Spherical surface machining method for plunger and special finishing grinder

A spherical surface processing and grinder technology, applied in the field of mechanical processing, can solve the problems of inconsistent axis, spherical surface finish and surface profile quality problems, and achieve the effect of easy replacement, improved processing capacity, market share, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

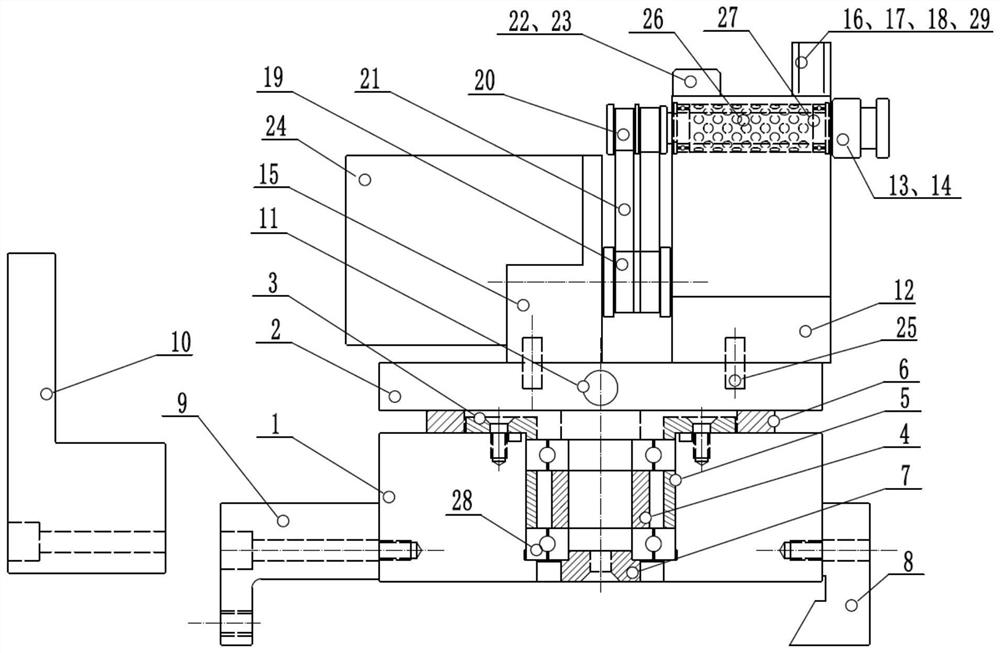

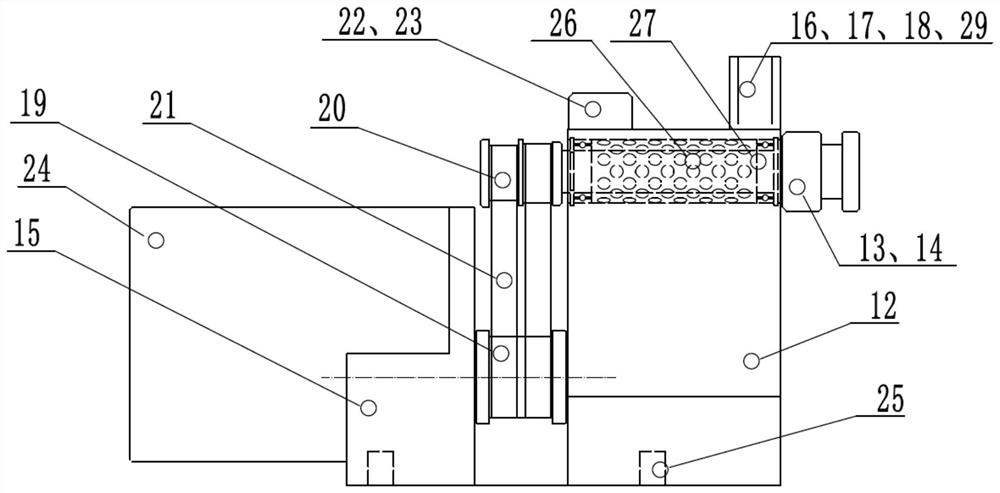

[0046] like figure 1 Shown: A special dressing and grinding machine for the spherical surface processing method of the plunger, including a mechanism composed of a rotary seat group and a double-roller transmission group:

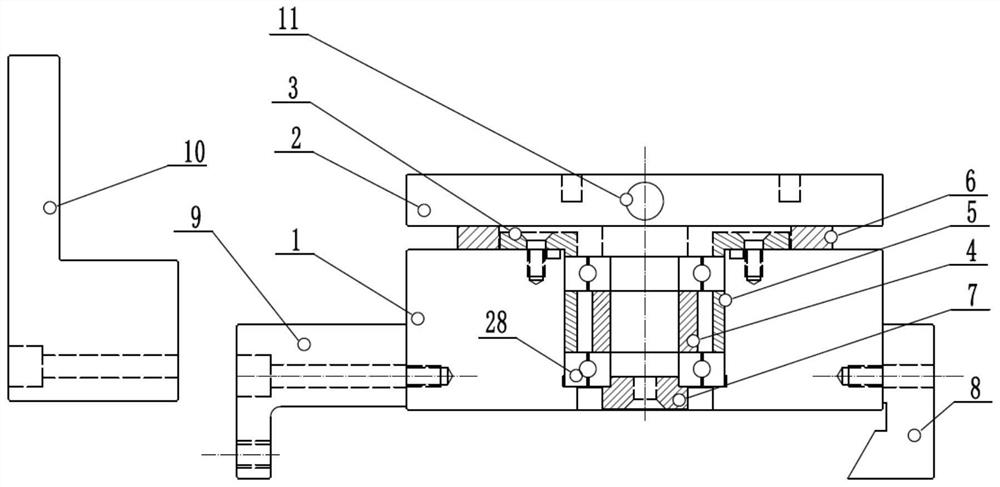

[0047] The structure of the rotary seat group is as follows figure 2 As shown, a pair of radial ball bearings 28 are installed in the shaft hole of the rotary seat 1, the rotary seat shaft inner bushing 4 and the rotary seat shaft outer bushing 5 are installed in the middle of the bearing, and then the rotary seat shaft outer end cover 3 is used to The outer ring of the bearing is fixed tightly, and then the dust-proof sealing ring is installed in the inner hole of the outer end cover of the rotary seat shaft, and the other sealing ring is installed at the other end hole of the rotary seat. Apply lubricating oil on the rotary table liner 6 and put it on the outer end cover of the rotary seat, insert one end of the rotary table 2 shaft from the outer end c...

Embodiment 2

[0054] The object to be processed in this embodiment is a plunger, and the structures of the parts to be processed are as follows Figure 9 , Figure 10 shown.

[0055] A spherical surface processing method of a plunger, firstly, the plunger is processed into a shaft rod structure with a hanging table, the shaft rod is processed into a hollow groove on the inner end face of the hanging table, and then the hanging rod is used as a reference to make the hanging table. The angle and full length of the outer end face of the table are processed, and finally the spherical surface of the outer end of the plunger hanging table is processed on the grinding machine by a special dressing grinder. Specifically include the following steps:

[0056] S1: Centerless grinding machine to process the shaft, the specific steps are:

[0057] 1) The shaft of the plunger is supported by the support plate of the centerless grinder, and the guide wheel drives the workpiece to rotate the grinding wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com