Method for detecting effluent rate of slag steel type waste steel by adopting intermediate frequency furnace

A technology of water yield and intermediate frequency furnace, applied in furnace types, furnaces, electric furnaces, etc., can solve the problems of poor representation, large influence of usage, poor quality stability, etc., to improve the quality of scrap steel, avoid adulteration, and reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

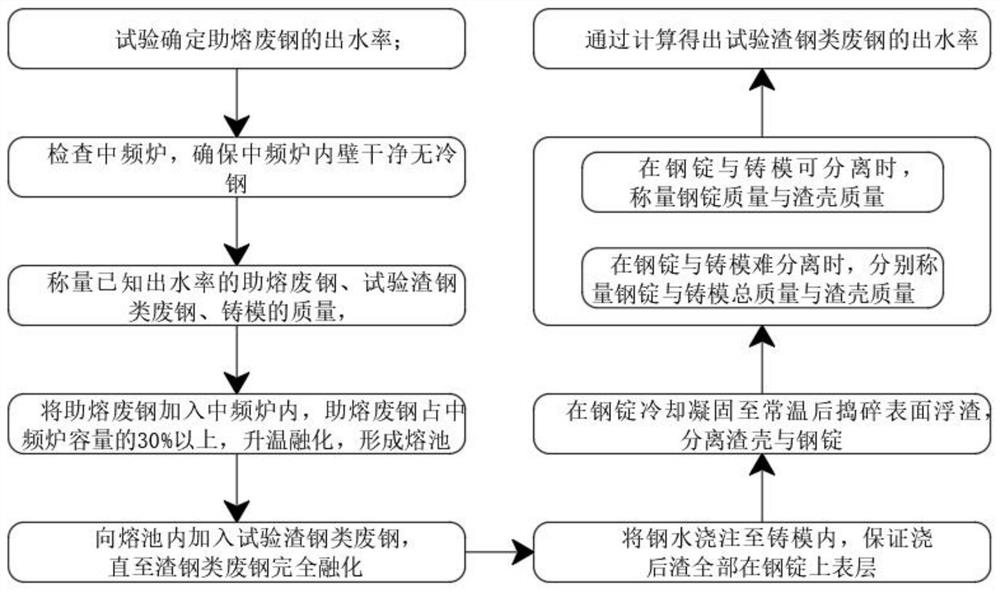

Method used

Image

Examples

Embodiment 1

[0036] 1) The residual sample of the impact test is used as fluxing scrap, the average water yield is 98.73%, and the test scrap is slag steel;

[0037] 2) According to the experimental design, weigh the raw materials and the quality of the casting mold, the fluxing scrap is 60.4kg, the slag steel is 80.7kg, and the casting mold quality is 364.6kg;

[0038] 3) After melting, pouring, and slag steel separation, after the steel ingot is separated from the casting mold, the net mass of the steel ingot is 123.8kg, and the slag mass is 22.2kg;

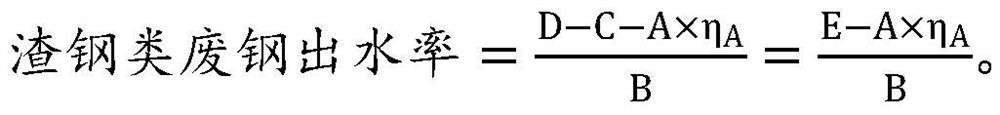

[0039] 4) The water yield of the test scrap steel is:

Embodiment 2

[0041] 1) The residual sample of the impact test is used as fluxing scrap, the average water yield is 98.73%, and the test scrap is slag steel;

[0042] 2) According to the experimental design, weigh the quality of the raw materials and the casting mold, the fluxing scrap steel is 70.6kg, the slag steel is 76.8kg, and the casting mold quality is 69.8kg;

[0043] 3) After melting, pouring and slag steel separation, the ingot and the casting mold cannot be separated (the casting mold is one-time), and the total mass of the steel ingot and the casting mold is 202.2kg, and the slag mass is 18.8kg;

[0044] 4) The water yield of the test scrap steel is:

Embodiment 3

[0046] 1) The residual sample of the impact test is used as fluxing scrap, the average water yield is 98.73%, and the test scrap is small slag steel;

[0047] 2) According to the experimental design, weigh the quality of the raw materials and the casting mold, the fluxing scrap steel is 105.8kg, the small slag steel is 40.4kg, and the casting mold quality is 70.2kg;

[0048] 3) After melting, pouring, and slag steel separation, the ingot and the casting mold cannot be separated (the casting mold is one-time), and the total mass of the steel ingot and the casting mold is 201.6kg, and the slag mass is 17.2kg;

[0049] 4) The water yield of the test scrap steel is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com