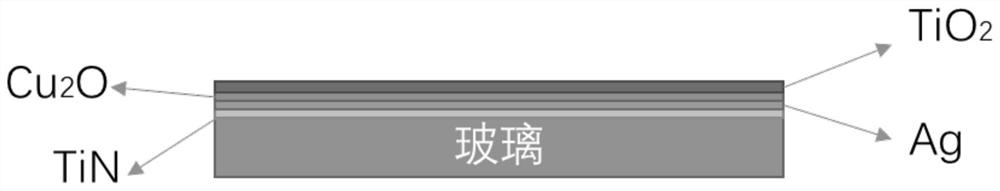

A kind of multi-layer composite film door and window glass with double function and preparation method thereof

A multi-layer composite, door and window glass technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of many film layers, cumbersome preparation process, and few functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

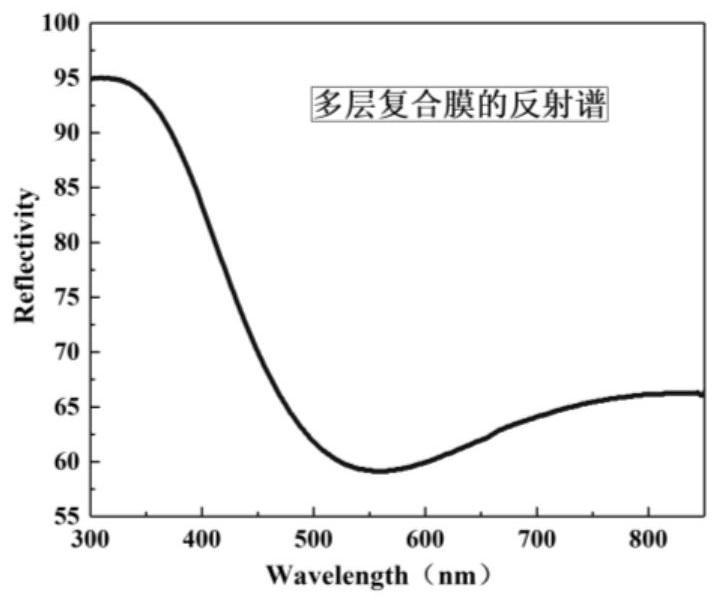

[0024] A multi-layer composite film for door and window glass with dual functions of low radiation and self-cleaning and a preparation method thereof, the specific steps of the preparation method are as follows:

[0025] 1) Substrate glass pretreatment

[0026] ①Put the substrate glass into deionized water with detergent, and ultrasonically clean it for 10 minutes to remove surface dust and oil;

[0027] ② Take out the substrate glass, rinse off the detergent on the surface with deionized water, and then put it into deionized water for ultrasonic cleaning for 20 minutes;

[0028] ③Take out the substrate glass, put it in absolute ethanol (99.99% pure), and clean it ultrasonically for 10 min;

[0029] ④ Take out the substrate glass, put it into deionized water again, and clean it ultrasonically for 10 minutes;

[0030] ⑤Take out the substrate glass, put it in acetone (99.99% purity), and clean it ultrasonically for 10 min;

[0031] ⑥ Take out the substrate glass, put it in ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com