Load monitoring device and method for buffeting test of airplane key structure

A monitoring device and loading device technology, which is applied in the testing of machines/structural components, measuring devices, and aircraft component testing, etc., can solve problems such as damage to test pieces, deviation of loading values, and damage to test pieces, and achieve simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

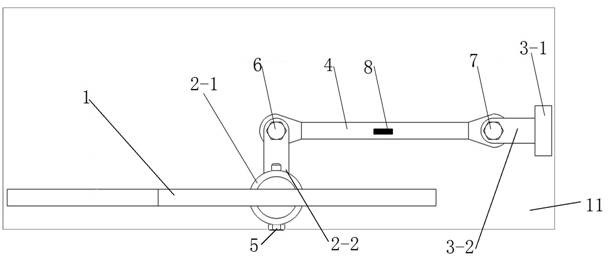

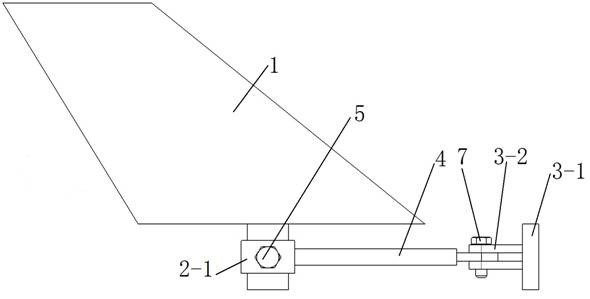

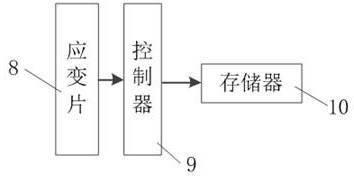

[0029] like figure 1 , figure 2 and image 3 The shown load monitoring device for the buffeting test of key structures of an aircraft includes an aircraft vertical tail test piece 1 vertically arranged on a test bench 11, a load transmission structure arranged at the bottom of the aircraft vertical tail test piece 1, and a connection a load monitoring structure on the load transmission structure;

[0030] The load transmission structure includes a mounting seat vertically arranged at the bottom of the vertical tail test piece 1 of the aircraft, a fixing seat arranged on the test stand 11, and a horizontal connection between the mounting seat and the fixing seat Rod 4; the bottom of the aircraft vertical tail test piece 1 is inserted into the mounting seat, and the mounting seat is connected with the aircraft vertical tail test piece 1 through bolts 5; the mounting seat and one end of the connecting rod 4 Connected by a first connecting pin 6, and the other end of the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com