Flame-retardant polylactic acid composite material and preparation method thereof

A technology of composite materials and polylactic acid, which is applied in the field of flame-retardant polylactic acid composite materials and its preparation, can solve the problems of flame-retardant and physical properties that need to be improved, a single preparation method, and the inability to prepare polylactic acid composite materials. Promotional value, good flame retardancy and physical properties, and the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

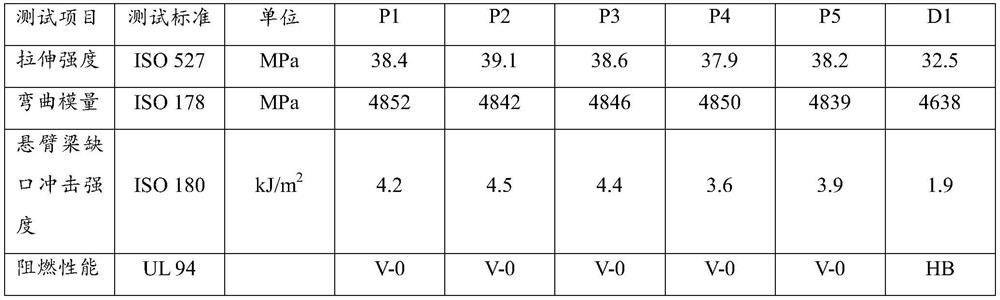

Examples

preparation example 1

[0029] (1) Weigh 10g of templating agent octadecyltrimethylammonium chloride, 200g of hydrochloric acid, 1.0kg of deionized water, 300g of cerium nitrate hexahydrate, and 180g of silico-molybdic acid, add them to a reaction vessel, and react with ultrasonic at 40°C for 6h , to form solution A;

[0030] (2) The solution A is filtered, washed and dried to obtain solid B.

[0031] (3) The solid B was calcined in a muffle furnace at 760° C. for 12 hours to obtain a high-performance flame retardant filler M1.

Embodiment 1

[0033] (1) Weigh 80 parts of polylactic acid, 18 parts of high-performance flame retardant filler M1, 0.1 part of antioxidant Irganox1010 and mix and stir to obtain a mixture;

[0034] (2) Extruding and granulating the mixture obtained in step (1) from an extruder to obtain a polylactic acid composite material P1.

[0035] Among them, the twin-screw extruder includes six temperature zones arranged in sequence, the temperature of the first zone is 180°C, the temperature of the second zone is 190°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 190°C, the temperature of the fifth zone is 190°C, and the temperature of the sixth zone is 190°C. The temperature is 190°C, the head temperature is 190°C, and the screw speed is 200r / min.

preparation example 2

[0037] (1) Weigh 30g of templating agent octadecyltrimethylammonium chloride, 300g of hydrochloric acid, 1.6kg of deionized water, 400g of cerium nitrate hexahydrate, 240g of silico-molybdic acid, put them into a reaction vessel, and react with ultrasonic at 60°C for 10h , to form solution A;

[0038] (2) The solution A is filtered, washed and dried to obtain solid B.

[0039] (3) The solid B was calcined in a muffle furnace at 820° C. for 16 hours to obtain a flame-retardant high-performance filler M2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com