Stable high-content copper calcium sulfate water suspension preparation

A copper calcium sulfate, water suspension technology, applied in the direction of fungicides, biocides, biocides, etc., can solve the problems of supernatant liquid separation, hard agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

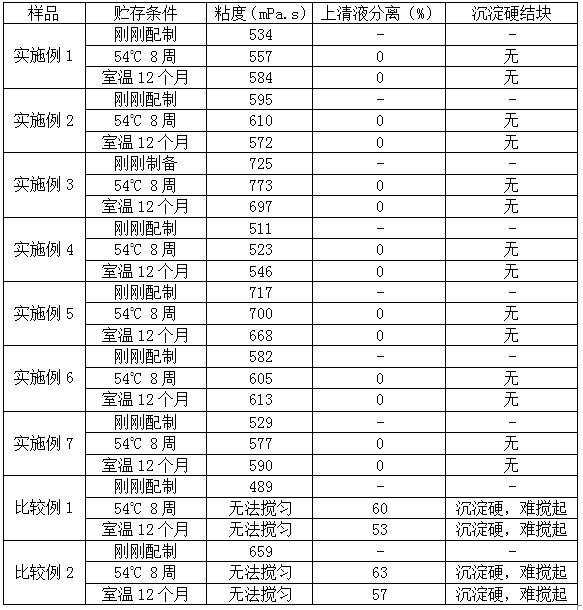

Examples

Embodiment 1

[0041] 1. Dispersion of calcium copper sulfate

[0042] Dispersed in 491.5 g of water were magnesium aluminum silicate [trade name: VEEGUM R, from R.T. VANDERBILT] 7.5 g, lignosulfonate [trade name: POLYFON O, from WESTVACO] 30 g, polyarylphenyl ether ammonium phosphate [trade name: POLYFON O, from WESTVACO] Name: Soprophor FLK, from SOLVAY] 15g, propylene glycol 50g, silicone defoamer [trade name: SAG 1572, Momentive] 2g, in which 660g of copper calcium sulfate (active ingredient concentration 98%) is dispersed, using 0.8-1.2 g The mmφ glass beads were wet-milled with a sand mill [Dynomill®] to obtain 1256 g of a copper-calcium sulfate-containing dispersion.

[0043] 2. Dispersion medium

[0044] In 175.3 g of water were dispersed xanthan gum [trade name: AG-RHO POL 23 / W (CN source, from Solvay] 1.4 g, 1,2-benzisothiazolin-3-one [trade name: CANGUARD ULTRA BIT20, from DOW] 2.5 g, chloromethyl and methylisothiazolinone (trade name: NIPACIDE CI 15 MV, from Clariant) 0.8 g, to...

Embodiment 2

[0048] In Example 1, 175.3 g of water in the dispersion medium was changed to 175.1 g, and 1.4 g of xanthan gum [trade name: AG-RHO POL23 / W (CN source, from Solvay]) was changed to 1.6 g; Manufactured by the same method as Example 1. The average particle size of calcium copper sulfate is controlled to 1.2-1.3um.

Embodiment 3

[0050] In Example 1, 175.3 g of water in the dispersion medium was changed to 174.8 g, and 1.4 g of xanthan gum [trade name: AG-RHO POL23 / W (CN source, from Solvay]) was changed to 1.9 g; Manufactured by the same method as Example 1. The average particle size of calcium copper sulfate is controlled to 1.2-1.3um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com