Groove type alkali polishing and cleaning equipment

A cleaning equipment and trough-type technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as long fixed points, inability to fix, and chip damage, to improve firmness and guarantee. The effect of adsorption stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

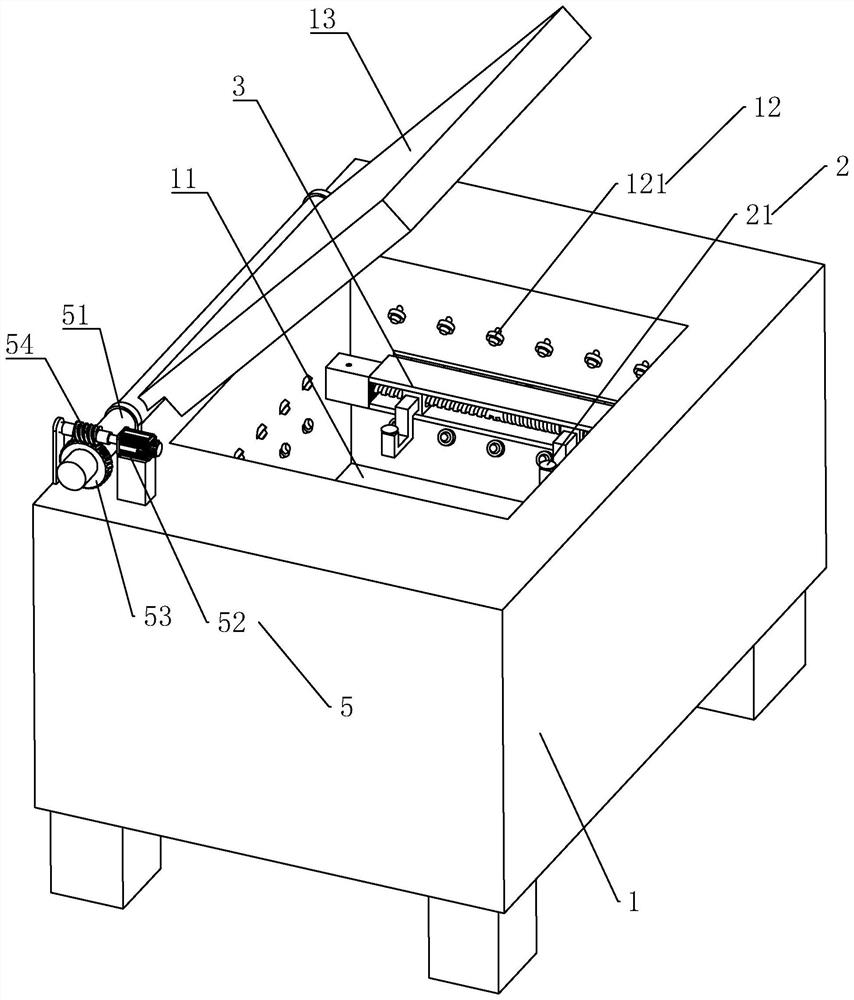

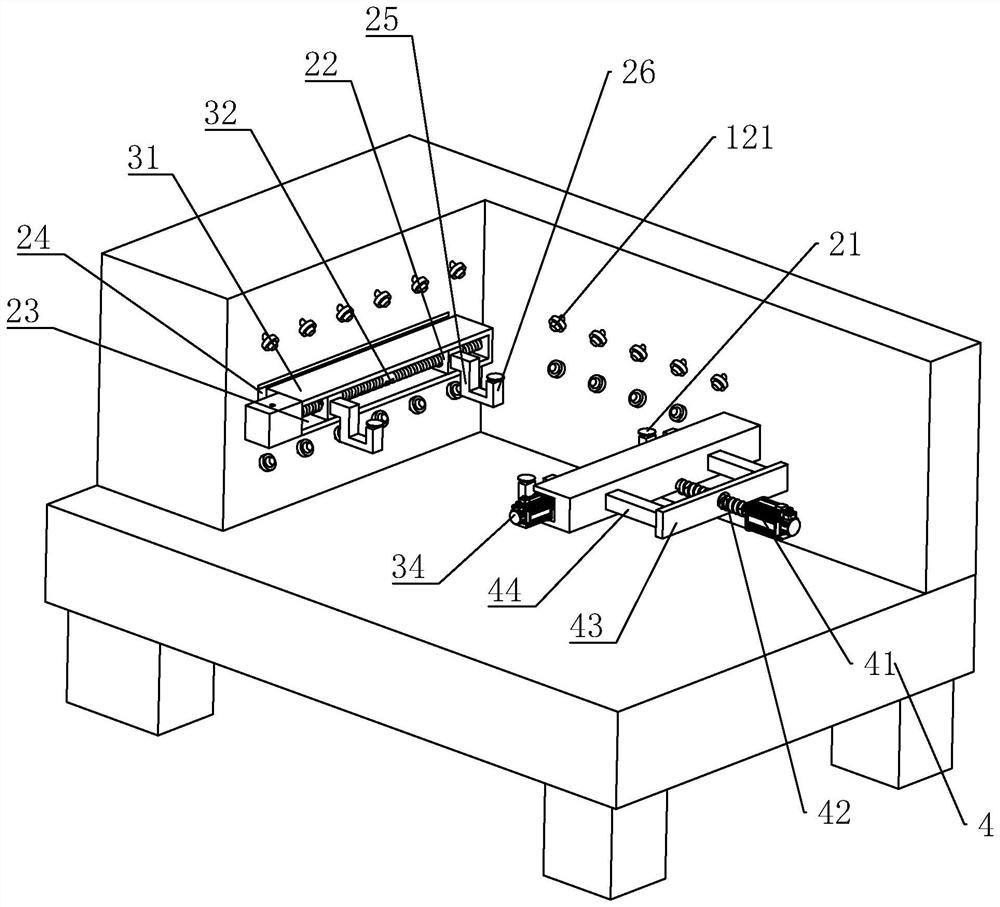

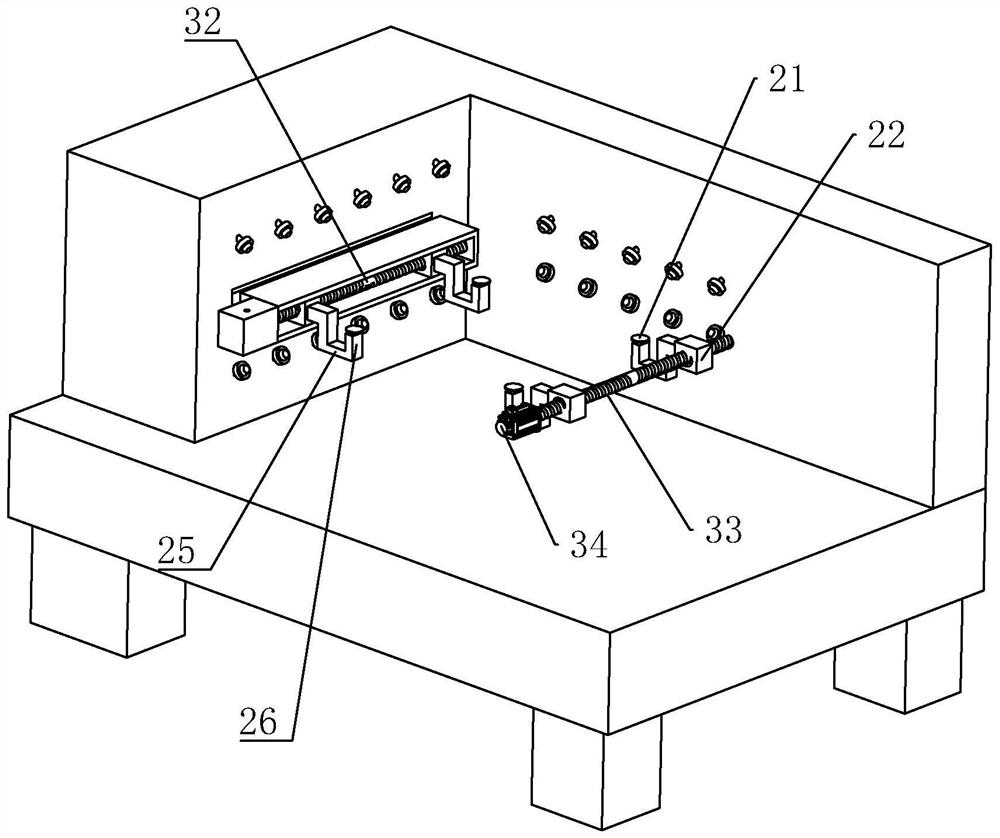

[0027] The present embodiment provides a trough-type alkaline polishing and cleaning equipment, the structure is as follows Figure 1-3 As shown, it includes a body 1, a cleaning tank 11 arranged in the body 1, and a cleaning mechanism 12. The cleaning mechanism 12 includes a number of cleaning heads 121 fixed on the inner sidewall of the cleaning tank 11. The cleaning heads 121 are arranged toward the center of the wafer to clean The heads 121 are provided with two groups, which are respectively fixed at two heights corresponding to the upper and lower sides of the inner side wall of the cleaning tank 11 .

[0028] like Figure 1-3 As shown, the body 1 is provided with a cover plate 13 for closing and opening the cleaning tank 11. The cover plate 13 is rotatably connected to the body 1 through a rotating shaft 51. The size of the cover plate 13 is smaller than that of the cleaning tank 11 to match each other. A rotating member 5 for driving the rotating shaft 51 and the cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com