600MPa-grade automobile axle housing steel for hot stamping and production method of 600MPa-grade automobile axle housing steel

A production method and hot stamping technology, which is applied in the field of manufacturing steel for automobile axle housings for hot stamping and 600MPa steel for automobile axle housings for hot stamping, which can solve the problems of unsatisfactory, inconsistent, high production costs, etc., and achieve improved strength and toughness, preventing grain growth, and delaying recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

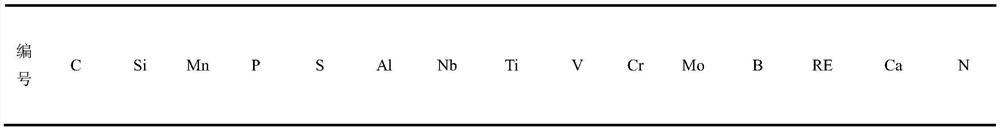

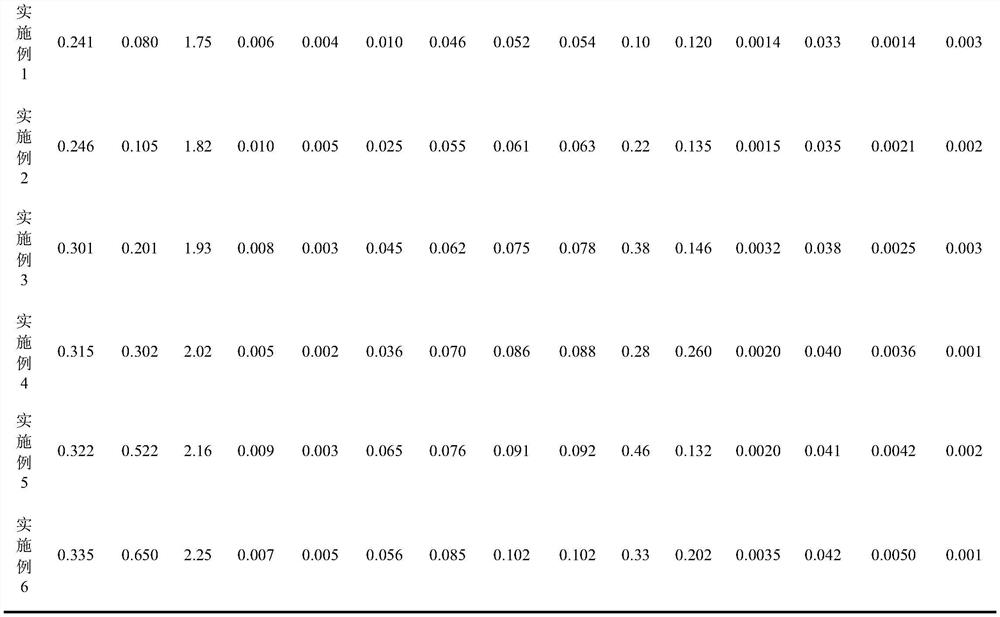

[0046] The present invention will be described in more detail by way of examples, which are only the description of the best mode of implementation of the present invention, and do not limit the scope of the present invention in any way.

[0047] The technological process of heating, rolling and heat treatment of the present invention is as follows:

[0048] The continuous casting slab with thickness of (160-240) mm × (1510-1910) mm is directly hot-loaded into the walking furnace for heating. The furnace gas temperature is high temperature and rapid preheating, the preheating time is 20 ~ 35min, the temperature of heating stage 1 and heating stage 2 are respectively controlled at 1000 ~ 1200 ℃, 1230 ~ 1260 ℃, the total time of heating stage 1 and heating stage 2 is 20 ~25min, temperature of soaking section is 1240~1260℃, soaking time is 110~165min, rough rolling adopts 3+3 mode rolling process, (R1 adopts 3-pass rolling, R2 adopts 3-pass rolling) for a total of 6-pass rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com