Two-parameter in-situ sensor based on waveguide grating, sensing system and preparation method

An in-situ sensor and waveguide grating technology, applied in the field of sensing, can solve the problems of difficulty in meeting acoustic signal measurement requirements, low Fabry-Perot cavity fineness, poor sensing sensitivity, etc., so as to avoid cross-coupling of two parameters. problems, eliminate high temperature stress mismatch, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

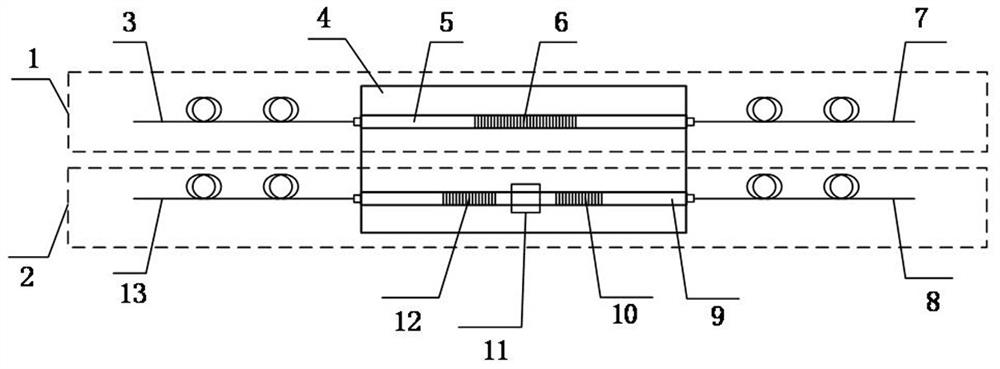

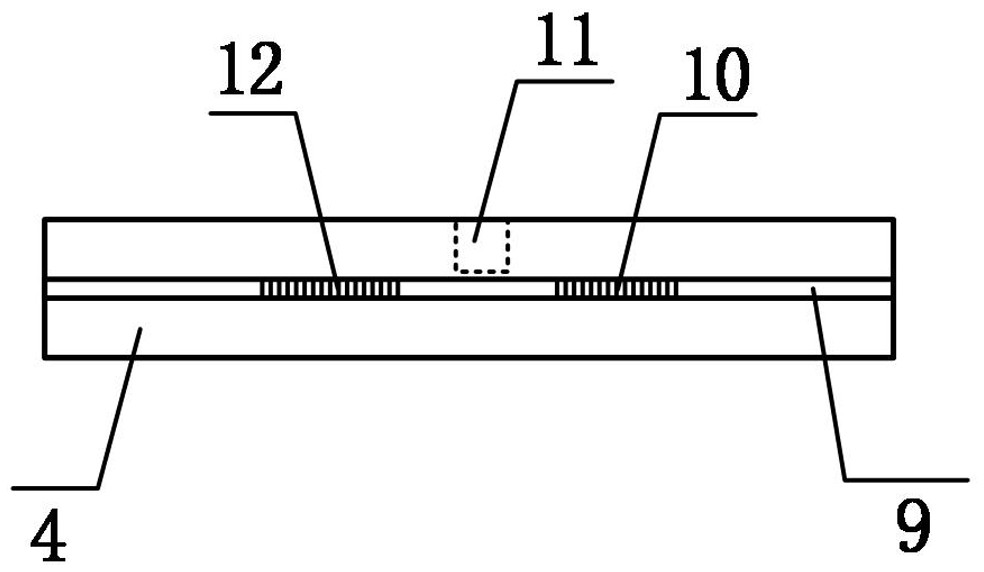

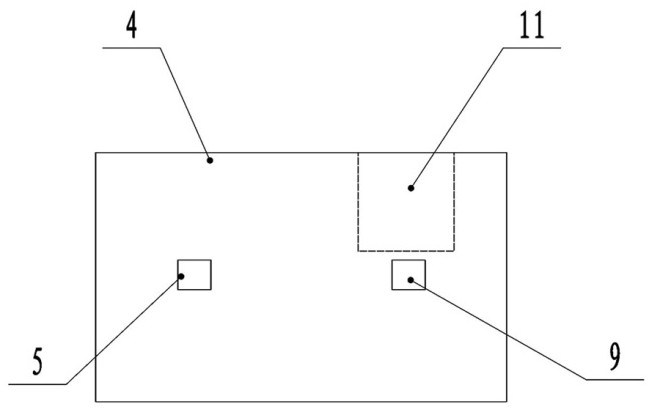

[0040] like Figures 1~3 As shown, Embodiment 1 of the present invention provides a dual-parameter in-situ sensor based on a waveguide grating, comprising: an optical waveguide substrate 4, wherein a first straight optical waveguide 5 and a second straight optical waveguide are arranged in parallel in the optical waveguide substrate 4 Two straight optical waveguides 9, two ends of the first straight optical waveguide 5 are respectively connected to the first transmission fiber 3 and the second transmission optical fiber 7, and both ends of the second straight optical waveguide 9 are respectively connected to the third transmission fiber 8 is connected to the fourth transmission fiber 13, the first straight optical waveguide 5 is provided with a first Bragg grating 6, and the second straight optical waveguide 9 is separately provided with a second Bragg grating 10 and a third Bragg grating 12. A micro air groove 11 is provided on the upper surface of the optical waveguide subst...

Embodiment 2

[0051] like Figure 8 As shown, the second embodiment of the present invention provides a dual-parameter sensing system based on a waveguide grating, including a light source 19, a first spectrometer 20, a second spectrometer 21, a signal processor 22, and the waveguide grating-based one of the first embodiment. The dual parameter in situ sensor 23 . The light source 19 is used to provide optical signals to the first transmission optical fiber 3 and the fourth transmission optical fiber 13, and the first spectrometer 20 is used to receive the optical signal output by the second transmission optical fiber 7, and obtain a first spectrum; The second spectrometer 21 is respectively used to receive the optical signal output by the third transmission fiber 8, and obtain the second spectrum; the signal processor 22 is used to calculate and obtain the temperature signal according to the first spectrum, and to obtain the temperature signal according to the The second spectrum is descr...

Embodiment 3

[0053] like Figure 9 As shown, Embodiment 3 of the present invention provides a method for preparing a dual-parameter in-situ sensor based on a waveguide grating, which is used to prepare the dual-parameter in-situ sensor based on a waveguide grating, including the following steps:

[0054] S1, grow silicon dioxide 17 on the silicon substrate to form the silicon dioxide layer 14, and grow germanium-doped silicon dioxide on the silicon dioxide layer 14 to form the germanium-doped silicon dioxide layer 15, such as Figure 9 shown in (a).

[0055] Specifically, in the step S1, the thickness of the silicon dioxide layer 14 is 15±3 μm, and the thickness of the germanium-doped silicon dioxide layer 15 is 6.5±2 μm. After the growth is completed, the entire structure is annealed at a high temperature at a temperature of 900° C. to 1100° C. for 35 hours.

[0056] S2. Set a mask 18 on the germanium-doped silicon dioxide layer 15, etch away excess germanium-doped silicon dioxide by re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com