Plastic welding movable arm

A technology of plastic welding and movable arm, applied in the field of thermoplastic materials, can solve the problems of affecting the quality of welding seam, complex welding path, complex shape, etc., and achieve the effect of reducing labor cost, improving welding quality, and improving accuracy and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

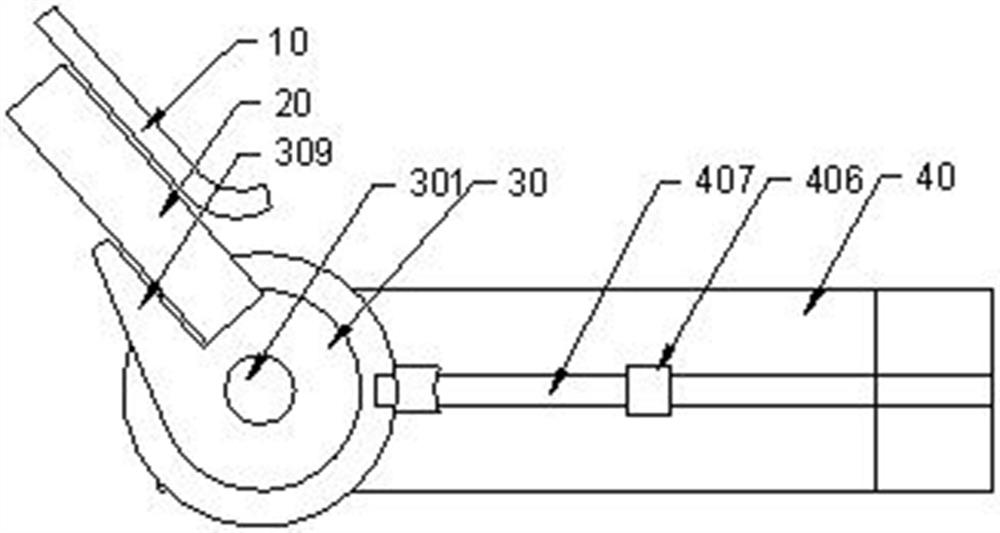

[0053] This embodiment provides a plastic welding movable arm. The working principle of the device is to fix the relative position of the plastic workpiece to be welded and the plastic welding movable arm, and adjust the welding height through the vertical arm assembly 40 according to the welding position to be welded. The welding path is controlled by the travel cart assembly 50 , and the welding angle is adjusted by the flasher assembly 20 .

[0054] The plastic welding movable arm in this embodiment, such as figure 1 As shown, it includes a laser welding gun 10 , a flasher assembly 20 , a swing arm assembly 30 , a vertical arm assembly 40 and a travel car assembly 50 .

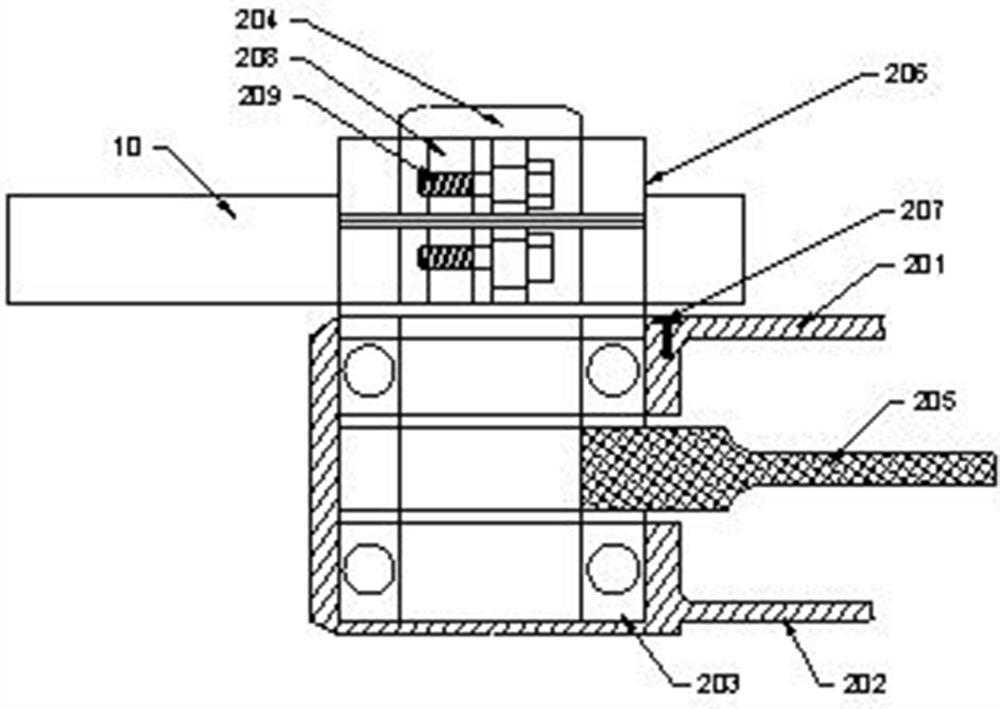

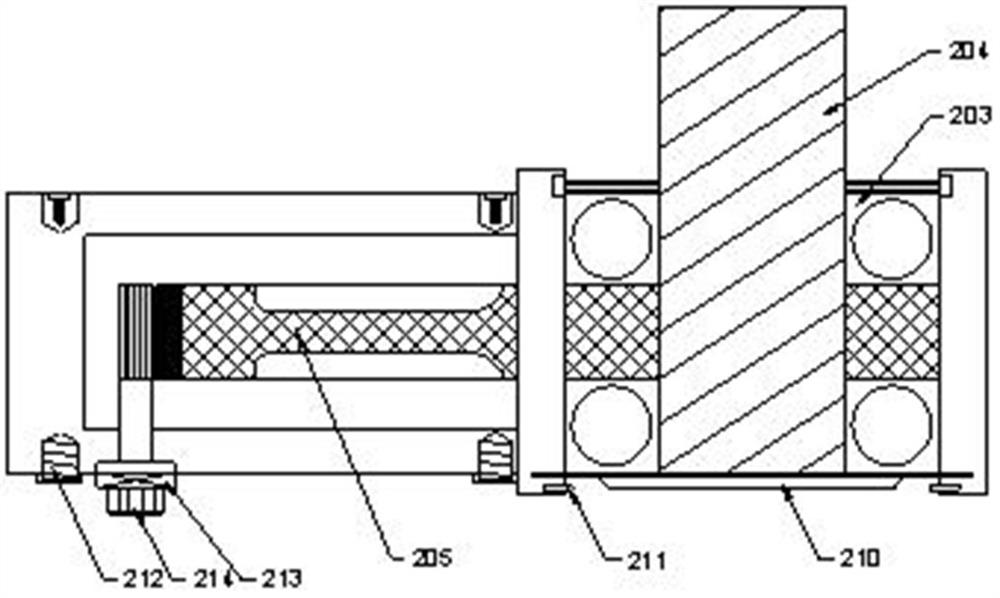

[0055] like Figure 2-4 As shown, the flash oscillator assembly 20 includes a flash oscillator upper shell 201, a flash oscillator bottom shell 202, a flash oscillator bearing 203, a flash oscillator shaft 204, a sector gear 205 and a welding torch bracket 206. The laser welding torch 10 passes through Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com