Method for bonding polytetrafluoroethylene plate on bottom surface of cable saddle

A technology of PTFE board and bottom surface, which is applied in the direction of construction, bridge construction, bridges, etc., can solve the problems of large volume of cable saddle structure, low bonding strength, and inability of PTFE board, so as to improve thermal bonding quality and improve bonding Quality, compactness and savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

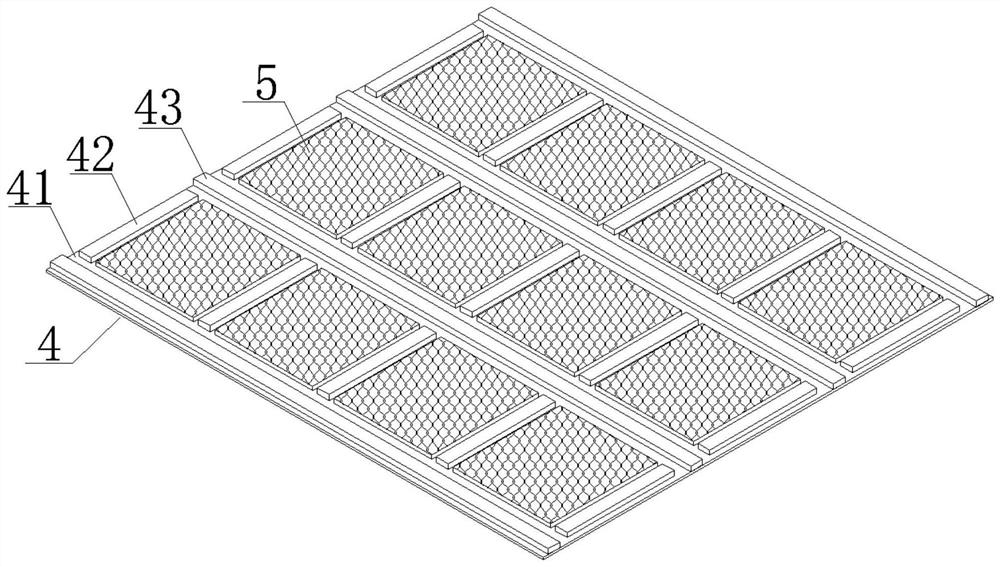

[0057] The structure of the push-pull friction pair tetrafluoro plate at the bottom of the cable saddle is not required by the present invention. The arrangement of the tetrafluoro plate on the bottom surface of the saddle body is not required. For example, each tetrafluoro plate can correspond to the push direction of the saddle body. The longitudinal arrangement structure can also be a fishtail-shaped oblique arrangement structure in which each PTFE plate corresponds to the push direction of the saddle body, and the like.

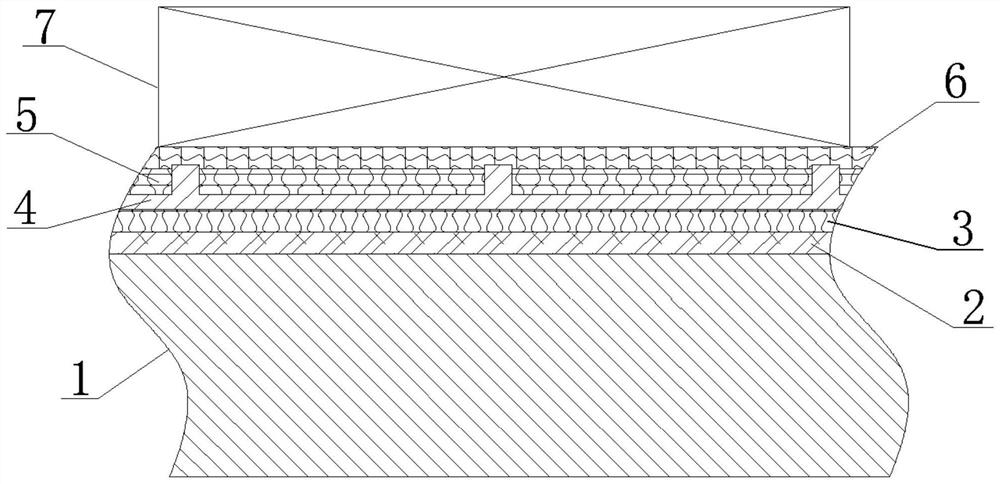

[0058] see figure 1 As shown in the figure, the method of bonding the PTFE plate on the bottom surface of the cable saddle of the present invention (usually refers to the main cable saddle of the suspension bridge; of course, it is applicable to any cable saddle that involves the jacking operation and needs to form a PTFE plate at the bottom). The method specifically includes the following process steps:

[0059] Step 1. Place the saddle body 1 with the ...

Embodiment 2

[0088] The method for bonding the tetrafluoro board on the bottom surface of the cable saddle of the present invention specifically comprises the following process steps:

[0089] Step 1. Place the saddle with the bottom side up to facilitate the bonding operation;

[0090] According to the PTFE plate arrangement structure required by the design of the saddle bottom surface, mark the area on the bottom surface of the saddle body that currently needs to be bonded to the PTFE plate;

[0091] Use organic solvent - such as acetone, to clean the bottom surface of the current bonding area of the saddle body, and remove the sundries and oil stains attached to the current bonding area of the saddle body bottom surface; after the current bonding area of the saddle body bottom surface is cleaned, wait until it is completely dry ;

[0092] Clean the sodium naphthalene surface of the current tetrafluoro board and wait for it to dry completely;

[0093] Step 2. Apply the AB glue ev...

Embodiment 3

[0118] The method for bonding the tetrafluoro board on the bottom surface of the cable saddle of the present invention specifically comprises the following process steps:

[0119] Step 1. Place the saddle with the bottom side up to facilitate the bonding operation;

[0120] According to the PTFE plate arrangement structure required by the design of the saddle bottom surface, mark the area on the bottom surface of the saddle body that currently needs to be bonded to the PTFE plate;

[0121] Use organic solvent - such as acetone, to clean the bottom surface of the current bonding area of the saddle body, and remove the sundries and oil stains attached to the current bonding area of the saddle body bottom surface; after the current bonding area of the saddle body bottom surface is cleaned, wait until it is completely dry ;

[0122] Clean the sodium naphthalene surface of the current tetrafluoro board and wait for it to dry completely;

[0123] Step 2. Apply the AB glue ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com