Self-coupling wire connector adopting bending compression and conducting strip bending modes

A conductive sheet and self-coupling technology, applied in the direction of conductive connection, coupling device, electrical component connection, etc., can solve the problems of reducing the reliability of wire connection, incapable of internal decomposition of pressure, increasing the requirements of manufacturing materials, etc., to achieve the effect of strengthening self-coupling , the effect of improving the degree of mutual restriction, reducing the cost and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

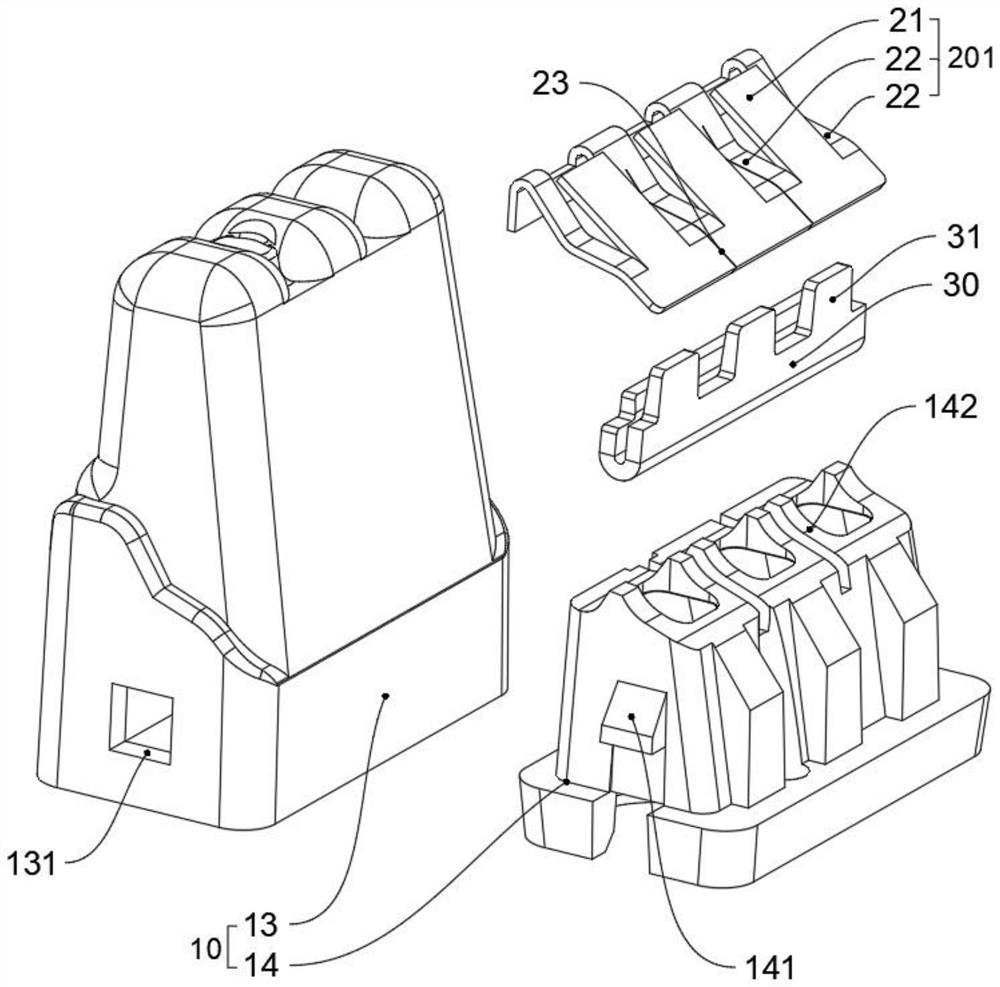

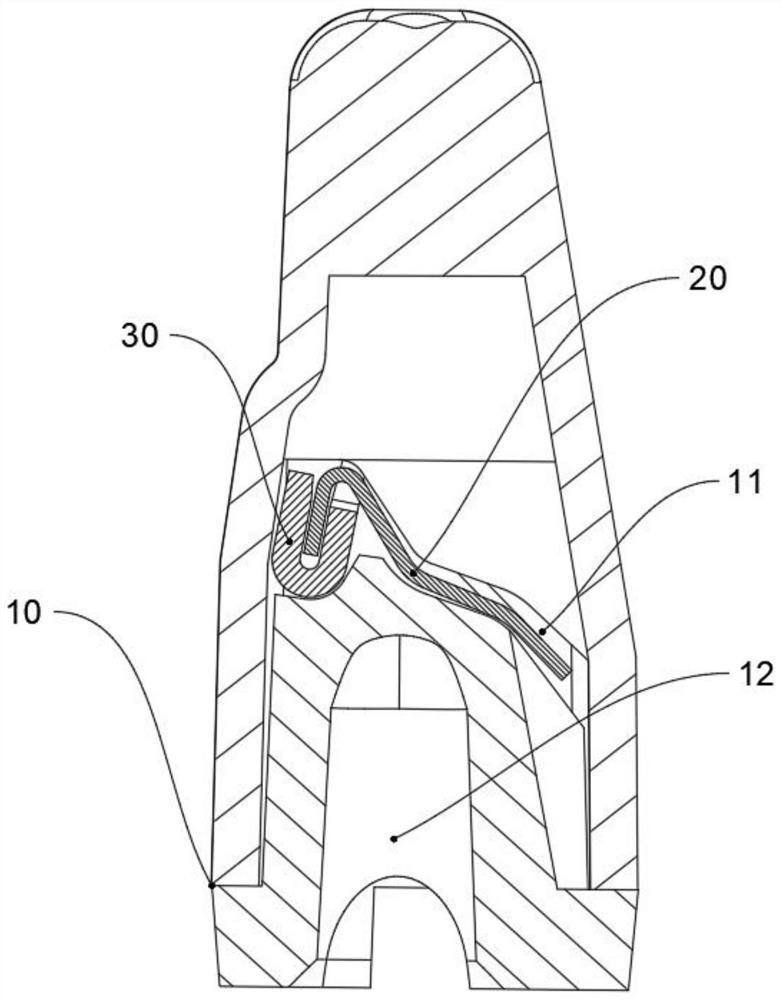

[0071] see Figure 1 to Figure 5 , set the wire crimping units 201 on the elastic sheet 20 into a plurality, and set the plurality of wire crimping units 201 as a horizontal connection structure. The design, taking three wire insertion holes 12 as an example, can satisfy a wire connector with an odd number of wire insertion holes 12. Specifically, a plurality of wire pressing units 201 are arranged in a row, and two adjacent wire pressing units 201 are deformed by one of them. In addition, the elastic sheet 20 is arranged to leave a first assembly gap 24 between the planes after the third bending angle 223 of each deformation portion 22 is bent, and the conductive sheet 30 is along the The middle part is bent so that a second assembly gap 34 is left between the bent planes of the conductive sheet 30; the conductive sheet 30 is inserted into the first assembly gap 24 through the end corresponding to the toothed structure 31, and the teeth on the The number of teeth corresponds...

Embodiment 2

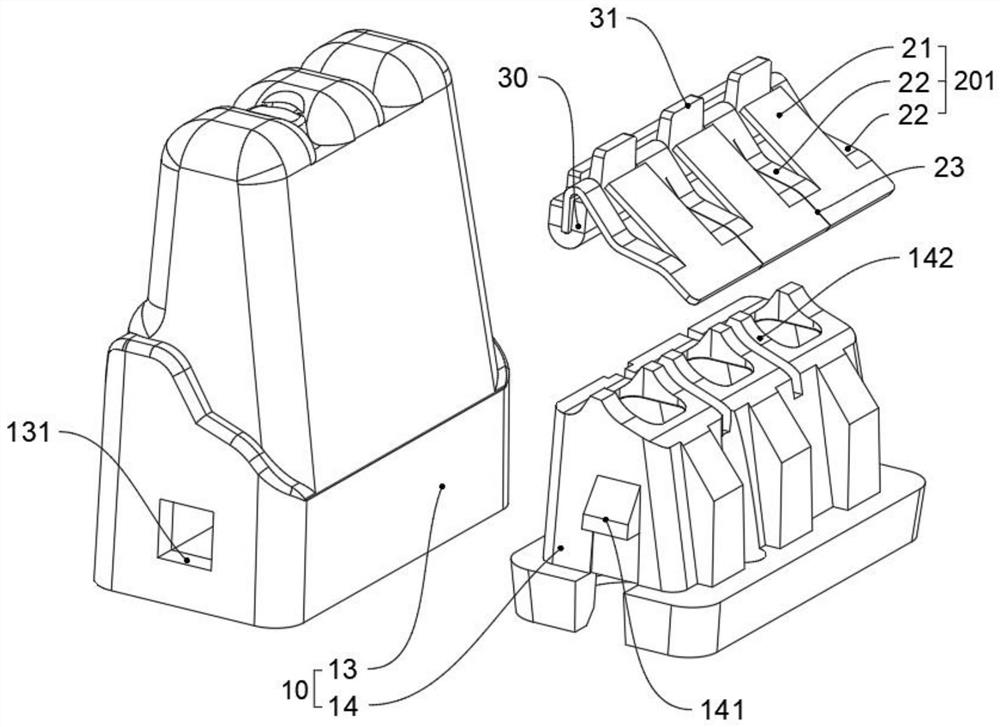

[0073] see Figure 6 to Figure 10 , the wire pressing units 201 on the elastic sheet 20 are arranged in multiples, and the plurality of wire pressing units 201 are arranged in a double-row arrangement structure, and the two rows of wire pressing units 201 are arranged in a vertical connection structure. The unit 201 is set as a horizontal connection structure, and the third bending angle 223 of the deformation part 22 is bent to form a vertical connection surface, and the two vertically adjacent pressing line units 201 are combined through the vertical connection surface, so that the adjacent two A third assembly gap 25 is left between the bent planes of the third bending corners 223 of the deformed portions 22 of each of the crimping units 201 ; An arc protruding portion extends toward the side of the pressing portion 21, and each arc protruding portion is bent inward to form the supporting surface 26 of the bent inner corner of the conductive sheet 30; the conductive sheet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com