Low-carbon concrete and cementing material

A cementitious material and concrete technology, applied in the field of concrete, can solve the problems of reducing the carbon emission of concrete, difficult to guarantee the mechanical properties of concrete, and reducing the amount of cement, so as to reduce carbon emission, improve durability, improve water absorption and crushing. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

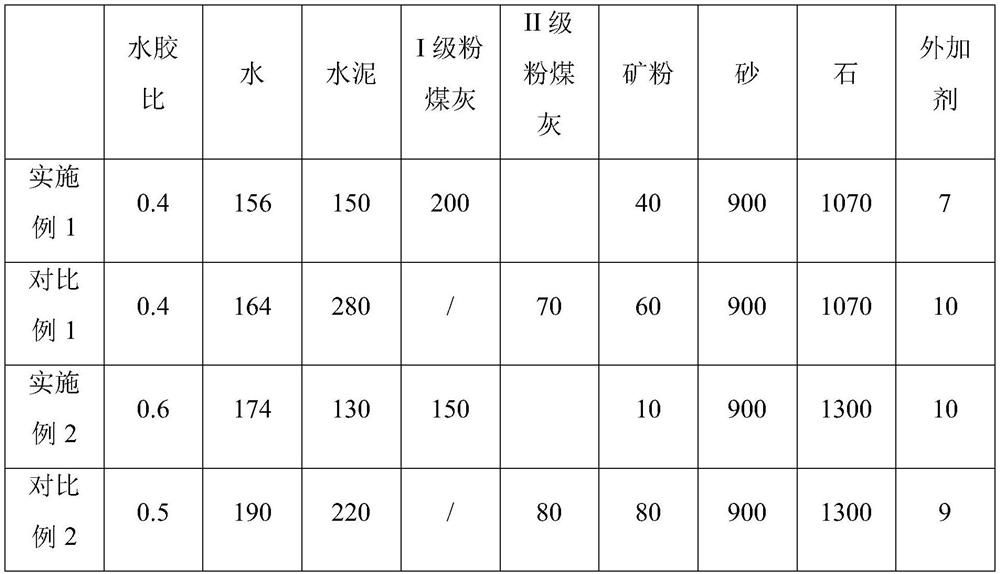

[0030] Embodiment 1: a kind of low carbon concrete, its proportion is as shown in table 1, and its preparation method is as follows:

[0031] 1) According to the formula of Example 1 in Table 1, weigh the required cement, first-grade fly ash, mineral powder, common sand, common stone, admixture and water.

[0032] 2) Rinse the mixer before mixing, and pre-mix a small amount of the same concrete mixture. After the inner wall of the mixer is hung with slurry, the remaining material is discharged.

[0033] 2) Put the weighed ordinary sand and ordinary stone in the mixer and stir, then add the weighed cement, first-grade fly ash and mineral powder into the mixer, turn on the mixer, and then add water and polycarboxylate water reducing agent. Add it to the mixer and mix for at least 2 minutes until it is evenly mixed, and then take out the machine to obtain a concrete mixture.

[0034] The slump test, slump loss over time test, expansion degree test and expansion degree loss over ...

Embodiment 2

[0064] Embodiment 2: a kind of low carbon concrete, its proportion is shown in table 1, and its preparation method is the same as embodiment 1.

[0065] The slump / expansion test and the compressive strength test of 7d, 28d, and 60d were carried out on the concrete of Example 2 using the same test method as in Example 1. The test results are shown in Table 2.

Embodiment 3

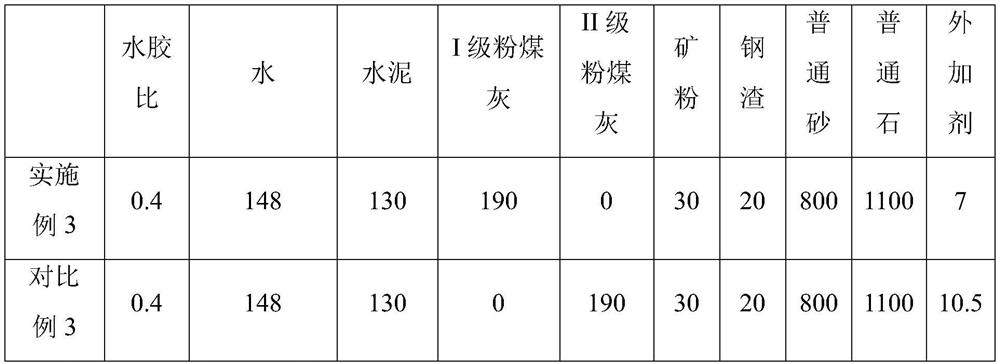

[0073] Embodiment 3: a kind of low carbon concrete, its proportion is shown in table 3, and its preparation method is the same as embodiment 1.

[0074] The slump / expansion test and the compressive strength test of 7d, 28d, and 60d were carried out on the concrete of Example 3 using the same test method as in Example 1. The test results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com