Real-time monitoring system and method for working state of textile machine

A technology for real-time monitoring system and working status, applied in the textile field, can solve the problems of inability to judge the working status of textile machines, low accuracy of spindle identification, and high labor intensity of material handling, so as to reduce the labor intensity of workers and solve the labor intensity of workers. Large, avoid the effect of handling spindle materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

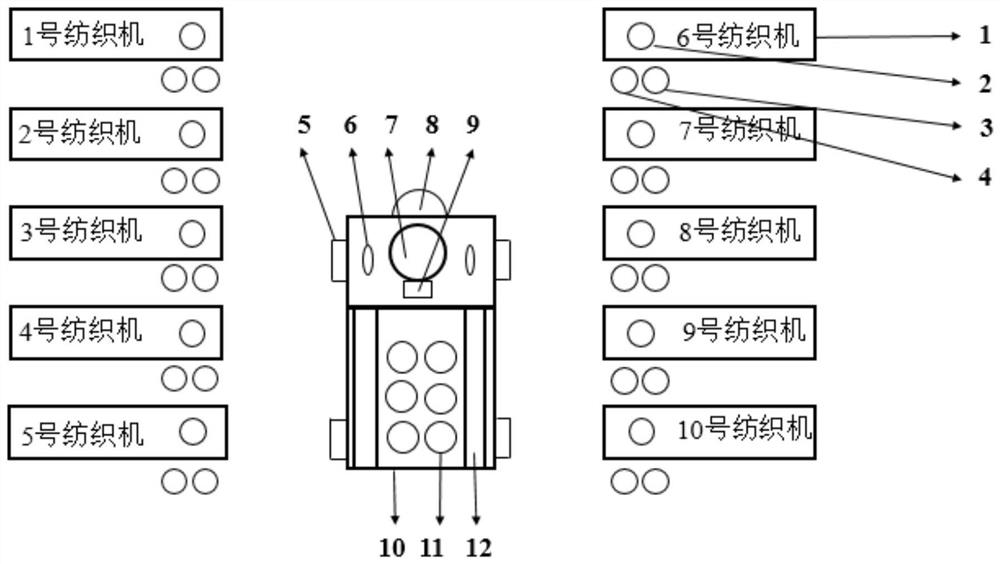

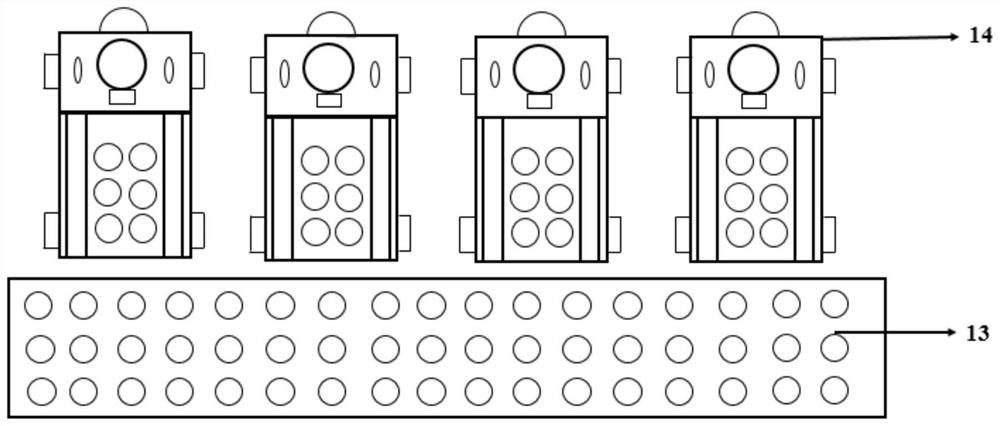

[0041] The present embodiment discloses a real-time monitoring system for the working state of a textile machine, including:

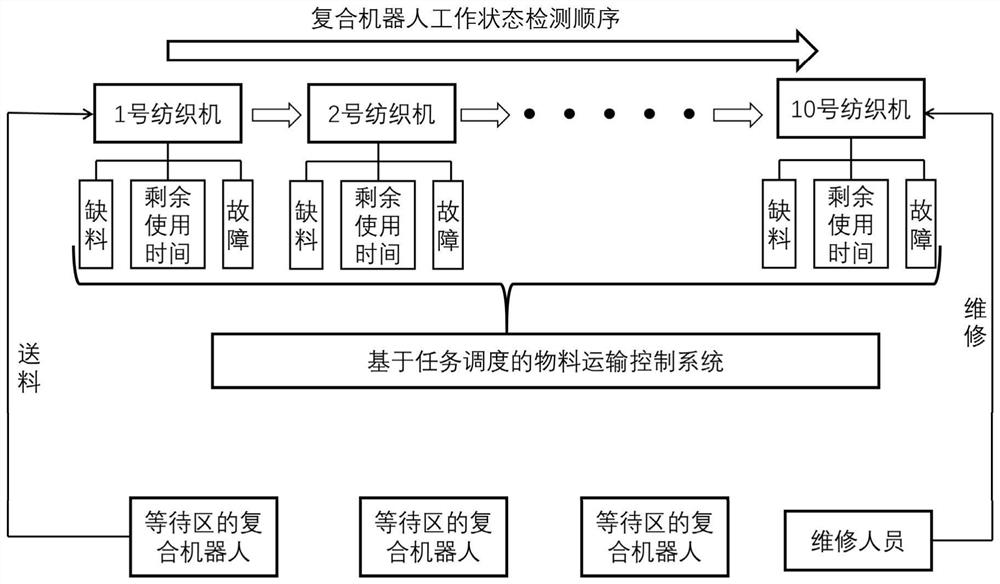

[0042] Composite robot and material transportation control system;

[0043] The composite robot monitors the working state of the textile machine, and when the spindle is in a state of material shortage, the composite robot replaces the short spindle with the full spindle stored by itself;

[0044] After the composite robot has replaced all the full spindles stored by itself, it records and transmits to the material transportation control system whether the next monitored textile machine is short of material, remaining use time, and whether there is a disconnection fault;

[0045] The material transportation control system sorts the feeding tasks of the several textile machines according to the shortage of materials of several textile machines currently monitored by the composite robot, the urgency of the remaining time and the distance of the transpor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com