Intelligent optical observation and recognition system for flame-permeable wall surface of boiler

A technology of identification system and observation system, which is applied in the direction of boiler working status indication, safety device of combustion chamber, combustion method, etc., which can solve the problem of limited observation area, only observation of naked eye visible area and bright position, high risk of personnel safety, etc. problem, to achieve the effect of facilitating timely intervention, improving the scope of observation area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

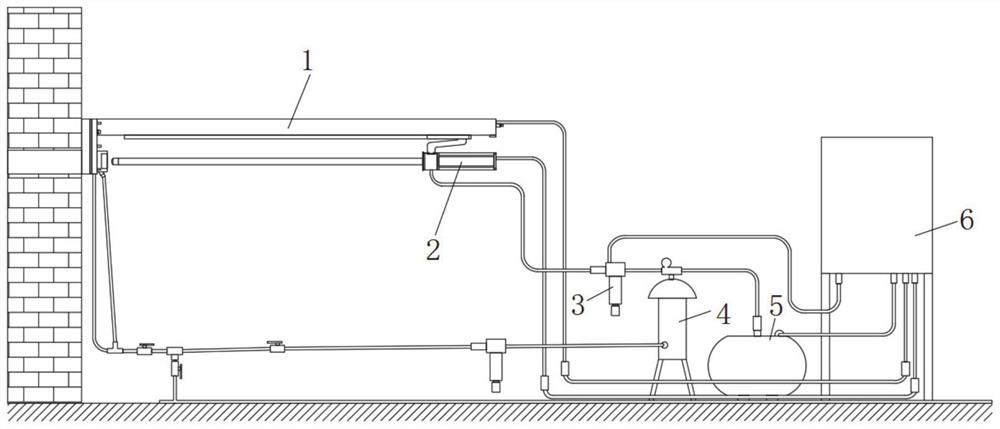

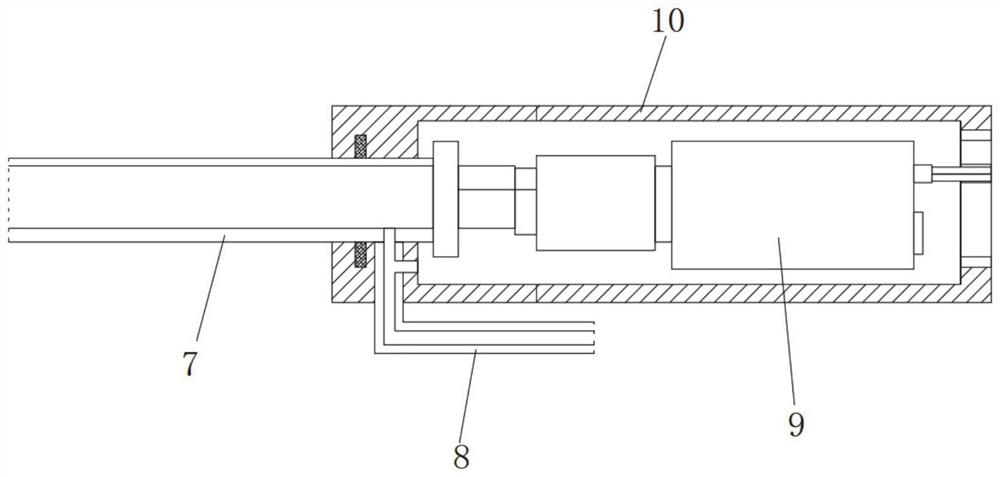

[0022] like Figures 1 to 2 As shown in the figure, an intelligent optical observation and identification system for the through-flame wall surface of a boiler includes an observation system body, and the observation system body includes an electric slide rail arranged on the outside of the boiler furnace wall, an observation device 2, a gas supply device, a control cabinet 6, an electric The slide rail 1 includes a slider, and an observation device 2 is arranged below the slider; the observation device 2 includes an infrared camera 9 and a camera protective cover 10. The camera protective cover 10 is provided with a hollow cavity, and an infrared camera 9 is arranged in the hollow cavity. The front part of the lens of the camera 9 is provided with a straight pipe section 7 for inserting into the observation window on the boiler furnace wall. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com