Construction method for temporary jump drainage of bilge well

A construction method and technology of sewage wells, which are applied in sewage wells, waterway systems, water supply devices, etc., can solve the problems of unknown underground geology and long relocation cycle time, etc., to reduce impact, maintain safety, and improve connection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] like figure 1 As shown, a construction method for temporarily skipping a sewage well according to an embodiment of the present invention includes the following steps:

[0036] S1: First, the staff will investigate the flow direction of the sewage according to the current situation, and at the same time determine the plan and the distribution map of the underground pipeline to release the well position of the jump discharge well. When the inclination is not more than 1%, a steel casing is buried. The inner diameter of the casing is 20cm larger than the diameter of the pile. The top surface of the cylinder is 20-30cm higher than the construction ground;

[0037] S2: When a positive circulation drilling rig is used, the geological profile is drawn according to the geological and hydrological data provided by the construction design, and different drill bits, drilling pressure, drilling speed and appropriate mud proportion are selected for different geological layers. Dril...

Embodiment 2

[0048] like Figure 8 As shown in the comparison example 1, another embodiment of the present invention is: multiple groups of No. 1 magnets 9 are fixed inside the roller 31 ; Described No. 1 magnet 9 and No. 2 magnet 91 magnetic repulsion; During work, in the contact process of roller 31 and wave groove 3, the magnetic repulsion between No. 1 magnet 9 and No. 2 magnet 91 can assist roller 31 When moving, the magnetic force of No. 1 magnet 9 and No. 2 magnet 91 are used to repel each other, which can accelerate the disengagement speed of the roller 31 and the wave groove 3, and provide a smooth support for the outward disengagement of the pressing plate 23.

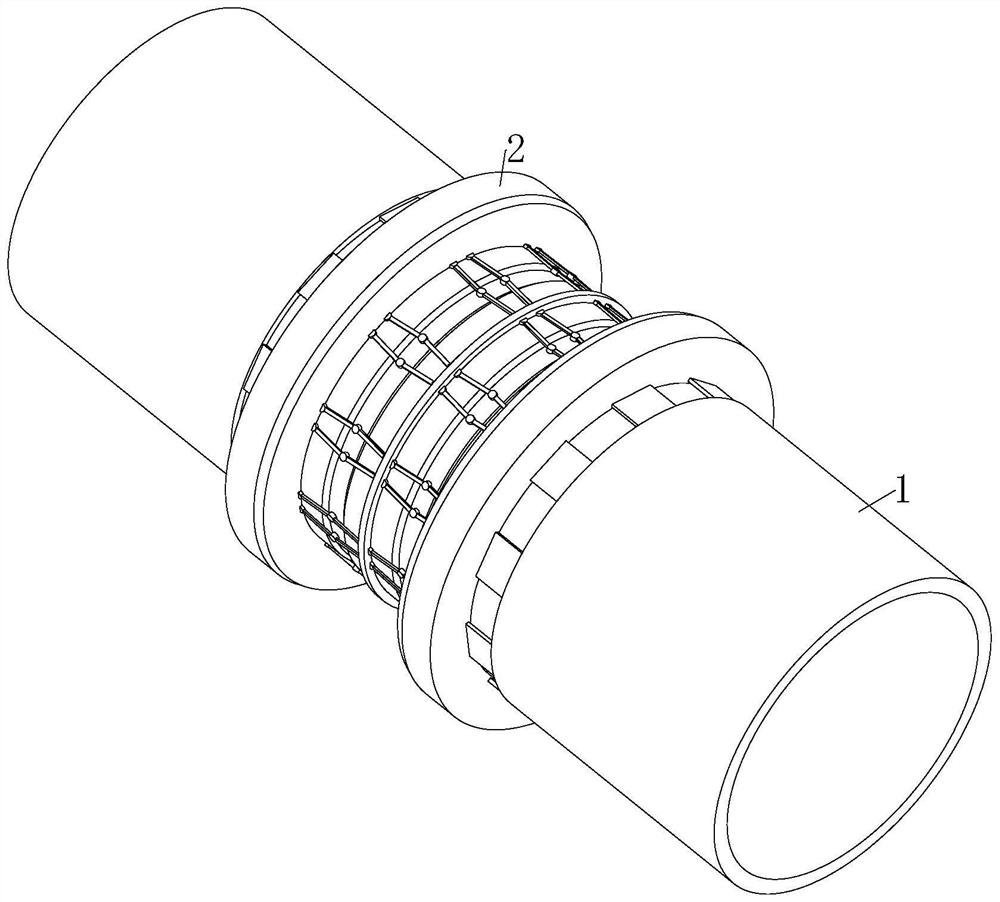

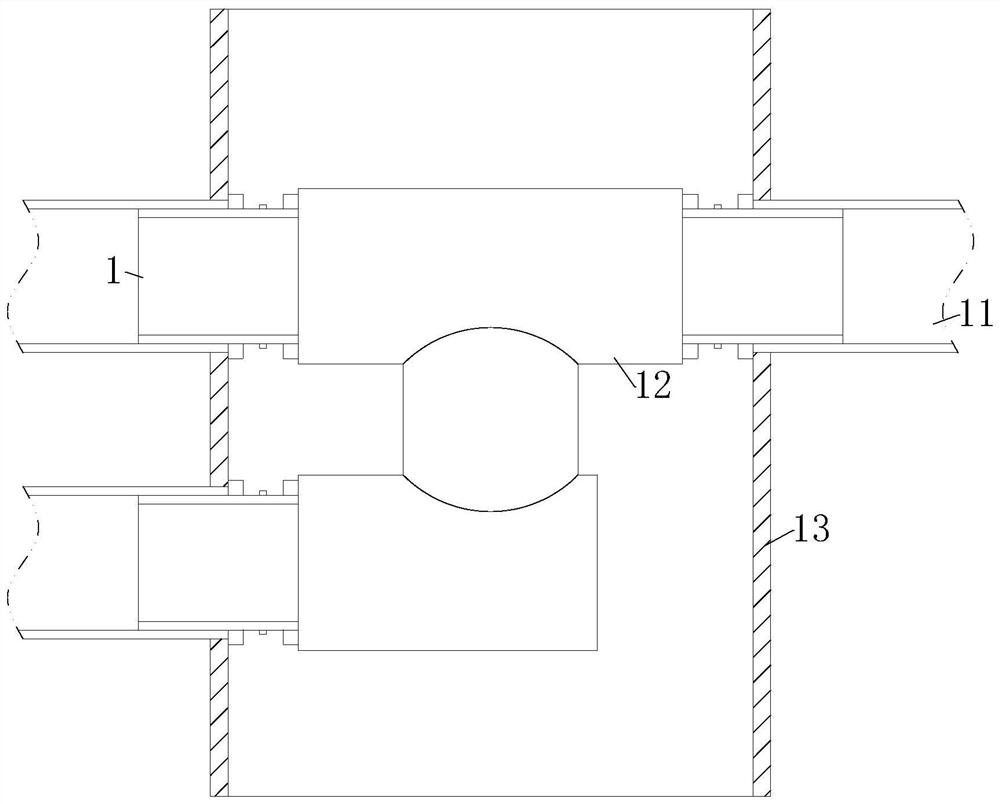

[0049] When working, the tee pipes 12 installed on the ends of the multiple sets of sewage pipes 11 and the tee pipes 12 can communicate with each other and drain the sewage, so as to keep the sewage well 13 in a dry environment. When the pipe 1 communicates with the sewage pipe 11 and the tee pipe 12, according to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com