Block copolymer electromagnetic shielding composite material with gradient cellular structure and preparation method of block copolymer electromagnetic shielding composite material

A technology of block copolymers and composite materials, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of poor cell gradient and poor cell controllability, avoid secondary pollution, and improve wave absorption. Good performance and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

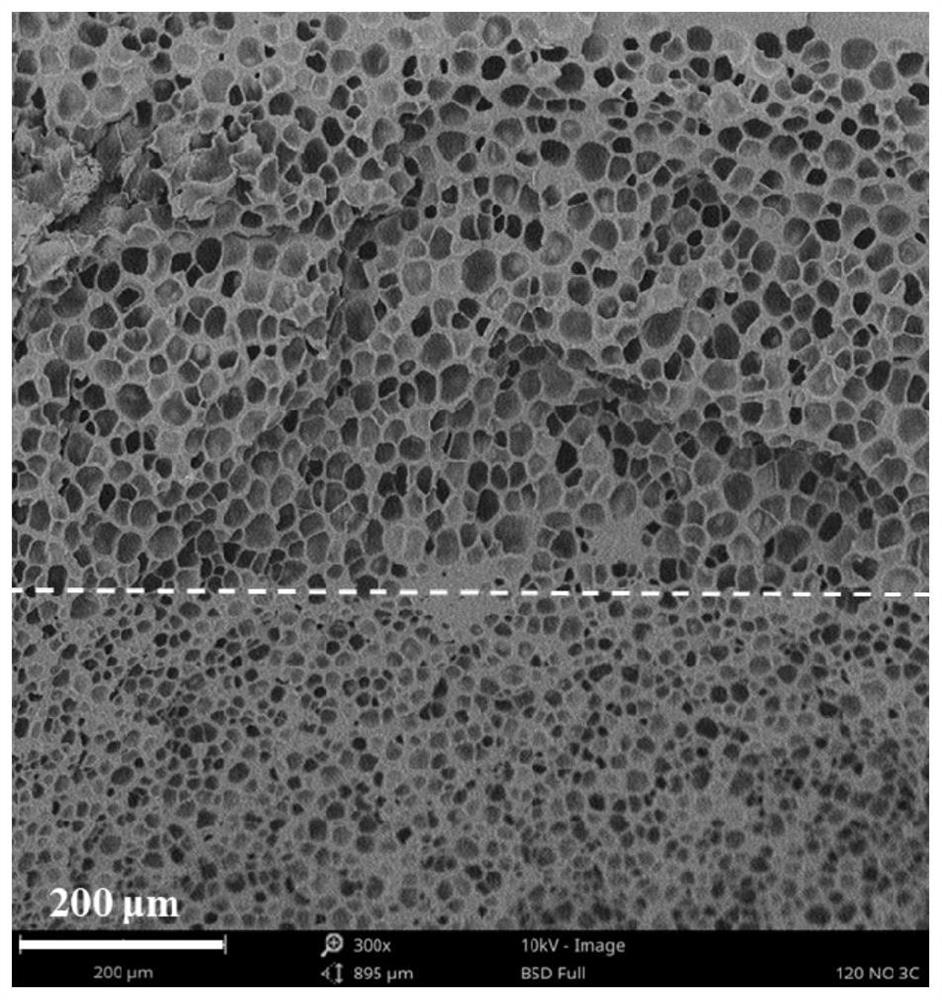

Image

Examples

Embodiment 1

[0038] In this embodiment, the steps of preparing a polyurethane electromagnetic shielding composite material with a gradient cell structure are as follows:

[0039] (1) Preparation of polyurethane / carbon nanotube composite blanks

[0040] Two thermoplastic polyurethanes with the same soft segment and hard segment composition but different ratios of soft segment and hard segment were taken, specifically thermoplastic polyurethanes with hardness of 70A and 80A.

[0041] The thermoplastic polyurethane with a hardness of 70A and carbon nanotubes were added to N,N-dimethylacetamide, and ultrasonicated for 1 h to obtain a blend dispersion. The amount of carbon nanotubes in the blend dispersion was 5% of the quality of the thermoplastic polyurethane. %.

[0042] The thermoplastic polyurethane with a hardness of 80A and carbon nanotubes were added to N,N-dimethylacetamide, and ultrasonicated for 1 h to obtain a blend dispersion. The amount of carbon nanotubes in the blend dispersion...

Embodiment 2

[0049] In the present embodiment, to prepare the polyester amide electromagnetic shielding composite material with gradient cell structure, the steps are as follows:

[0050] (1) Preparation of polyester amide / carbon nanotube composites

[0051] Two polyester amide thermoplastic elastomers with the same soft segment and hard segment composition but different soft segment and hard segment ratio were taken, specifically polyester amide with hardness of 90A and 65D.

[0052] The polyester amide thermoplastic elastomer with a hardness of 90A and carbon nanotubes were added to an internal mixer and blended at 240° C. for 10 minutes. The amount of carbon nanotubes in the blend was 1% of the mass of the polyester amide thermoplastic elastomer.

[0053] The polyester amide thermoplastic elastomer with a hardness of 65D and carbon nanotubes were added to an internal mixer and blended at 270° C. for 10 minutes. The amount of carbon nanotubes in the blend was 5% of the mass of the polyes...

Embodiment 3

[0059] In this embodiment, the steps of preparing a polyurethane electromagnetic shielding composite material with a gradient cell structure are as follows:

[0060] (1) Preparation of polyurethane / carbon nanotube composite blanks

[0061] Three thermoplastic polyurethanes with the same soft segment and hard segment composition but different ratios of soft segment and hard segment were selected, specifically thermoplastic polyurethanes with hardness of 70A, 80A and 90A.

[0062] The thermoplastic polyurethane and carbon nanotubes with a hardness of 70A were added to N,N-dimethylacetamide, and ultrasonicated for 1 h to obtain a blend dispersion. The amount of carbon nanotubes in the blend dispersion was 6% of the mass of the thermoplastic polyurethane. %.

[0063] The thermoplastic polyurethane and carbon nanotubes with a hardness of 80A were added to N,N-dimethylacetamide, and ultrasonicated for 1 h to obtain a blend dispersion. The amount of carbon nanotubes in the blend dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com