Preparation method of antibacterial conductive polypropylene fiber yarn

A polypropylene yarn and polypropylene yarn technology is applied in yarn, rayon manufacturing, fiber processing and other directions to reduce raw material costs, solve static problems, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

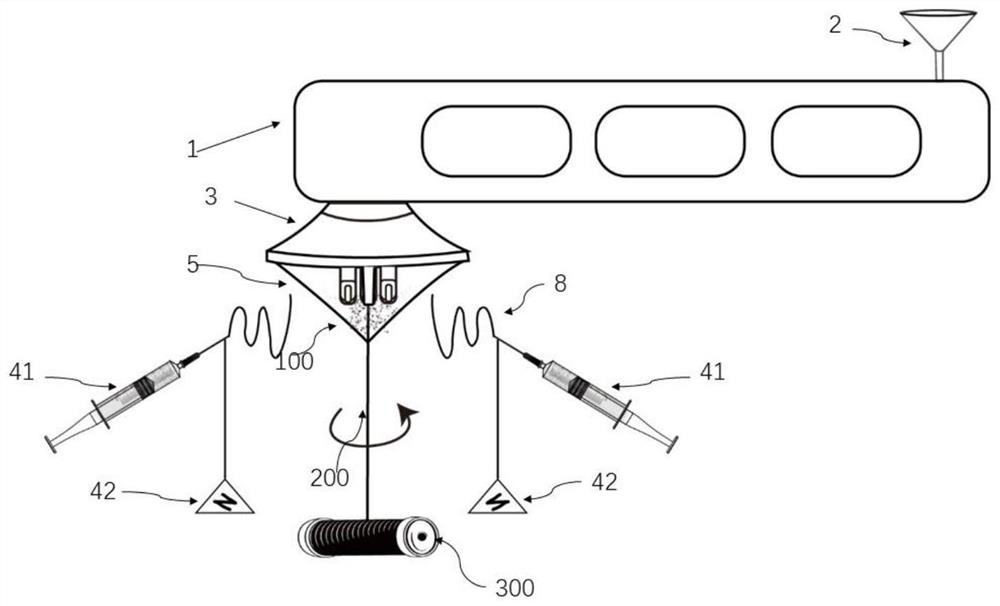

[0048] A preparation method of antibacterial conductive polypropylene yarn, specifically comprising the following steps:

[0049] The mass ratio of polypropylene particles and heat stabilizer caprolactam is 100:1 into the feed port of the melt spinning machine. After the polypropylene particles and heat stabilizer are melted inside the machine, they are melted and drawn, and the diameter of the melt spinneret is 6mm. , the spinning speed is 20m / min, and the wire temperature at the bell mouth is 170℃. The hot fuse is extruded and connected to the receiving device.

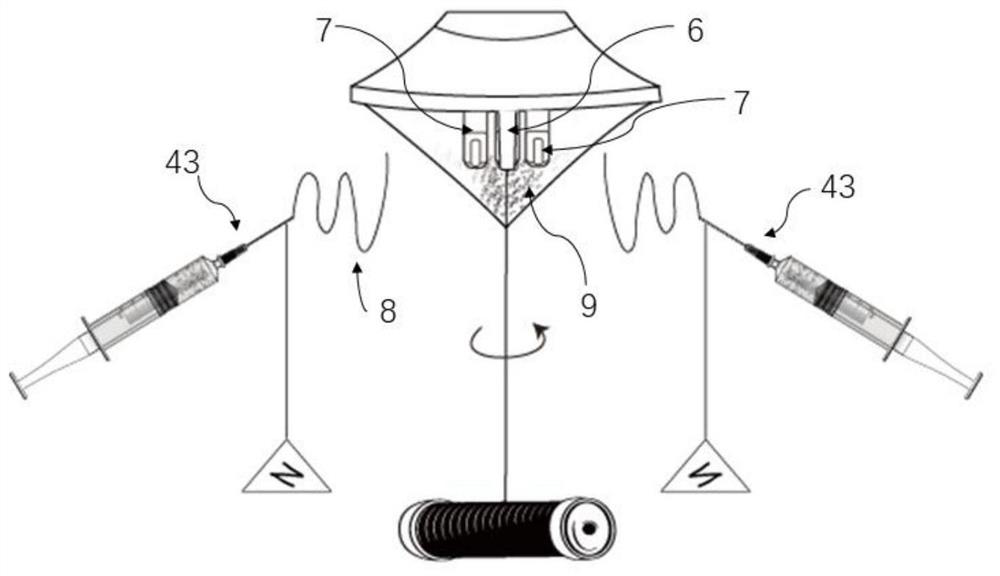

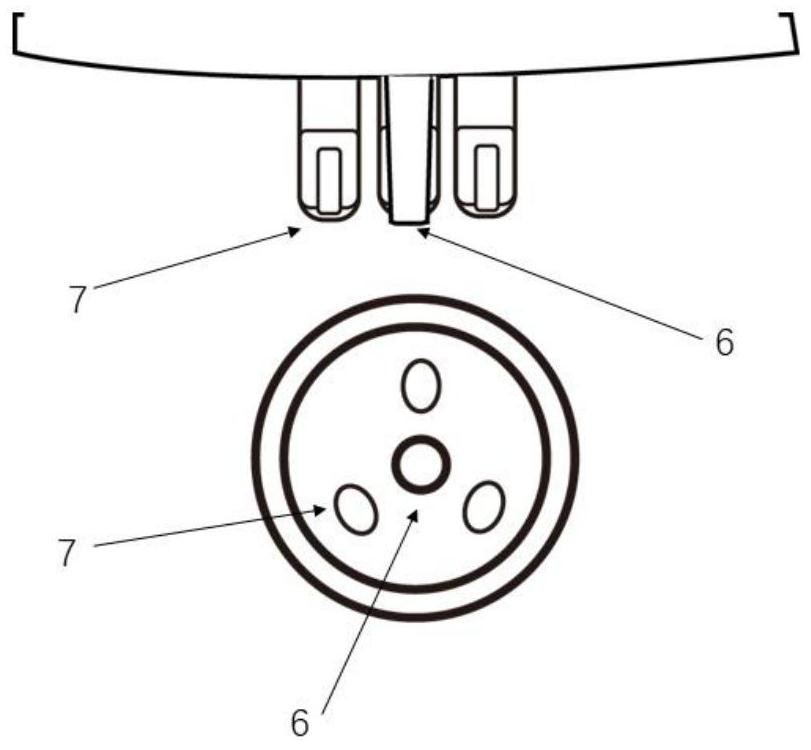

[0050] The chitosan / PVA spinning solution is extruded through the flat needle of the electrospinning machine through conjugate electrospinning, and uniformly drawn onto the polymer polypropylene fiber to form a tapered gauze surface. The electrospinning process parameters are: the mass fraction of polyvinyl alcohol in the chitosan / PVA spinning solution is 12%, the mass fraction of chitosan is 2%, and the two flat n...

Embodiment 2

[0054] A preparation method of antibacterial conductive polypropylene yarn, specifically comprising the following steps:

[0055] The mass ratio of polypropylene particles and heat stabilizer caprolactam is 100:1 into the feed port of the melt spinning machine. After the polypropylene particles and heat stabilizer are melted inside the machine, they are melted and drawn, and the diameter of the melt spinneret is 6mm. , the spinning speed is 20m / min, and the wire temperature at the bell mouth is 170℃. The hot fuse is extruded and connected to the receiving device.

[0056] The chitosan / PVA spinning solution is extruded through the flat needle of the electrospinning machine through conjugate electrospinning, and uniformly drawn onto the polymer polypropylene fiber to form a tapered gauze surface. The electrospinning process parameters are: the mass fraction of polyvinyl alcohol in the chitosan / PVA spinning solution is 12%, the mass fraction of chitosan is 2%, and the flat needl...

Embodiment 3

[0060] A preparation method of antibacterial conductive polypropylene yarn, specifically comprising the following steps:

[0061] The mass ratio of polypropylene particles and heat stabilizer caprolactam is 100:1 into the feed port of the melt spinning machine. After the polypropylene particles and heat stabilizer are melted inside the machine, they are melted and drawn, and the diameter of the melt spinneret is 6mm. , the spinning speed is 12m / min, and the wire temperature at the bell mouth is 170℃. The hot fuse is extruded and connected to the receiving device.

[0062] The chitosan / PVA spinning solution is extruded through the flat needle of the electrospinning machine through conjugate electrospinning, and uniformly drawn onto the polymer polypropylene fiber to form a tapered gauze surface. The electrospinning process parameters are: the mass fraction of polyvinyl alcohol in the chitosan / PVA spinning solution is 12%, the mass fraction of chitosan is 2%, and the flat needl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com