A kind of manufacturing method of zone-removing film can be baked and bendable low-emissivity coated laminated glass

A low-e coating and laminated glass technology, which is applied in the manufacture of bakeable low-e coating laminated glass, can solve the problems of no low-e coating laminated glass removal technology, irregular graphics, glass scratches, etc., to avoid Film layer corrosion, short drying time, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

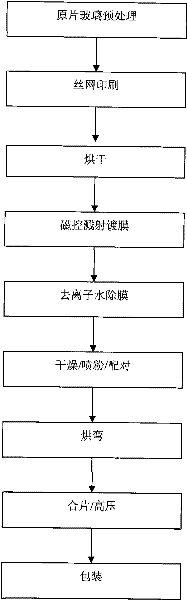

[0043] A kind of manufacturing method of the bakeable bendable low-emissivity coated laminated glass of region removing film, such as figure 2 Shown, the technological process of this method comprises the following steps:

[0044] (1) Pre-treatment of original glass: The original green float glass with a thickness of 1.8mm is sliced, loaded, cut, edged, washed and dried to obtain automotive-grade original glass, which is called "large piece" glass ;

[0045] (2) Screen printing: use water-soluble paint as a film-removing medium, and apply it on the area around the surface of the original automotive-grade glass that does not need to be coated by screen printing. The thickness of the film is 40 μm. The water-soluble paint is formed by film Composition of substance, auxiliary agent and organic solvent, wherein the content of acrylic resin is 40% (wt%), the auxiliary agent is photoinitiator, the content is 2% (wt%), and the balance is organic solvent ethanol, film-forming substa...

Embodiment 2

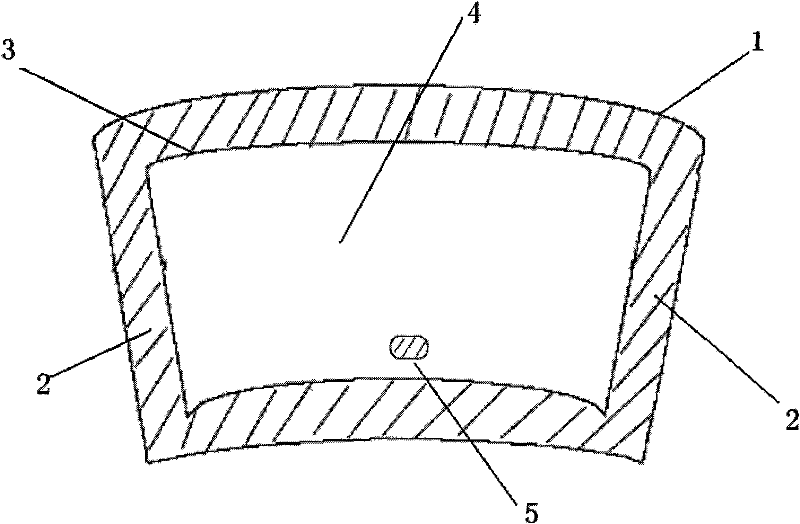

[0051] A method for manufacturing a bakeable and bendable low-emissivity coated laminated glass with regional film removal, finally obtaining products such as figure 1 As shown, the method includes the following steps:

[0052] (1) Pre-treatment of original glass: The original green float glass with a thickness of 1.8mm is sliced, loaded, cut, edged, washed and dried to obtain automotive-grade original glass, which is called "large piece" glass ;

[0053] (2) Screen printing: use water-soluble paint as a film removal medium, and apply the water-soluble paint along the outer edge 1 of the original automotive-grade glass to the area 2 around the glass surface that does not need to be coated and the base area 5 of the glass surface through the screen printing process. The thickness of coating film is 80 μ m, and this water-soluble coating is made up of film-forming substance, auxiliary agent and organic solvent, and wherein polyethylene resin content is 65% (wt%), and auxiliary ...

Embodiment 3

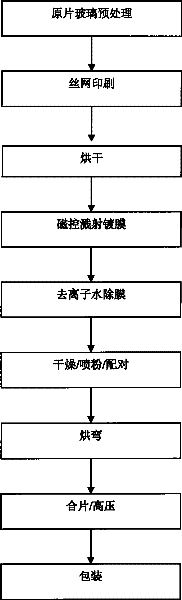

[0059] A method for manufacturing a bakeable and bendable low-emissivity coated laminated glass with regional film removal, the method comprises the following steps:

[0060] (1) Original glass pretreatment: the original transparent float glass sheet with a thickness of 2.1mm is sliced, loaded, cut, edged, washed and dried to obtain automotive-grade original glass, which is "large sheet" glass ;

[0061] (2) Screen printing: use water-soluble paint as a film-removing medium, and apply it on the area around the surface of the original automotive-grade glass that does not need to be coated by screen printing. The thickness of the film is 30 μm. The water-soluble paint is formed by film Composition of substance, auxiliary agent and organic solvent, wherein the content of acrylic resin is 35% (wt%), the auxiliary agent is photoinitiator, the content is 2% (wt%), and the balance is organic solvent acetone, film-forming substance and organic solvent are water soluble;

[0062] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com