Movable regeneration device of drying bed

A regeneration device and mobile technology, which are applied in filter regeneration, separation method, combustible gas purification/reconstruction, etc., can solve the problem of not setting dry bed online regeneration circuit, residual radioactive material of dry bed adsorbent, and large radiation protection of adsorbent. Risks and other issues, to achieve the effect of small size, good site adaptability, and low nitrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

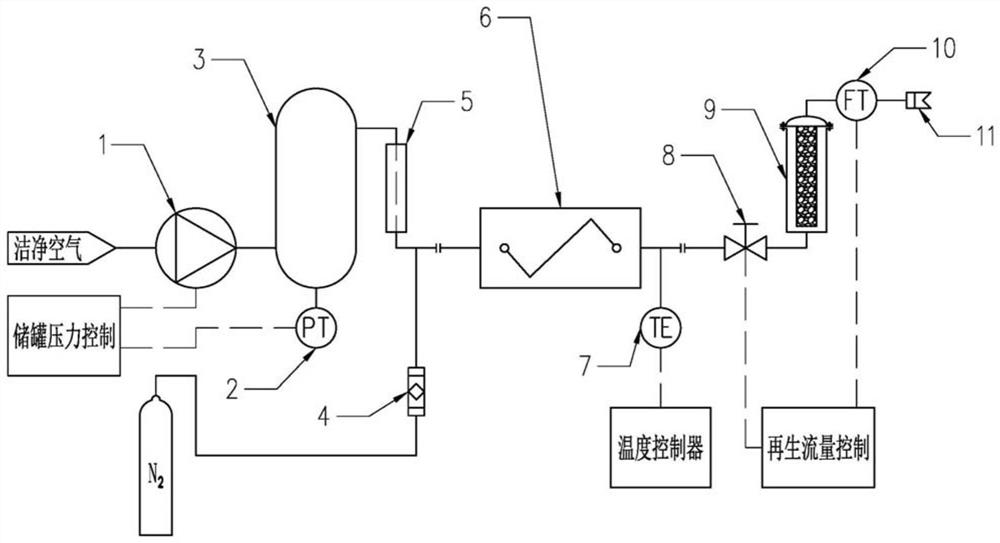

[0022] like figure 1 As shown, the embodiment of the present invention discloses a mobile regeneration device for a drying bed, which includes an air source, a compressed air pump 1, a pressure transmitter 2, an air storage tank 3, a nitrogen source connector 4, a cooling dryer 5, and an electric gas heating 6, temperature transmitter 7, flow control valve 8, silica gel dryer 9, flow transmitter 10, regeneration air outlet 11 and parameter display and control system.

[0023] The air source is connected to a compressed air pump 1, and the compressed air pump 1 is connected to one end of an air storage tank 3. A pressure transmitter 2 is arranged in the air storage tank 3 to measure and control the air pressure in the air storage tank 3. , the other end of the air storage tank 3 is connected with the cooling dryer 5 .

[0024] The nitrogen source is connected to the first end of the gas electric heater 6 through the nitrogen source 4 joint, and the cooling dryer 5 is also conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com