High-voltage line inspection device with foreign matter cleaning function

A high-voltage line and function technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of reducing the efficiency of inspection and easy to cause fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

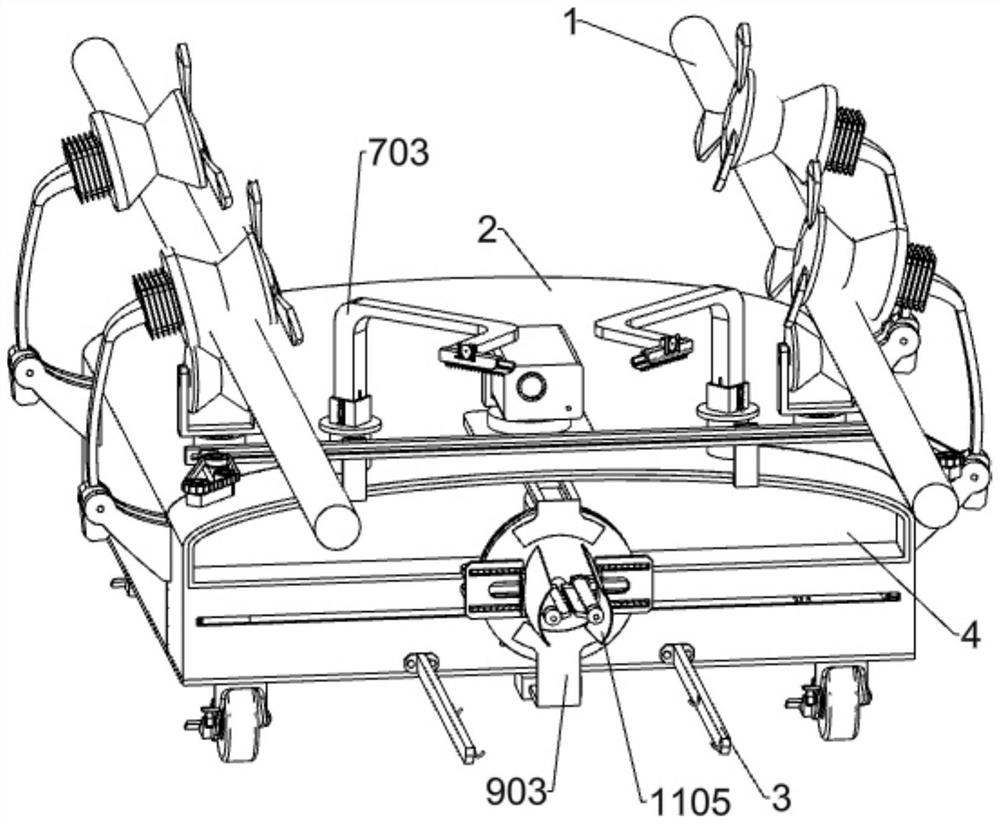

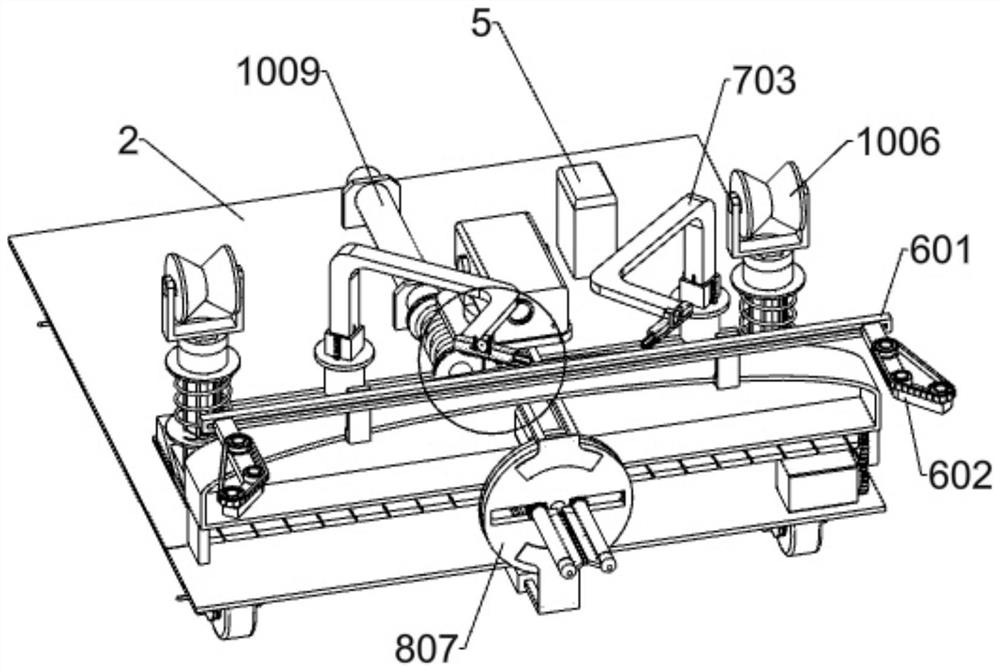

[0033] A high-voltage line inspection device with foreign body cleaning function, such as Figure 1-Figure 12 As shown, it includes an inspection device 2, the left and right parts of the front side of the inspection device 2 are fixed with support rods 3, and a net pocket for collecting plastic films is connected between the two support rods 3 through hooks. A first fixed shell 4 is embedded in the upper part of the front side, a control module 5 is fixedly connected to the right part of the inner upper side of the inspection device 2, and the control module 5 is signal-connected with the handheld control terminal in the hands of the operator. A film tightening mechanism is provided. The film tightening mechanism is used to bind and tighten the plastic film wound on the high-voltage cable. The film tightening mechanism is connected to the battery circuit in the inspection device 2 and is electrically connected to the control module 5. The upper part of the inspection device 2 ...

Embodiment 2

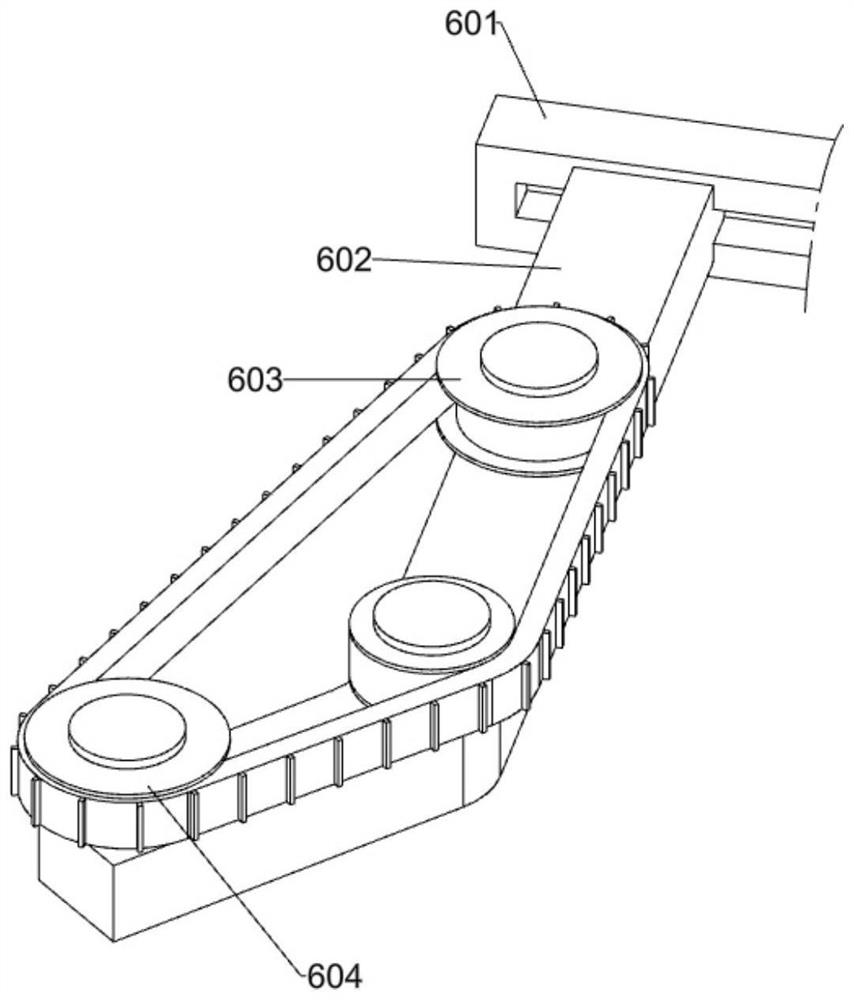

[0036] On the basis of Example 1, as image 3 As shown, the film tightening mechanism includes an electric sliding rail 601. The upper part of the front side of the inspection device 2 is fixedly connected with an electric sliding rail 601 through a mounting seat. 601 is connected to the battery circuit in the inspection device 2 and is electrically connected to the control module 5. The two electric sliders on the electric slide rail 601 are respectively fixed with support plates 602, and the two support plates 602 are inclined outwards. , the rear parts of the upper sides of the two support plates 602 are rotatably connected with electric wheels 603, and the two electric wheels 603 are connected with the battery circuit in the inspection device 2 and are electrically connected with the control module 5. The upper parts of the two support plates 602 A belt pulley 604 is rotatably connected to the front part of the side surface, and a guide pulley is rotatably connected to the...

Embodiment 3

[0051] On the basis of Example 2, when two high-voltage cables 1 on both sides are wrapped with a plastic film at the same time, the operator sends a signal to the control module 5 through the hand-held control terminal, and then the control module 5 starts the electric rotating shafts on both sides. 701, the electric rotating shafts 701 on both sides drive the other components on it to rotate to the outside, so that the blades on the lower sides of the sliding blocks 708 on the left and right sides are respectively located on the upper side of the adjacent high-voltage cables 1, and finally the operator controls the terminal by hand. Send a signal to the control module 5, and then the control module 5 starts the electric slide rail 601, and the electric slide rail 601 makes the electric slides on the left and right sides respectively drive the support plate 602 and other components on it to slide to the middle, so that through the two support plates 602 drives the belts wound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com