Hydraulic buffering heavy-load electric cylinder based on disc spring compression and buffering control method

A technology of hydraulic buffer and electric cylinder, which is applied in the direction of electric components, control of mechanical energy, vibration suppression and adjustment, etc., can solve the problems of unable to protect mechanical parts such as screw transmission pairs, time lag of sensors and controllers, and low reliability, etc., to achieve Improve reliability and service life, occupy less space, increase lubrication and reduce friction bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

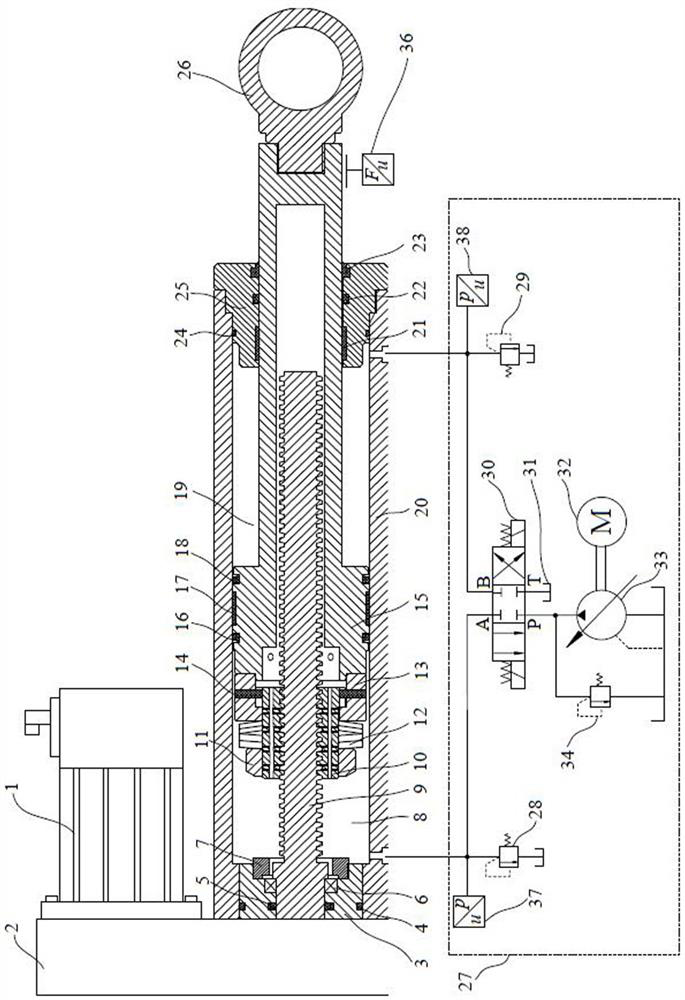

[0038] as attached figure 1 As shown, a hydraulic buffer heavy-duty electric cylinder based on disc spring compression includes a servo motor 1, a reducer 2, a trapezoidal screw pair, a disc spring compression mechanism, a push rod 15, a cylinder barrel 20, a cylinder head 25, and a hydraulic system. 27.

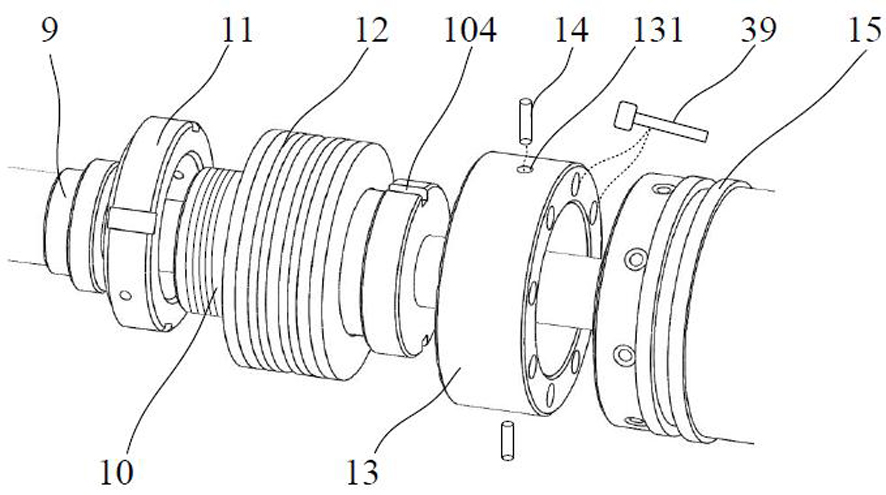

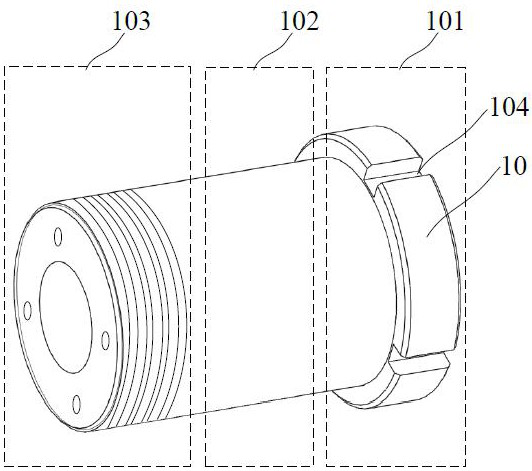

[0039] The trapezoidal lead screw pair includes a lead screw 9 and a nut 10 that cooperate with each other. The lead screw pair can also be replaced with either a ball screw pair or a planetary roller screw pair.

[0040] The servo motor 1 is connected with the lead screw 9 through the reducer 2, and the rotational motion of the servo motor 1 is transmitted to the lead screw 9 through the action of deceleration and torque increase. 10 linear motion.

[0041] The disc spring compression mechanism includes a disc spring pre-compression adjusting nut 11 , a disc spring group 12 and a connecting sliding sleeve 13 . The disc spring group 12 is between the connecting sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com