Nondestructive mixed transportation device for krill

A krill and mixed transportation technology, applied in the field of marine fishery, can solve the problems affecting the integrity of krill, impact and collision of krill, etc., and achieve the effects of reducing extrusion damage, reducing impact force and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

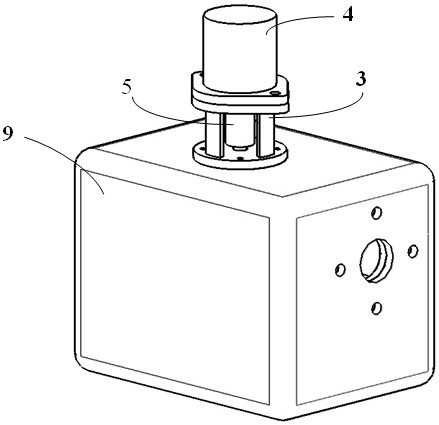

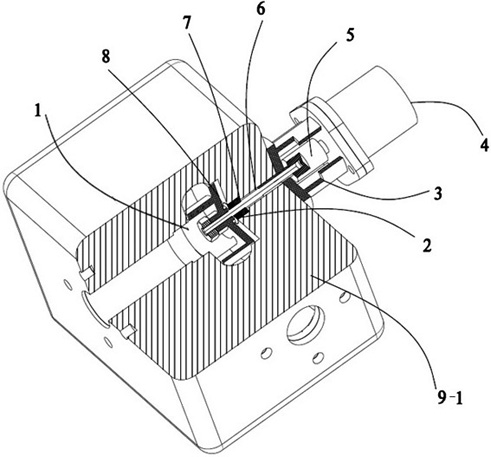

[0033] Embodiment 1 The non-destructive mixing and transporting device for krill provided in this embodiment has an overall structure as follows: figure 1 and 2 As shown, it includes a krill mixing channel 1, a sealing device 2, a motor bracket 3, a motor 4, a coupling 5, a transmission shaft 6, an anti-cavitation impeller 8, a casing 9, and the like.

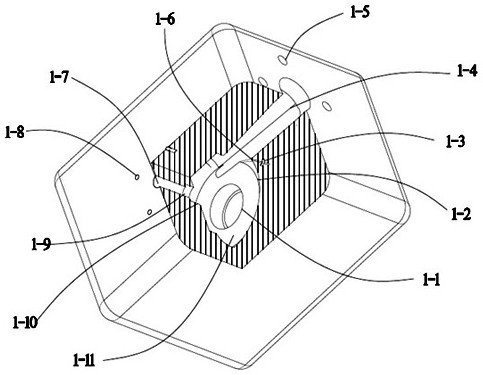

[0034] like figure 2 As shown, in this embodiment, the krill mixing channel 1 is a channel opened inside the solid shell 9-1, and mainly includes an inlet channel 1-1, a main channel 1-11, and an outlet channel 1-4. The inlet flow channel 1-1 and the outlet flow channel 1-4 are in a vertical relationship with the main flow channel 1-11 respectively. As shown in the figure, the main flow channel 1-11 is a hollow structure similar to a volute. The upper end is communicated with the middle of the main channel 1-11, and the inner end of the outlet channel 1-4 is communicated with the outlet of the main channel 1-11, forming a kr...

Embodiment 2

[0046] Embodiment 2 The non-destructive mixing and transporting device for krill provided in this embodiment has an overall structure as follows: figure 1 , 9 As shown in and 10, the structure is basically the same as that of Embodiment 1, including the krill mixing channel, the sealing device 2, the motor bracket 3, the motor 4, the coupling 5, the transmission shaft 6, the anti-cavitation impeller 8, and the casing 9. Wait. The difference is that, in this embodiment, the casing 9 is a hollow casing 9-2, and an end cover 10 is provided above the krill mixing channel.

[0047] The krill mixing channel is a channel arranged inside the hollow shell 9-2, and mainly includes an inlet channel 1-1, a main channel 1-11, and an outlet channel 1-4. The inlet flow channel 1-1 and the outlet flow channel 1-4 are in a spatial vertical relationship with the main flow channel 1-11, such as Figure 10 , 11 As shown, the main flow channel 1-11 is a hollow structure similar to a volute, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com