Rapid unloading device for petroleum asphalt tank container

A technology of tank container and unloading device, which is applied in the direction of cleaning device, loading/unloading, packaging, etc. It can solve the problems of difficult cleaning of equipment, uncontrollable temperature, large dust and impurities, etc., and achieve the effect of speeding up the water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

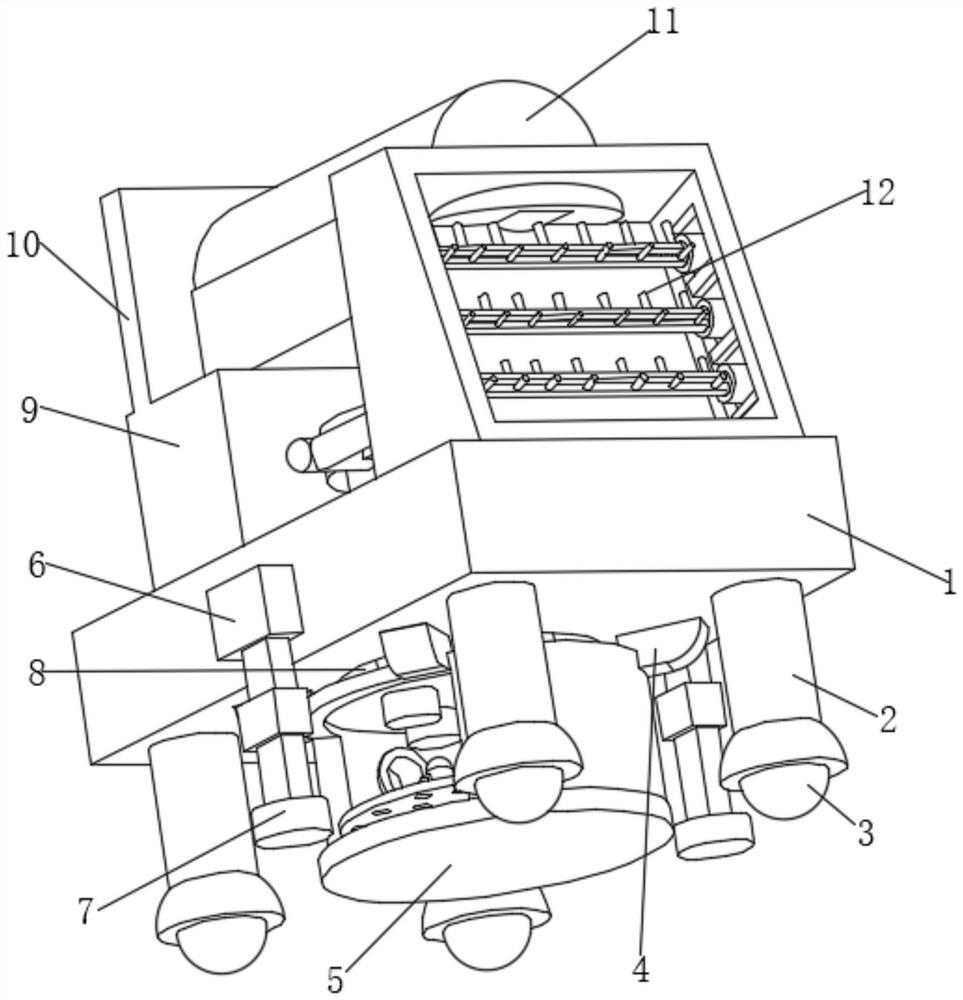

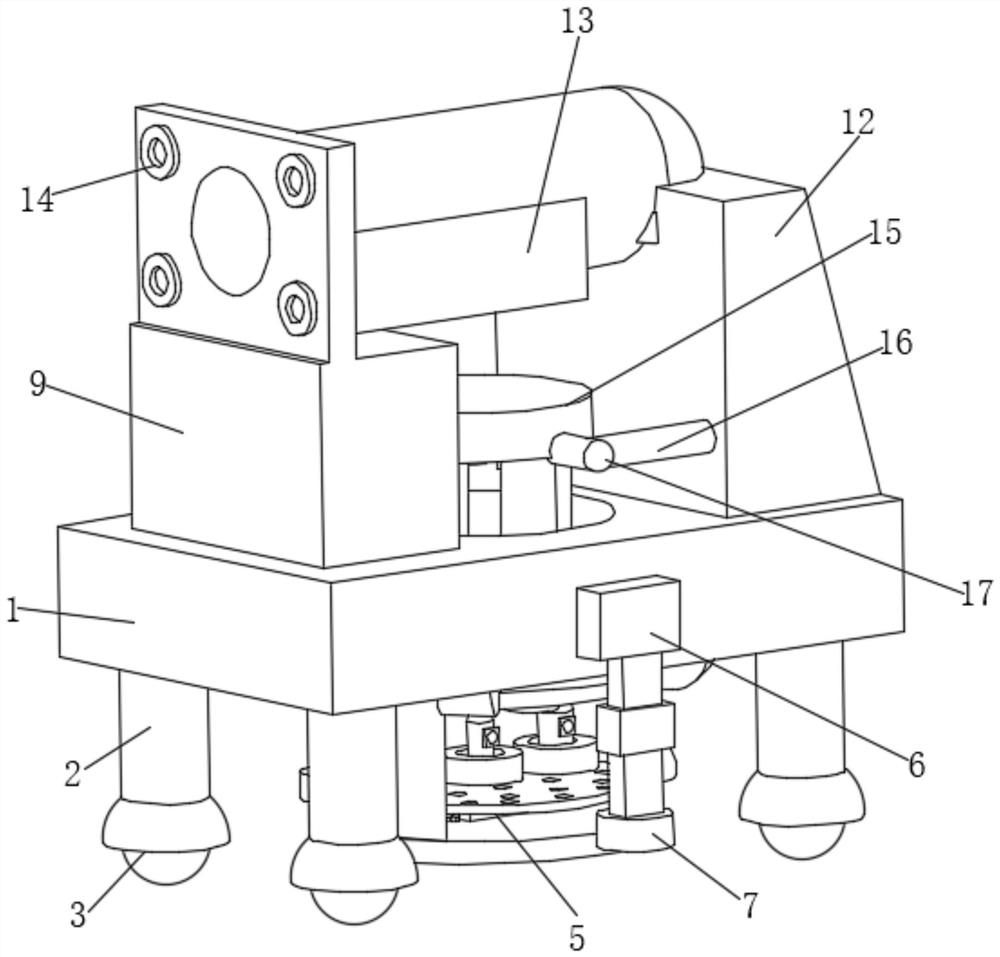

[0035] Example one, as Figure 1-Figure 2 As shown, the present invention provides a technical solution: specifically including:

[0036] A fixed table 1, the fixed table 1 has a stable base, and a control column 2 arranged under the fixed table 1, a roller 3 is arranged below the control column 2, and a connecting assembly 4 is fixedly connected to the bottom of the fixed table 1. A filter water tank 5 is fixedly connected in the middle, a reinforcement block 6 is fixedly connected to the outside of the fixing table 1, a telescopic fixing column 7 is fixedly connected under the reinforcement block 6, and a hollow slot 8 is opened in the middle of the fixing table 1;

[0037] The support table 9, the support table 9 has a height adjustment base, and a connecting plate 10 arranged above the support table 9, a transportation channel 11 is fixedly connected from the right side of the 10, and a connecting channel 12 is fixedly connected below the transportation channel 11. A heat...

Embodiment 2

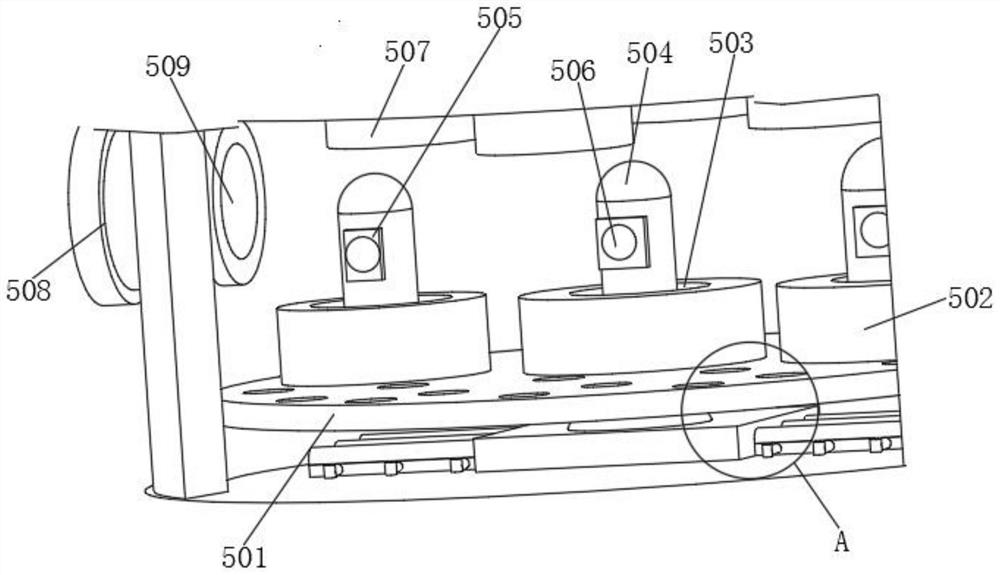

[0040] Example two, as image 3 As shown, the rotating circular plate 501 has an adhesive lower plate and a fixed heating mechanism A arranged below the rotating circular plate 501. The interior of the rotating circular plate 501 is provided with a circulation hole, and the upper part of the rotating circular plate 501 is provided There is a fixed protective box 502, and a fixed groove 503 is opened in the middle of the fixed protective box 502;

[0041] The rotating column 504 has a smooth upper top and a connecting table 505 arranged in the middle of the rotating column 504. The connecting table 505 has an adsorption column 506 running through it, and a suction fixing pipe 507 is arranged above the inside of the filtered water tank 5. The left side of the filtered water tank 5 is provided with a feeding tray 508 , and the inside of the filtered water tank 5 is provided with a feeding socket 509 .

[0042] The suction fixing tube 507 is fixedly connected to the buffer groove...

Embodiment 3

[0043] Example three, as Figure 4 As shown, a push-pull plate 1101 is arranged inside the transport channel 11, a spring telescopic column 1102 is fixedly connected to the right side of the push-pull plate 1101, a heating water tank 1103 is fixedly connected to the right side of the spring telescopic column 1102, and a heating water tank 1103 is fixedly connected to the upper side. The control board 1104, a solar collector 1105 is fixedly connected to the upper part of the control board 1104, and a heating cleaning mechanism B is fixedly connected to the right side of the heating water tank 1103. It has the advantages of controlling the entrance and heating the entering asphalt. When the asphalt moves from the connecting plate on the left to the right, it will squeeze the middle of the connecting plate forward and then squeeze the push-pull plate. At this time, the push-pull plate pushes the spring telescopic column forward, and the asphalt starts to enter through the gap and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com