Modified polyolefin catalyst as well as preparation method and application thereof

A technology of polyolefin catalyst and modifier, applied in the field of modified polyolefin catalyst and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

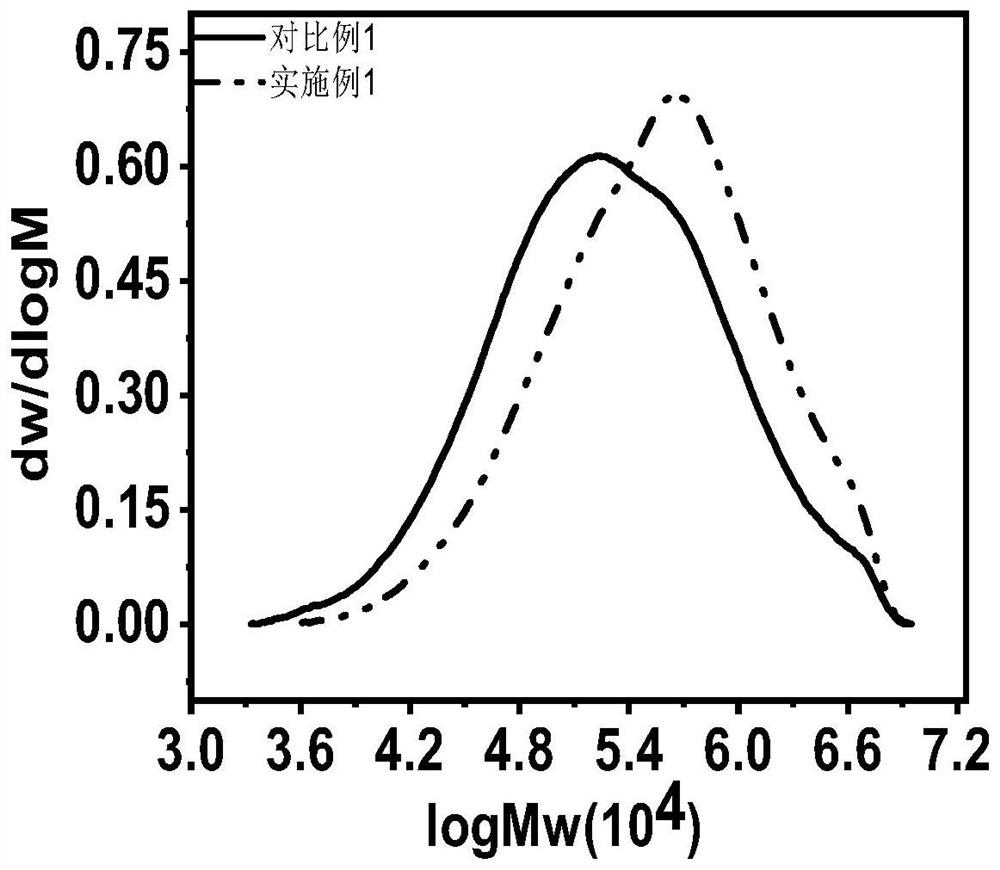

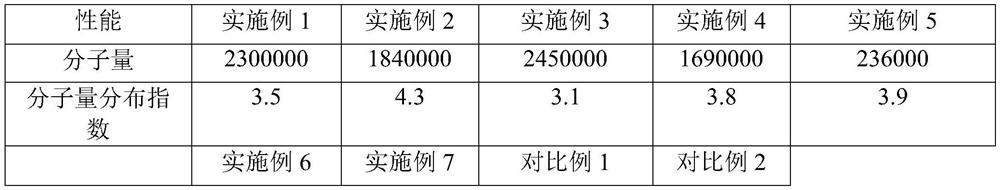

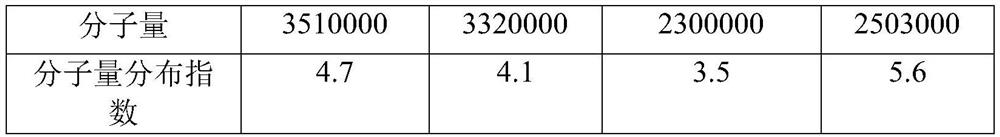

Embodiment 1

[0026] Using MgCl in Comparative Example 1 2 Loaded TiCl 4 Catalyst (Ziegler-Natta catalyst) 1.0g, add 100mL n-hexane, add 0.1g hexamethylcyclotrisiloxane at 30°C, stir for 30min, filter out the supernatant, dry to free flow to obtain modified olefin Polymerization Catalyst A. Take olefin polymerization catalyst A with a Ti molar content of 10 μmol, add 500 mL of n-hexane, raise the temperature to 70 ° C, add 1 mol of triethyl aluminum, feed ethylene to a pressure of 10 bar, and polymerize for 1 h to obtain 310.5 g of polyethylene. GPC After the measurement, the molecular weight of the product was 2303000 g / mol and the molecular weight distribution was 3.5.

Embodiment 2

[0028] Using MgCl in Comparative Example 1 2 Loaded TiCl 4 1.0g catalyst (Ziegler-Natta catalyst), add 100mL n-hexane, add 0.01g cage polysilsesquioxane at 30°C, stir for 30min, filter out the supernatant, dry to free flow, and obtain the modified olefin Polymerization Catalyst B. Take olefin polymerization catalyst B with a Ti molar content of 10 μmol, add 500 mL of n-hexane, raise the temperature to 70 ° C, add 1 mol of triethyl aluminum, feed ethylene to a pressure of 10 bar, and polymerize for 1 h to obtain 152.2 g of polyethylene. After measurement, the molecular weight of the product was 1,840,000 g / mol, and the molecular weight distribution was 4.3.

Embodiment 3

[0030] Using MgCl in Comparative Example 1 2 Loaded TiCl 4 1.0 g of catalyst (Ziegler-Natta catalyst), add 100 mL of n-heptane, add 1.0 g of cage-type polysilsesquioxane at 30°C, stir for 90 min, filter out the supernatant, and dry to free flow to obtain a modified Olefin polymerization catalyst C. Take olefin polymerization catalyst C with a Ti molar content of 10 μmol, add 500 mL of n-heptane, raise the temperature to 70 ° C, add 1 mol of triisobutyl aluminum, feed ethylene to a pressure of 10 bar, and polymerize for 1 h to obtain 127.3 g of polyethylene, After measurement by GPC, the molecular weight of the product was 2,450,000 g / mol, and the molecular weight distribution was 3.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com